SVI 60-60 Graphite Outer Profile Cutting Machine

The SVI 60-60 is a CNC-controlled diamond wire cutting machine built for precise outer profile cutting of graphite blocks. It supports the creation of complex external shapes such as curves, angles, and custom outlines with high precision, low dust, and no chipping.

Engineered for advanced graphite machining tasks, the SVI 60-60 offers exceptional flexibility in shape definition and repeatability for production and prototyping needs.

Cutting Structure and Principle

Heavy-Duty Vertical Frame Structure

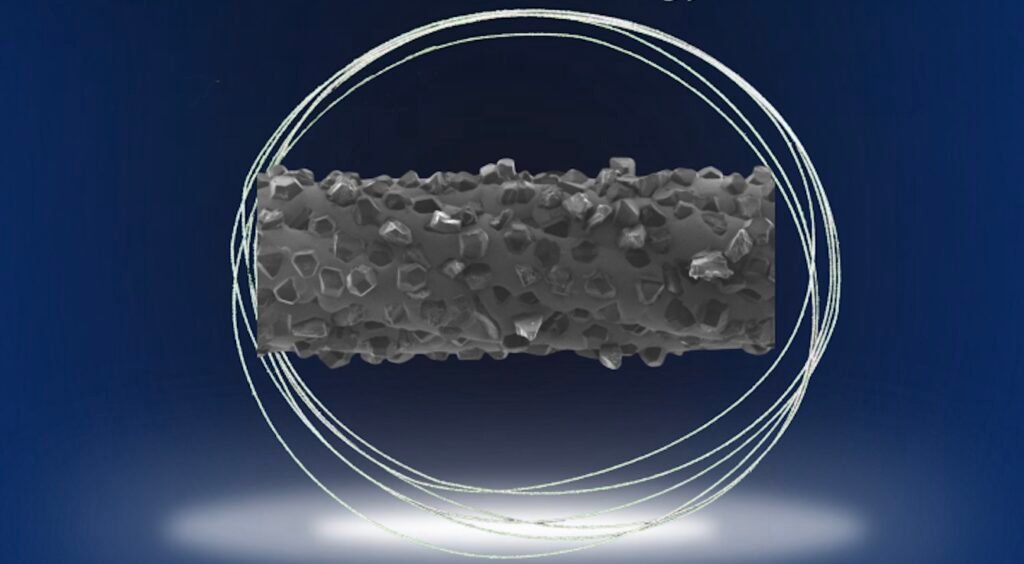

Built with a reinforced vertical gantry design to ensure stability during large-format slicing. The worktable moves precisely on high-precision linear rails under CNC control.Endless Diamond Wire Saw Technology

The machine uses a continuous-loop diamond wire for cutting. The wire moves unidirectionally at high speed, producing smooth, burr-free cuts with minimal material loss. This method eliminates reverse-stroke marks common in traditional wire saws.Key Features and Advantages

CNC Automatic Control

Fully automated worktable movement enables precise multi-slice operations with programmable thickness control.Large Workpiece Capacity

Capable of cutting graphite blocks up to 600mm × 600mm, ideal for large-scale graphite processing.High Cutting Precision

Achieves slicing accuracy up to ±0.05mm, suitable for applications requiring ultra-flat surfaces.Dual Cutting Modes

Supports both straight cut and complex shape cut, making it adaptable to different applications.Endless Wire Auto Tensioning System

Maintains consistent cutting pressure and wire stability throughout long operations.Low Dust, Clean Cutting Process

The continuous unidirectional motion reduces vibration and dust generation, ideal for cleanroom environments.Smart Operation Interface

Equipped with a touchscreen for intuitive operation, parameter input, and process monitoring.Durable and Easy to Maintain

Industrial-grade components and modular design ensure long service life and simplified maintenance.

SVI 60-60 TECHNICAL SPECIFICATION

| No. | Name | Specification |

| 1 | Maximum Workpiece Length (mm) | 600 |

| 2 | Maximum Workpiece Width (mm) | 600 |

| 3 | Maximum Workpiece Height (mm) | 600 |

| 4 | Worktable X-Axis Travel (mm) | 600 |

| 5 | Worktable Y-Axis Travel (mm) | 600 |

| 6 | Maximum Diamond Wire Speed (m/s) | 84 |

| 7 | Minimum Feed Increment X-Axis (mm) | 0.01 |

| 8 | Minimum Feed Increment Y-Axis (mm) | 0.01 |

| 9 | Repeat Positioning Accuracy X-Axis (mm) | 0.01 |

| 10 | Repeat Positioning Accuracy Y-Axis (mm) | 0.01 |

| 11 | Total Power Consumption (kW) | 2.2 |

| 12 | Power Supply | 380V 50Hz |

| 13 | Machine Size(mm) | 2200*2200*1900 |

| 14 | Machine Weight(kg) | 2000 |

| 15 | Air Pressure(MPa) | 0.65 |

3 Functions of This Graphite 0uter ProfileCutting Machine

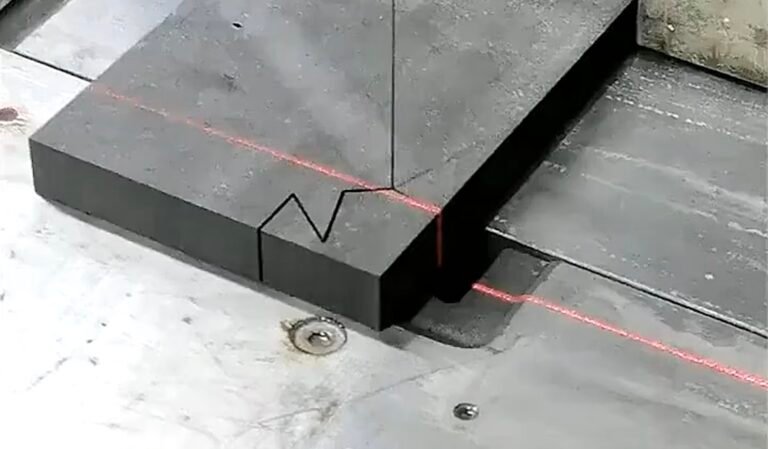

CNC Graphite Contour Cutter SVI60-60 Customer On-site Cutting Effect Showcase

Comparison Between Diamond Band Saw and a Single Diamond Wire Saw

Aspect | Diamond Band Saw | Endless Diamond Wire Saw |

Cutting Mechanism | Utilizes a continuous loop of diamond-coated band as the cutting tool. | Employs a continuous loop of diamond-coated wire as the cutting tool. |

Cutting Speed | Generally slower cutting speed due to the movement of the band. | Faster cutting speed due to the continuous linear motion of the wire. |

Kerf Width | Typically has a wider kerf width, leading to more material wastage. | Minimizes kerf width, resulting in minimal material wastage. |

Cut Surface Quality | May require additional polishing steps to achieve a smooth finish. | Simultaneously cuts and polishes, ensuring a smooth and shiny surface. |

Versatility | Suitable for basic cuts and straight lines. | Highly versatile, suitable for complex shapes and intricate designs. |

Precision | Moderate precision; may not achieve intricate designs accurately. | Offers high precision, ideal for intricate graphite components. |

Material Efficiency | Can be less material-efficient due to wider cuts. | Maximizes material efficiency with narrow cuts. |

Dust Generation | Generates more dust, potentially requiring dust extraction systems. | Produces minimal dust, contributing to a cleaner working environment. |

Application | Mainly used for simpler cutting tasks | Ideal for various cutting needs, especially intricate graphite parts. |

Ideal Use Case | Basic straight cuts in graphite. | Precision cuts, intricate designs, and complex graphite components. |

COMPARISON OF THE CUT SURFACE EFFECT

CUTTING APPLICATIONS

Large Block Graphite Slicing

Precisely slicing thick and oversized graphite blocks into uniform slabs with minimal kerf loss.

Ideal for EDM graphite electrodes, semiconductor base plates, and high-temperature structural components.

Graphite Inner Contour Cutting

Creating intricate internal profiles such as holes, slots, and cavities within graphite materials.

Suitable for customized electrode manufacturing and specialized electronic parts production.

Graphite Outer Profile Cutting

Shaping complex external outlines, including circles, irregular frames, and custom geometries.

Perfect for producing graphite molds, fixtures, and battery components.

Multi-Slice High-Throughput Cutting

Enabling efficient multi-slice operations for mass production of graphite sheets for lithium battery anodes and solar cell backplanes.

GRAPHITE WIRE SAW MACHINE ADVANTAGE

High-Speed Endless Wire Cutting

High-Rigidity Cast Structure

High-Precision Guide Rails and Ball Screw

Automatic Constant-Tension System

Micron-Level Feed Control

User-Friendly Smart Interface

Fully Enclosed Protective Design (Optional)

Low Maintenance & Cost Efficiency

Modular Design

Low Maintenance & Cost Efficiency

Automatic Lubrication System

Customer Testimonials

Frequently Asked Questions

What is the maximum thickness the machine can handle for cutting?

What is the difference between this wire saw and BAND SAW?

The cutting speed would be similar, but wire saw’s cut surface quality is far more better. and the kerf loss is smaller.