Achieving a clean and smooth surface finish in graphite cutting is crucial for many industrial applications, including EDM (Electrical Discharge Machining), mold making, and precision components. High-quality surface finishes not only improve product performance but also enhance durability and accuracy. To achieve optimal results, specific parameters must be carefully managed and optimized during the cutting process.

In this article, we explore the essential parameters for achieving clean graphite surface finishes and how each one contributes to superior cutting quality.

1. Wire Tension and Cutting Speed Control

One of the foundational parameters in graphite cutting is the wire tension and cutting speed:

- Wire Tension: Consistent wire tension is crucial to prevent vibrations that cause surface irregularities and micro-cracking. When the wire tension is too loose, it can lead to wavy cuts and rough edges. Conversely, excessive tension may increase the risk of wire snapping and damage to the workpiece.

- Cutting Speed: A controlled cutting speed reduces friction and heat generation, which are common causes of surface imperfections. Slower speeds are generally recommended for achieving finer surface finishes, while faster speeds are suitable for bulk material removal.

Regular monitoring and adjustments during operation ensure smoother cuts and prolong wire life, ultimately resulting in cleaner surface finishes.

2. Coolant Application for Surface Integrity

Cooling systems play a significant role in maintaining surface quality during graphite cutting:

- Dust Suppression: Graphite is known for generating fine dust during machining. Proper coolant application minimizes dust accumulation, preventing surface contamination and micro-scratches.

- Heat Dissipation: Effective coolant flow helps manage heat generated during cutting, reducing thermal stress that can lead to surface defects.

- Lubrication: Adequate lubrication minimizes friction, leading to smoother finishes and enhanced material integrity.

High-quality coolants designed specifically for graphite applications help maintain surface integrity and extend equipment lifespan.

3. Abrasive Grit Selection for Precision Finishes

The abrasive grit size of the diamond wire saw is another critical factor:

- Fine Grit (D20-D40): Ideal for achieving smooth, clean finishes on graphite surfaces, especially for precision components.

- Medium Grit (D50-D80): Provides a balance between cutting speed and surface smoothness, suitable for general applications.

- Coarse Grit (D100+): Allows for faster material removal but may increase surface roughness.

Selecting the appropriate grit size based on application requirements optimizes surface finish and cutting efficiency.

4. Machine Stability and Alignment

For consistent surface quality, machine stability and precision alignment are essential:

- Vibration Control: Minimizing mechanical vibrations helps avoid surface irregularities during cutting.

- Precision Alignment: Regular calibration of the wire saw ensures accurate cutting paths, reducing edge chipping and surface defects.

- Servo Mechanisms: Advanced control systems maintain optimal wire tension and cutting precision during operation.

Stable machinery and routine maintenance are key to achieving fine surface finishes in graphite cutting.

5. Environmental Control for Optimal Results

The working environment also influences the quality of graphite surface finishes:

- Temperature Regulation: Stable ambient temperatures prevent thermal expansion or contraction that could affect cutting accuracy.

- Dust Extraction Systems: Proper dust control reduces the risk of surface contamination and scratches.

- Humidity Control: Maintaining optimal humidity levels prevents graphite oxidation and surface imperfections.

A controlled environment helps maintain graphite’s structural integrity and cutting precision.

Conclusion

Optimizing key parameters—such as wire tension, coolant application, abrasive selection, machine stability, and environmental control—is critical for achieving clean graphite surface finishes. By fine-tuning these factors, manufacturers can enhance surface smoothness, reduce defects, and improve overall efficiency.

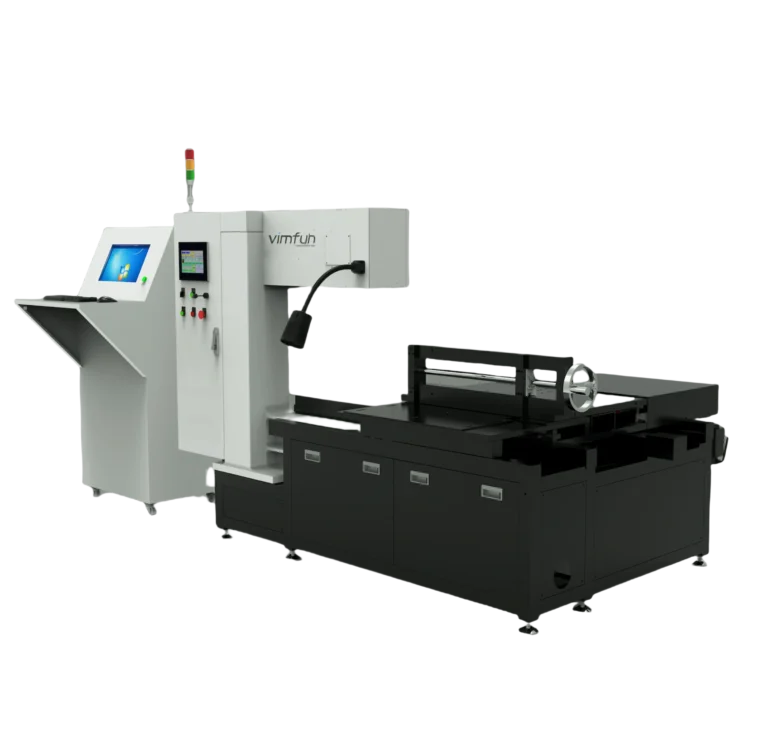

👉 Click here to explore our diamond wire saw machines designed for precision graphite cutting.