Graphite cutting is a key process in industries such as electronics, aerospace, and energy storage. However, one of the most persistent challenges in graphite machining is controlling the fine, dry carbon dust that is produced during cutting. Dust not only affects product quality but also poses serious risks to equipment longevity and worker health.

In high-precision graphite cutting, effective dust control is even more critical. Achieving clean, accurate cuts while maintaining a safe and efficient working environment requires both the right equipment and optimized operational practices. This article explores practical strategies to minimize dust generation during graphite processing.

1. Understanding Graphite Dust and Its Impact

Graphite is a brittle material that sheds fine particles when machined. These particles are extremely small and light, making them prone to airborne dispersion. Without proper containment, graphite dust can:

- Settle on machines, leading to accelerated wear or short-circuits in electronic components

- Enter operator airways, potentially causing respiratory irritation or long-term health risks

- Compromise surface finish and dimensional accuracy by contaminating the work area

In high-precision applications such as EDM electrodes, battery materials, or semiconductor tooling, even a small amount of dust contamination can lead to rework or component rejection.

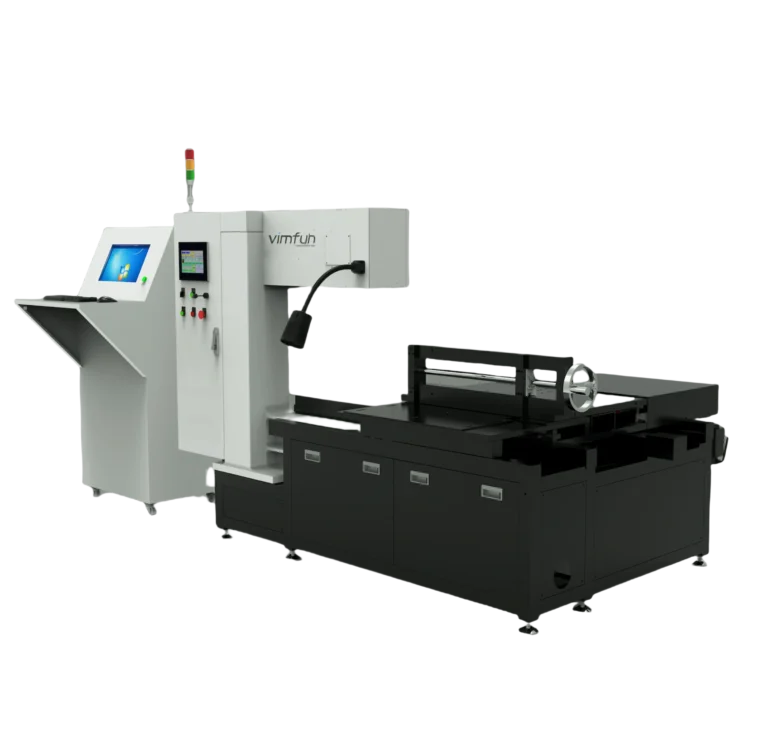

2. Choose the Right Cutting Technology: Diamond Wire Saw Advantage

One of the most effective ways to control dust is to start with the right cutting equipment. Compared to conventional tools like band saws or CNC mills, diamond wire saws offer significant benefits in dust reduction:

- Friction-reducing design: The thin wire and abrasive cutting action produce less mechanical stress, which reduces particle generation.

- Coolant compatibility: Diamond wire saws are often equipped with water-based or oil-based cooling systems that trap dust at the source.

- Smooth cut action: The continuous motion of the wire leads to less chipping and flaking, which directly lowers airborne dust.

👉 Click here to explore our diamond wire saw machines designed for precision graphite cutting.

For clean and precise graphite cuts, particularly in enclosed or temperature-sensitive environments, wire saw technology is a strong choice.

3. Implement Wet Cutting Techniques for Dust Suppression

Wet cutting is one of the most direct and reliable methods of suppressing dust during graphite machining. In this approach, a liquid coolant—typically water or a light oil—is applied continuously to the cutting zone.

Benefits of wet cutting include:

- Immediate dust capture: Moisture binds with airborne particles before they disperse.

- Cooling effect: It prevents overheating, reducing thermal degradation of graphite and extending tool life.

- Improved surface quality: Lubrication helps reduce micro-fractures and rough edges.

When designing or operating a graphite cutting station, ensure that fluid delivery nozzles are accurately positioned to cover the cutting path and that there’s an effective filtration and recirculation system in place.

4. Use Enclosed Cutting Chambers and Localized Extraction

To further contain dust, high-precision graphite cutting systems should use enclosed workspaces combined with local extraction units, such as:

- HEPA-filtered vacuum systems that pull dust directly from the cutting area

- Sealed cutting chambers that isolate the process from the operator and surrounding environment

- Negative pressure enclosures to ensure that dust does not escape into the ambient air

These systems not only protect operators but also help maintain compliance with occupational safety regulations. In cleanroom settings, such setups are often a requirement rather than an option.

5. Optimize Cutting Parameters to Reduce Dust Generation

Sometimes, dust production is a symptom of incorrect cutting parameters. For graphite machining, adjusting the following can yield cleaner results:

- Cutting speed: Slower speeds may produce less dust by minimizing friction and breakage

- Feed rate: Consistent, smooth feeding reduces stress and chipping

- Tool sharpness: Dull tools generate more dust due to excessive force and tearing

For CNC-guided processes, software settings can also be tuned to reduce tool chatter, which is a known cause of particle generation during high-precision operations.

6. Regular Maintenance and Workspace Cleanliness

No dust control system is complete without proper maintenance routines. Even with enclosed systems, residual dust can accumulate over time and cause problems. Best practices include:

- Frequent cleaning of machines, filters, and coolant tanks

- Scheduled inspection of dust extraction and ventilation systems

- Use of anti-static surfaces to prevent dust from adhering to machines or walls

Establishing daily and weekly cleaning checklists ensures the long-term performance of both your machinery and your dust control measures.

Conclusion: A Systematic Approach to Clean Graphite Cutting

Minimizing dust during high-precision graphite cutting is not about a single solution but rather a combination of smart equipment choices, optimized processes, and ongoing maintenance. The following integrated approach works best:

- Choose diamond wire saws with wet cutting capability

- Use enclosed cutting stations and localized dust extraction systems

- Tune cutting parameters to reduce breakage

- Maintain a clean workspace through routine care

With these practices in place, manufacturers can achieve accurate, clean, and safe graphite machining—essential for industries where quality and compliance are non-negotiable.