SVR 50-50 Rotary Graphite Cutting Machine

The SVR 50-50 is a CNC diamond wire cutting machine engineered for rotational slicing of cylindrical graphite components. With support for fully automatic rotation, programmable feed, and dry cutting mode, it offers a clean, efficient solution for reshaping graphite rods, crucibles, and tube-like blocks into square or flat workpieces.

Ideal for applications that require dimensional transformation without material chipping or deformation.

Cutting Technology & Advantages

Endless Diamond Wire System

Enables smooth, single-direction abrasive cutting with minimal kerf loss.Fully Automated Rotation

The machine automatically rotates cylindrical graphite blocks during slicing for uniform thickness and concentric precision.Dry Cutting Mode

No coolant required — cleanroom-friendly and ideal for environments where dust control and simplicity are key.Programmable Feed Motion

Allows for precise control over slice thickness, multi-pass cutting, and batch automation.Universal Pneumatic Clamping

A top-down pneumatic fixture holds round blocks securely, minimizing vibration and enabling safe, accurate cutting. Custom clamping solutions are also available.

SVR 50-50 TECHNICAL SPECIFICATION

| No. | Name | Specification |

| 1 | Maximum Workpiece Length (mm) | 500 |

| 2 | Maximum Workpiece Width (mm) | 500 |

| 3 | Maximum Workpiece Height (mm) | 450 |

| 4 | Worktable X-Axis Travel (mm) | 500 |

| Worktable Y-Axis Travel (mm) | 500 | |

| 5 | Maximum Diamond Wire Speed (m/s) | 40 |

| 6 | Minimum Feed Increment X-Axis (mm) | 0.01 |

| 7 | Minimum Feed Increment Y-Axis (mm) | 0.01 |

| 8 | Repeat Positioning Accuracy X-Axis (mm) | 0.01 |

| 9 | Repeat Positioning Accuracy Y-Axis (mm) | 0.01 |

| 10 | Total Power Consumption (kW) | 3.7 |

| 11 | Power Supply | 380V 50Hz |

| 12 | Machine Size(mm) | 1800*1200*1700 |

| 13 | Machine Weight(kg) | 1800 |

| 14 | Air Pressure(MPa) | 0.65 |

📐 Technical Specifications

| Parameter | Value |

|---|---|

| Max Workpiece Diameter | 500 mm |

| Max Workpiece Height | 500 mm |

| Cutting Mode | Dry Cutting |

| Rotation | Fully Automatic |

| Feed System | Programmable CNC Control |

| Wire Type | Endless Diamond Wire |

| Clamping | Pneumatic Top-Down Clamp (customizable) |

| Control Interface | Touchscreen CNC Panel |

| Wire Diameter | 0.35–0.45 mm |

Real Cutting Footage / User Site Video

Comparison Between Diamond Band Saw and a Single Diamond Wire Saw

Aspect | Diamond Band Saw | Endless Diamond Wire Saw |

Cutting Mechanism | Utilizes a continuous loop of diamond-coated band as the cutting tool. | Employs a continuous loop of diamond-coated wire as the cutting tool. |

Cutting Speed | Generally slower cutting speed due to the movement of the band. | Faster cutting speed due to the continuous linear motion of the wire. |

Kerf Width | Typically has a wider kerf width, leading to more material wastage. | Minimizes kerf width, resulting in minimal material wastage. |

Cut Surface Quality | May require additional polishing steps to achieve a smooth finish. | Simultaneously cuts and polishes, ensuring a smooth and shiny surface. |

Versatility | Suitable for basic cuts and straight lines. | Highly versatile, suitable for complex shapes and intricate designs. |

Precision | Moderate precision; may not achieve intricate designs accurately. | Offers high precision, ideal for intricate graphite components. |

Material Efficiency | Can be less material-efficient due to wider cuts. | Maximizes material efficiency with narrow cuts. |

Dust Generation | Generates more dust, potentially requiring dust extraction systems. | Produces minimal dust, contributing to a cleaner working environment. |

Application | Mainly used for simpler cutting tasks | Ideal for various cutting needs, especially intricate graphite parts. |

Ideal Use Case | Basic straight cuts in graphite. | Precision cuts, intricate designs, and complex graphite components. |

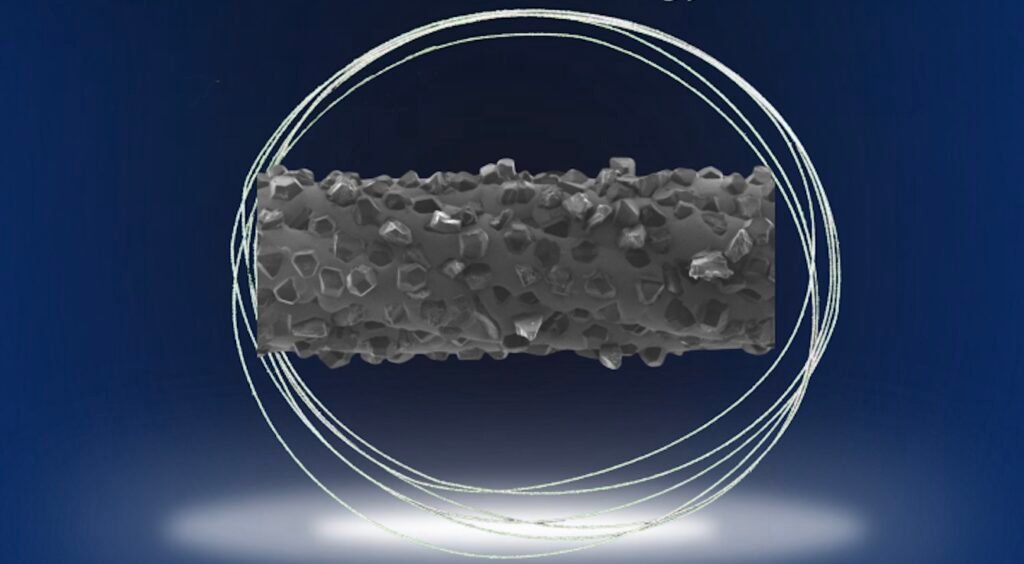

COMPARISON OF THE CUT SURFACE EFFECT

THE ADVANTAGES OF OUR MACHINE

High-Speed Endless Wire Cutting

High-Rigidity Cast Structure

High-Precision Guide Rails and Ball Screw

Automatic Constant-Tension System

Micron-Level Feed Control

User-Friendly Smart Interface

Fully Enclosed Protective Design (Optional)

Low Maintenance & Cost Efficiency

Modular Design

Low Maintenance & Cost Efficiency

Automatic Lubrication System

Customer Testimonials

Frequently Asked Questions

What is the maximum thickness the machine can handle for cutting?

What is the difference between this wire saw and BAND SAW?

The cutting speed would be similar, but wire saw’s cut surface quality is far more better. and the kerf loss is smaller.