El grafito es un material especial que se utiliza en muchas industrias. Desempeña un papel fundamental en la fabricación de piezas para la electrónica, la industria aeroespacial, moldes, etc. Para utilizar el grafito correctamente, hay que cortarlo con cuidado y precisión. Ahí es donde la precisión cortadora vertical de grafito viene en. Esta máquina ayuda a cortar bloques u hojas de grafito en formas limpias y rectas en todo momento. Ahorra tiempo, reduce los residuos y garantiza que el producto final cumpla las normas más estrictas.

También le explicaremos cómo elegir la máquina adecuada y por qué Vimfun es uno de los mejores proveedores en este campo.

Cortadora vertical de grafito de alto rendimiento disponible

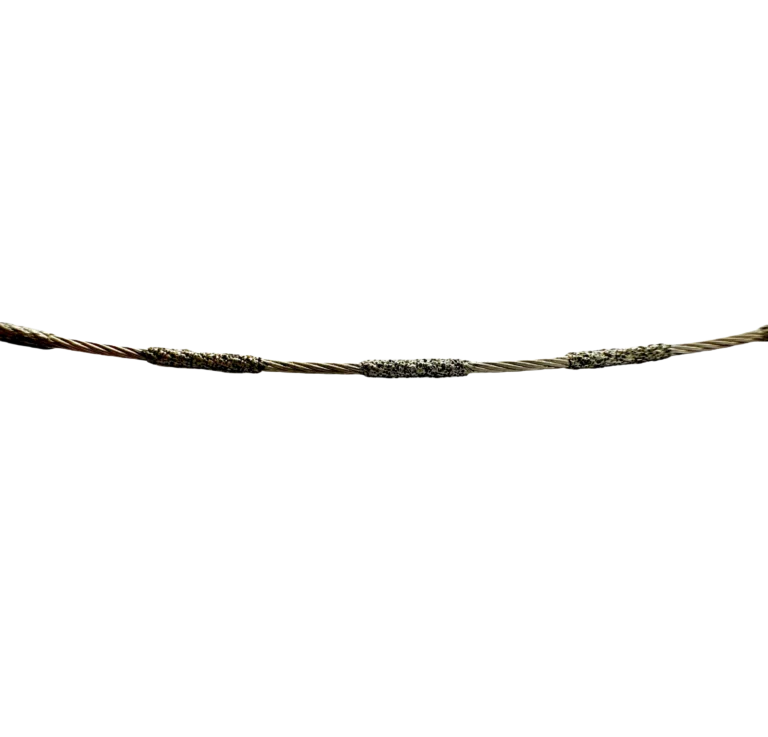

En Máquina vertical de corte de grafito SV 60-60 está diseñada para cortar bloques de grafito de tamaño medio a grande con gran precisión y un desperdicio mínimo. Su diseño vertical ahorra espacio en el suelo y permite cargarla fácilmente por delante o por arriba. Esta máquina compacta utiliza un hilo de diamante continuo que se mueve en una dirección a gran velocidad, creando cortes suaves y limpios sin rebabas ni marcas.

En SV 60-60 Entre sus capacidades se incluye el control automático CNC para un grosor de corte particular y programable. Puede trabajar con grandes bloques de grafito de hasta 600 mm, lo que la hace perfecta para grafito de baterías, bloques de electroerosión y planchas de grafito para moldes. La sujeción asistida por gravedad de la máquina mantiene la pieza estable y reduce las vibraciones durante el corte.

¿Qué es una máquina vertical de corte de grafito?

A cortadora vertical de grafito es una herramienta diseñada específicamente para cortar materiales de grafito con la cuchilla o el hilo de corte moviéndose verticalmente. A diferencia de las cortadoras horizontales, las verticales mantienen el bloque de grafito en posición vertical. La herramienta de corte se desplaza hacia abajo a través del material para realizar cortes precisos.

Este diseño permite un mejor control y precisión al cortar piezas de grafito altas o gruesas. La configuración vertical también ayuda a eliminar eficazmente el polvo y los residuos, manteniendo limpio el espacio de trabajo. Estas máquinas se gestionan regularmente mediante sistemas CNC para garantizar medidas específicas y cortes regulares.

El método de corte vertical es ideal para realizar cortes instantáneos en grafito utilizado en moldes, electrodos y diferentes piezas comerciales en las que se requiere precisión.

¿Cómo garantiza una cortadora vertical cortes limpios?

A Máquina vertical de corte de grafito utiliza varias capacidades inteligentes para proporcionar cortes limpios y rectos. A menudo utiliza un cordón o cuchilla de diamante. Los diamantes son muy resistentes y pueden cortar el grafito suavemente sin astillarse ni agrietarse.

El aparato sujeta firmemente el bloque de grafito para evitar que se mueva durante el corte. Mueve el cable de corte o la cuchilla directamente hacia abajo con un movimiento constante y controlado. De este modo se evitan tambaleos y bordes irregulares.

La mayoría de las máquinas también utilizan la generación CNC. En este método, la dirección de corte se programa y gestiona mediante un ordenador. El aparato CNC garantiza que cada reducción siga el diseño preciso. También ajusta el ritmo y la presión para adaptarse a la dureza del grafito.

Una máquina de refrigeración rocía agua o refrigerante para evitar que el grafito y la cuchilla se sobrecalienten. El sobrecalentamiento puede causar bordes duros o daños. La máquina de refrigeración facilita la sujeción de un suelo liso y reducido.

Todos esos elementos trabajan en conjunto para proporcionar cortes fáciles, nítidos e inmediatos en todo momento, lo que es vital para los elementos de grafito de alta calidad.

Características principales de la sierra vertical CNC para grafito

Precisión cortadoras de bloques de grafito vienen con características únicas que las hacen destacar. Tienen un marco de alta resistencia. Esto continúa la fuerza del gadget en el curso de rebanar y previene las vibraciones que podrían destruir el reducir.

Utilizan alambres o cuchillas de corte recubiertos de diamante. El recubrimiento de diamante aumenta la robustez y la energía de corte. También facilita la realización de cortes más suaves con mucho menos desgaste de la herramienta.

Las máquinas suelen incluir un sofisticado sistema de gestión CNC. Con él, podemos manejar y programar trayectorias de corte específicas. Garantiza que cada corte coincida perfectamente con el trazado.

Un dispositivo de vacío o pinza sujeta firmemente el bloque de grafito. De este modo, el material se mantiene constante y se garantiza la seguridad durante todo el proceso de corte.

Estas máquinas incorporan un dispositivo de refrigeración y eliminación de polvo. Rocía refrigerante para reducir el calor y captura la suciedad de grafito, preservando la región de trabajo limpia y segura para los empleados.

Muchas cortadoras verticales tienen velocidades de corte y tensiones de hilo ajustables. Esta flexibilidad permite que el sistema funcione perfectamente con tipos y grosores de grafito exclusivos.

Todas estas funciones garantizan una gran precisión, seguridad y una larga vida útil de los dispositivos.

Ventajas del uso de máquinas verticales de corte de grafito en la industria

Industrias que utilizan equipos de corte de grafito de alta precisión obtener muchas ventajas.

- Una de las mayores ventajas es la precisión. La máquina de corte vertical puede realizar cortes específicos que se adaptan perfectamente al producto final. Esto reduce los errores y mejora la excepcionalidad del producto.

- Otra ventaja es el ahorro de tiempo. La máquina trabaja más rápido que las cortadoras guía y puede funcionar continuamente con mucho menos cansancio para el operario. Esto acelera la fabricación y reduce los gastos de mano de obra.

- El uso de este artilugio también reduce el desperdicio de tela. Como los cortes son suaves y auténticos, se desperdicia mucho menos grafito en bordes ásperos o errores.

- La disposición vertical permite mejorar la protección. La máquina de eliminación de suciedad reduce la cantidad de partículas de grafito suspendidas en el aire, protegiendo a los trabajadores de la inhalación de polvo peligroso.

- Las máquinas también son flexibles. Pueden reducir numerosas configuraciones y dimensiones, lo que las hace útiles para montones de envases, desde la electrónica hasta la fabricación de moldes.

Las cortadoras verticales de grafito son, en última instancia, muy rentables. Aunque requieren una inversión, reducen los errores, los residuos y el tiempo de inactividad, lo que permite ahorrar dinero de forma habitual.

Aplicaciones comunes de las máquinas de corte vertical de grafito

Las máquinas verticales de corte de grafito se utilizan en muchas industrias. En la industria electrónica, ayudan a cortar piezas de grafito para baterías y semiconductores. Estas piezas deben ser muy precisas para funcionar correctamente.

En el sector aeroespacial, el grafito se utiliza en piezas de alta temperatura y alta resistencia. Las cortadoras verticales dan a estas piezas la forma exacta que necesitan los reactores y las naves espaciales.

La industria de fabricación de moldes utiliza moldes de grafito para la fundición de metales. Las máquinas de corte vertical producen moldes lisos que mejoran la calidad de la fundición.

En la fabricación de automóviles, las piezas de grafito ayudan a controlar el calor y la electricidad en motores y baterías. Las cortadoras verticales garantizan que estas piezas encajen a la perfección.

Incluso los laboratorios de investigación utilizan estas máquinas para preparar muestras de grafito para pruebas y desarrollo.

Cómo elegir la herramienta de corte vertical de grafito adecuada

Elegir bien sistema de corte vertical de planchas de grafito depende de sus deseos concretos.

No olvide el tamaño y el grosor del grafito que necesita reducir. Asegúrese de que el aparato puede trabajar con las piezas más grandes.

Piense en el grado de precisión que necesita. Si sus elementos quieren tolerancias muy ajustadas, seleccione un dispositivo con controles CNC avanzados y una construcción sólida.

Fíjese en la velocidad de corte. Las máquinas más rápidas pueden mejorar la producción, pero pueden costar un poco más. Equilibre el ritmo con su presupuesto y sus deseos de producción.

Busque máquinas con estructuras antipolvo y de refrigeración exactas para mantener el espacio de trabajo seguro y los elementos lisos.

Recuerda la reputación y la asistencia del fabricante. Una atención al cliente fiable y una conservación limpia son esenciales para un uso prolongado.

Tener en cuenta estos puntos le ayudará a elegir un producto satisfactorio. Máquina vertical de corte de grafito para su negocio.

Su proveedor de confianza de maquinaria industrial de corte de grafito

Cuando se trata de máquinas de corte vertical de grafitoVimfun es un nombre en el que puede confiar. Se trata de un fabricante tecnológico especializado en máquinas de corte con hilo de diamante CNC para grafito.

Las máquinas Vimfun están construidas con la tecnología más avanzada. Ofrecen alta precisión, cortes suaves y un rendimiento fiable. Sus máquinas están diseñadas para satisfacer las estrictas necesidades de industrias como la electrónica, la aeroespacial y la de fabricación de moldes.

También ofrecen un excelente servicio de atención al cliente y formación. Le ayudan a elegir la máquina adecuada y le guían durante la instalación y el funcionamiento.

Su compromiso con la calidad significa que usted obtiene una máquina que dura mucho y funciona eficazmente todos los días. Muchas empresas de todo el mundo confían en ellos para sus necesidades de corte de grafito.

Elegir Vimfun significa elegir precisión, fiabilidad y servicio, todo en un mismo paquete.