Fournisseur de machines de découpe de graphite multifils pour une découpe précise

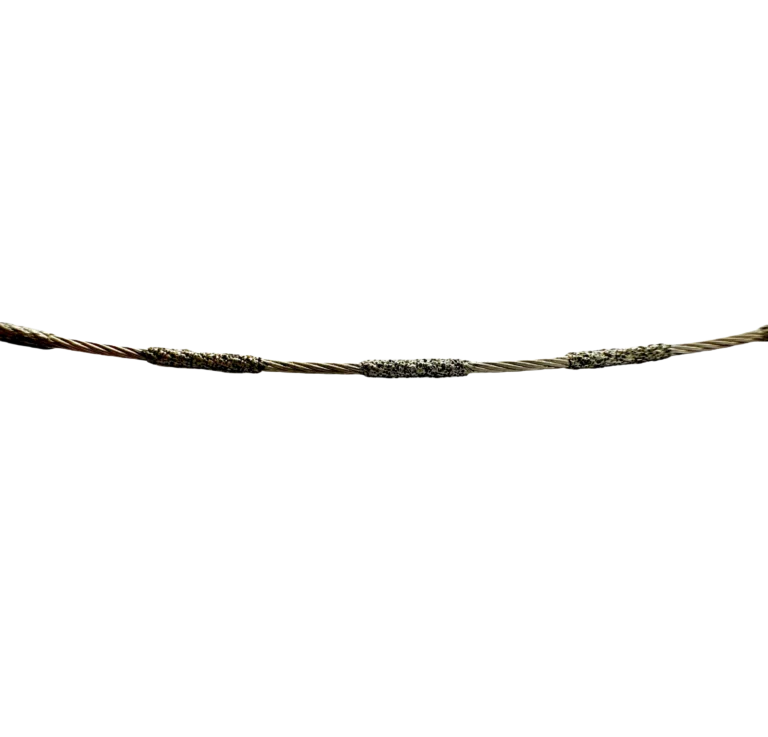

Carefully cutting graphite blocks is very important across many industries. A good Multi Wire Graphite Cutting Machine supplier helps businesses get strong, accurate machines. These machines make clean cuts and save material. Batteries, electronics, and machine parts are manufactured using them. Choosing the right supplier ensures that the machine performs well, lasts a long time, and has help when needed. A reliable Multi Wire Graphite Cutting Machine supplier gives machines that cut both small and large graphite blocks perfectly every time. We are a top-rated manufacturer and supplier of these cutting machines. Why Multi-Wire Graphite Cutting Machines Are Useful A Multi-Wire Graphite Cutter can cut multiple slices from a single block simultaneously. This saves a lot of time and speeds up production. It is very useful for cutting large graphite blocks because every slice comes out even. Multi-wire machines also reduce waste, which helps companies save money. They perform more