Le graphite est aujourd'hui utilisé dans de nombreuses usines. Il sert à fabriquer des moules, des électrodes et des pièces pour différentes machines. Cependant, la découpe du graphite n'est pas chose aisée. Le matériau peut se fissurer ou se casser si la machine n'est pas suffisamment puissante ou précise. machines de découpe de profil intérieur en graphite Pour résoudre ce problème, ils utilisent une technologie de pointe permettant de découper facilement les formes intérieures des matériaux en graphite.

Ces systèmes de découpe de graphite CNC L'accent est mis sur la vitesse, la précision et la fluidité des mouvements. Ces machines vous permettent de travailler plus rapidement et d'obtenir des résultats impeccables à chaque fois. Elles consomment également moins d'énergie et préservent la sécurité de votre espace de travail. Grâce à des entreprises comme Vimfun, pionnières en la matière, ces machines aident de nombreux secteurs à atteindre d'excellents résultats de découpe.

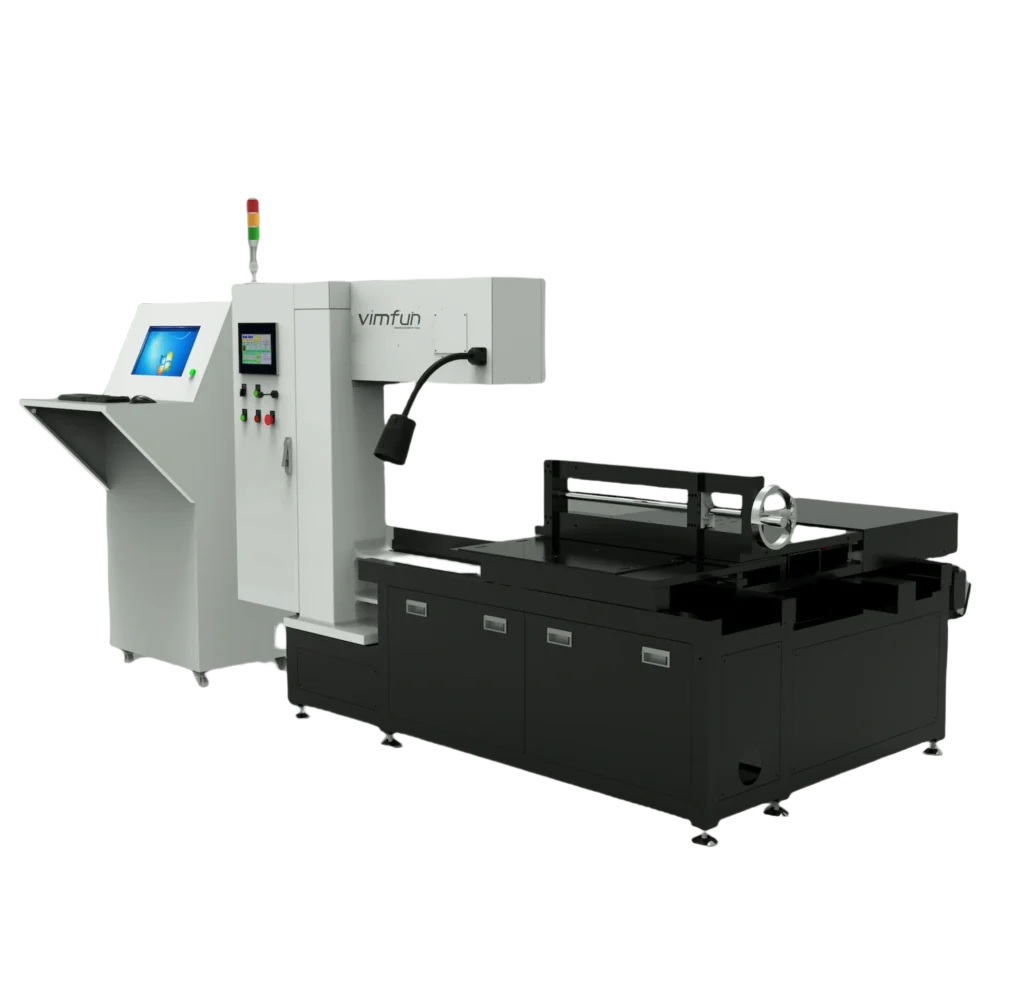

Machine de découpe de profils intérieurs en graphite de haute précision

Le SVI 80-80 est une machine de découpe au fil diamanté CNC puissante et précise, conçue pour façonner les parties intérieures des matériaux en graphite.

Elle permet de réaliser des trous, des fentes, des cadres internes et même des cavités complexes avec une précision et une netteté remarquables. Grâce à sa coupe sans éclats, elle préserve le matériau et réduit les déchets. Elle est ainsi idéale pour les entreprises fabriquant des moules en graphite, des électrodes pour électroérosion et des pièces en céramique technique.

Le fil diamanté coupeur de graphite Elle utilise un châssis vertical robuste qui assure une stabilité optimale lors de chaque coupe. Sa conception à portique solide et ses rails linéaires fluides permettent un déplacement précis de la table de travail. La SVI 80-80 est également équipée de la technologie du fil diamanté sans fin. Le fil se déplace à grande vitesse dans une seule direction, garantissant ainsi des coupes nettes et sans marques.

Technologie avancée de découpe de profils internes pour les matériaux en graphite

Moderne machines de découpe de profil intérieur en graphite Elle utilise une technologie de pointe qui simplifie et fluidifie la découpe. Le cœur de la machine comprend souvent un fil diamanté ou un outil de coupe de haute qualité, offrant une grande précision de mouvement. Cet outil découpe le graphite sans laisser d'arêtes vives.

Le présent usinage de la cavité interne en graphite Cette machine permet de suivre des formes internes très précises. Même les motifs complexes sont facilement reproduits. Elle réduit également la poussière, préservant ainsi la propreté de la zone de travail. Grâce à un processus de découpe stable, le graphite ne se fissure pas et ne s'écaille pas, garantissant des résultats nets et professionnels.

Machine à commande numérique intelligente pour un fonctionnement sans faille

Ces Machines de découpe de profils intérieurs en graphite Elle est équipée d'une machine à commande numérique (CNC). CNC signifie « Commande Numérique par Calculateur ». Cela signifie qu'un ordinateur contrôle les mouvements de découpe. Il vous suffit d'entrer votre motif de découpe dans la machine, qui le reproduira ensuite avec une grande précision.

Le Profilage de précision en graphite pour le façonnage de profils, réalisé avec précision. Ce logiciel facilite le travail des utilisateurs débutants comme des plus expérimentés. Il affiche des instructions claires à l'écran et permet de suivre la découpe en temps réel, pour une utilisation plus fluide et plus sûre. Son logiciel intelligent ajuste automatiquement la vitesse et la pression de découpe, garantissant ainsi des coupes nettes, même pour les formes les plus complexes.

Précision de découpe ultra-précise pour les géométries internes complexes

L'un des principaux avantages de ces machines réside dans leur précision de coupe. Elles sont conçues pour réaliser des profils intérieurs complexes, tels que des angles aigus, des parois fines ou des rainures profondes. De nombreux outils de coupe peinent à usiner de telles formes, mais les machines à profiler les profils intérieurs en graphite les maîtrisent parfaitement.

Le équipement de découpe de moules en graphite Les mouvements sont effectués par petits pas précis et contrôlés, ce qui permet à chaque découpe de suivre une trajectoire exacte. Même une petite erreur peut ruiner une pièce en graphite. Mais cette machine maintient la lame stable en permanence. Ainsi, chaque motif est net et correspond parfaitement au dessin.

Traitement à grande vitesse pour une productivité maximale

Les usines ont besoin de machines rapides. Ces machines de découpe offrent un traitement à grande vitesse. L'outil de coupe se déplace rapidement tout en restant stable, ce qui permet aux opérateurs de terminer leurs tâches plus rapidement sans compromettre la qualité.

La rapidité de la machine est un atout majeur pour les commandes importantes. Si une usine doit découper de nombreux blocs de graphite en une seule journée, la machine est parfaitement adaptée. Elle ne ralentit pas et ne surchauffe pas. La découpe rapide réduit également les temps d'attente, permettant aux opérateurs de passer plus rapidement aux étapes suivantes.

La découpe à grande vitesse n'endommage pas le graphite. La machine est conçue pour maintenir une pression faible et constante, ce qui contribue à protéger le matériau tout en assurant une cadence de travail élevée.

Structure stable et performances sans vibrations

Une machine stable permet des coupes précises. C'est pourquoi ces machines sont construites avec des châssis robustes. Le socle lourd assure l'immobilité de la machine pendant la coupe, réduisant ainsi les vibrations. Lorsqu'une machine vibre, la ligne de coupe risque de dévier. Ces machines, en revanche, évitent ce problème.

L'absence de vibrations permet à l'outil de coupe de suivre chaque courbe et chaque ligne avec précision. Elle protège également le fil ou la lame de coupe. Une machine stable garantit une durée de vie accrue et une meilleure performance de l'outil de coupe.

Cette structure stable est essentielle pour la découpe de profils intérieurs. Les découpes intérieures nécessitent une pénétration profonde dans le matériau. Si la machine vibre, la forme intérieure risque de se déformer. Avec une machine stable, vous avez la garantie de découpes nettes et précises.

Optimisé pour les électrodes en graphite, les moules et les composants industriels

Machines de découpe de profils intérieurs en graphite Ces machines sont performantes pour de nombreuses pièces en graphite, notamment les électrodes utilisées dans de nombreux secteurs industriels, ainsi que les moules en graphite, qui permettent de façonner différents matériaux. Elles sont également adaptées aux composants industriels en graphite.

Parce que le machine de découpe à électrode de graphite Capable de découper des formes intérieures complexes, cette machine aide les entreprises à créer des moules de haute précision. Ces moules nécessitent des bords parfaits et des parois lisses. Elle offre aux concepteurs la liberté d'explorer de nouvelles formes et de nouveaux motifs.

Les électrodes en graphite nécessitent également une découpe précise. Elles doivent s'ajuster parfaitement dans leurs machines. Une petite erreur peut compromettre l'ensemble du processus. La précision de ces machines de découpe permet d'éviter de tels problèmes.

Conception écoénergétique à faibles coûts d'exploitation

L'utilisation de machines de grande taille peut s'avérer coûteuse. Or, ces machines sont conçues pour une efficacité énergétique optimale. Elles consomment donc moins d'énergie tout en conservant une vitesse d'exécution élevée. Le moteur, le système de commande et l'outil de coupe sont conçus pour économiser l'énergie, ce qui permet aux entreprises de réduire leurs factures d'électricité.

Les faibles coûts d'exploitation s'expliquent également par des besoins de maintenance réduits. Grâce à sa stabilité et sa robustesse, la machine tombe rarement en panne. L'outil de coupe a également une durée de vie plus longue grâce à un mouvement fluide.

Sa conception écoénergétique est idéale pour les petites et grandes usines. Elle contribue à protéger l'environnement et à réduire les déchets.

Des solutions de découpe personnalisables pour répondre aux besoins de l'industrie

Les différents secteurs d'activité nécessitent des formes différentes. C'est pourquoi ces machines de découpe de profil intérieur en graphite Elle est personnalisable. Vous pouvez choisir la taille de la machine, la vitesse de coupe et le type de fil de coupe. Vous pouvez également sélectionner les fonctionnalités logicielles adaptées à votre activité.

Certaines usines nécessitent des découpes profondes. D'autres, des formes fines et étroites. Nombre d'entre elles ont besoin des deux. Une machine personnalisable permet d'adapter les réglages à chaque projet. Cette flexibilité facilite l'utilisation d'une même machine pour différentes tâches.

Dispositifs de sécurité garantissant un fonctionnement sûr et fiable

La sécurité est primordiale dans les usines. Ces machines de découpe intègrent de nombreux dispositifs de sécurité. Elles sont dotées de capots transparents qui protègent les opérateurs de la poussière et des pièces mobiles. Elles possèdent également des capteurs qui arrêtent la machine en cas de dysfonctionnement.

Le traitement de la géométrie interne du graphite Cela empêche l'outil de coupe de heurter une zone dangereuse. Le cadre stable réduit également les mouvements brusques, assurant ainsi un espace de travail sûr et serein.

Vimfun, expert en assistance, installation et service après-vente

Vimfun Cette entreprise est une référence dans le secteur des machines de découpe. Elle est reconnue pour ses machines de découpe au fil diamanté. Ces machines permettent de découper des matériaux durs et cassants avec une précision remarquable. Elles sont utilisées dans les industries des semi-conducteurs, de l'optoélectronique et des céramiques techniques.

Vimfun offre également un support complet pour machines de découpe de profil intérieur en graphite. Leur équipe assure l'installation de la machine, forme les employés à son utilisation et résout les problèmes éventuels. Ils offrent un service après-vente performant, garantissant ainsi une assistance permanente aux utilisateurs.

Ce soutien permet aux usines de fonctionner sans interruption. Il garantit également que chaque machine reste en excellent état pendant de nombreuses années.

En conclusion

Les machines professionnelles de découpe de profils intérieurs en graphite offrent des performances intelligentes, rapides et ultra-précises. Elles usinent facilement les formes intérieures complexes et contribuent à améliorer la productivité quotidienne des usines. Grâce à leur structure stable, leur vitesse élevée, leur commande numérique avancée et leurs dispositifs de sécurité robustes, ces machines garantissent d'excellents résultats.

Avec le soutien et l'expérience de Vimfun, Les industries peuvent ainsi bénéficier de machines fiables, durables, économes en énergie et garantissant des coupes parfaites à chaque utilisation. Pour une découpe de graphite de haute qualité, ces machines sont la solution idéale.

FAQ

Quels matériaux cette machine peut-elle découper ?

Il est principalement conçu pour le graphite et les matériaux similaires à base de carbone.

Le processus de découpe est-il précis ?

Il permet des découpes de haute précision adaptées aux profils intérieurs complexes.

La machine est-elle facile à utiliser ?

Oui, l'interface CNC intelligente rend l'utilisation simple et conviviale.

Permet-il de répondre aux exigences de découpe personnalisées ?

Oui, la machine peut être adaptée à différents besoins industriels.

Quel entretien nécessite-t-il ?

Uniquement le nettoyage de routine et les contrôles périodiques des composants.