Le graphite est un matériau tendre mais essentiel, utilisé aujourd'hui dans de nombreuses industries. On le retrouve notamment dans l'électronique, les batteries, les moules et les composants en carbone. La découpe manuelle du graphite est un processus difficile et risqué. Une machine de découpe automatique CNC simplifie et sécurise ce processus. Pilotée par ordinateur, elle suit des instructions précises, permettant ainsi aux usines de découper le graphite avec une précision constante. Avant d'acheter une machine de découpe automatique CNC pour graphite, de nombreux acheteurs se renseignent sur son prix. Ces machines permettent un gain de temps et une réduction des déchets, tout en garantissant des découpes nettes et régulières.

Importance de la commande numérique par ordinateur (CNC) dans la découpe du graphite

La commande numérique (CNC) est un atout majeur pour la découpe du graphite. CNC signifie que la machine fonctionne selon un programme informatique. L'opérateur définit la taille et la forme sur l'écran. La machine effectue ensuite la découpe avec précision. Ceci est particulièrement utile pour la découpe de blocs de carbone. Le graphite est fragile et peut se casser facilement si la pression exercée est incorrecte. La commande numérique maintient une pression constante, ce qui permet une découpe de graphite de haute précision. prix des machines de découpe automatique CNC pour graphite, La commande numérique par CNC est l'une des principales raisons de cette valeur plus élevée.

Caractéristiques principales des machines modernes de découpe du graphite

Les machines modernes de découpe du graphite possèdent de nombreux atouts. Leur construction robuste et stable leur permet de fonctionner pendant de longues heures. Nombre d'entre elles utilisent un système de découpe au fil diamanté, assurant une coupe lisse et uniforme du graphite. Un circuit continu de fil diamanté se déplace sans interruption, ce qui permet un gain de temps et une meilleure qualité de coupe. Ces machines peuvent également traiter des blocs de grande taille. Une machine de grande capacité est particulièrement utile pour la production industrielle. Toutes ces caractéristiques influent sur la qualité de la découpe.

Prix sur le marché des machines de découpe automatique de graphite CNC.

La technologie de découpe au fil diamanté expliquée

La technologie de découpe au fil diamanté est aujourd'hui très répandue. Une scie à fil CNC utilise un fil fin recouvert de diamant. Ce fil découpe le graphite avec une précision douce et régulière, sans créer de fissures ni d'aspérités. Une scie à fil diamanté sans fin permet une découpe continue, sans interruption. C'est un avantage considérable pour les machines à découper les blocs de graphite. Le fil a une durée de vie plus longue et nécessite moins de remplacement. Les machines équipées de ce système produisent du graphite avec un faible niveau de poussière. Cette technologie est l'une des principales raisons de son succès. prix d'une machine de découpe automatique CNC en graphite peut varier.

Facteurs influençant le prix des machines de découpe automatique de graphite CNC

De nombreux facteurs déterminent le prix final d'une machine. La taille de la machine est un facteur important. Une machine destinée à un usage intensif de découpe de graphite coûte plus cher. La précision de coupe influe également sur le prix. Les machines conçues pour le tranchage de graphite de haute précision sont plus onéreuses. Le niveau d'automatisation compte aussi. Les machines entièrement automatiques réduisent les coûts de main-d'œuvre. La qualité de fabrication et le service après-vente de la marque ont également un impact sur le prix. Lors de l'évaluation, prix d'une machine de découpe automatique CNC en graphite, Les acheteurs devraient prendre en compte les avantages à long terme, et pas seulement le coût initial.

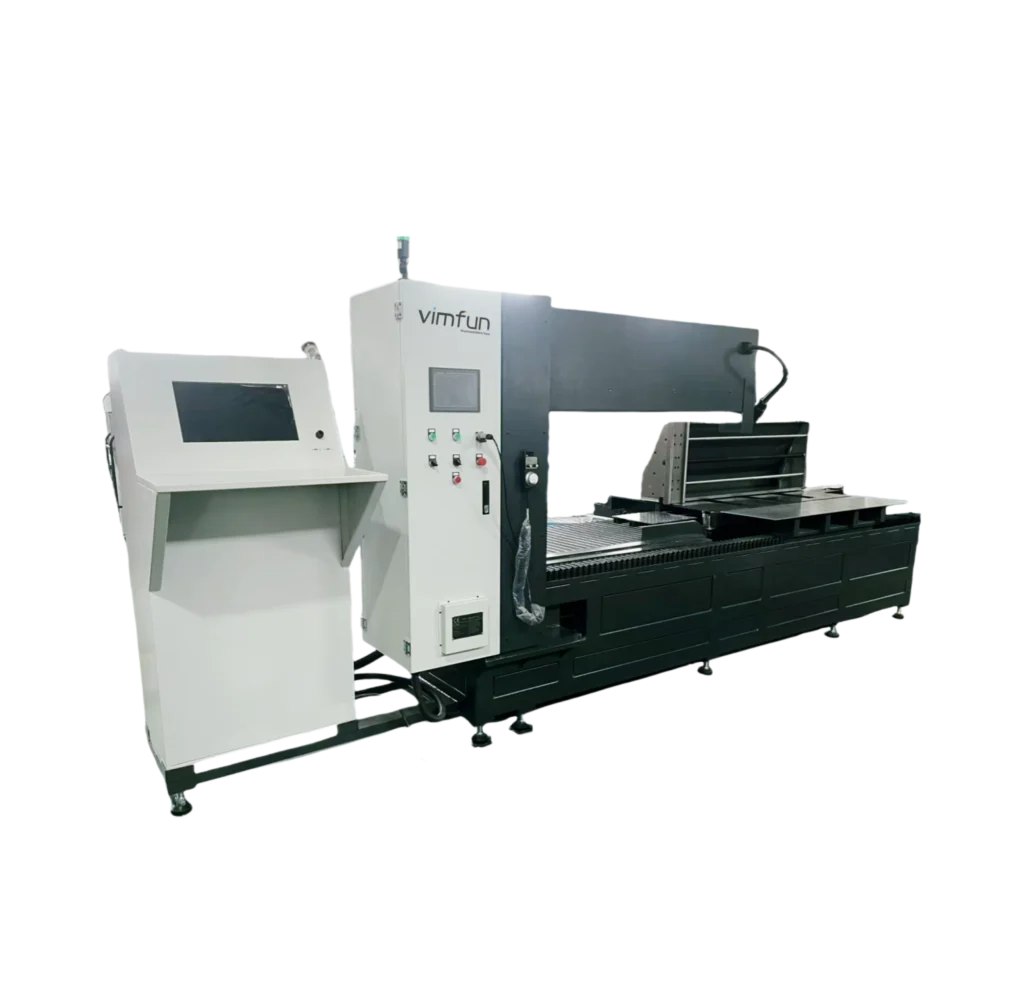

SVI 160-100 Machine automatique à découper le graphite à commande numérique

Le Machine de découpe automatique de graphite CNC SVI 160-100 Conçue pour un usage industriel, cette machine est idéale pour la découpe de blocs de carbone et de gros blocs de graphite. Elle utilise un fil diamanté à boucle continue pour une découpe nette et précise. La commande numérique par fil assure une grande facilité d'utilisation. Stable et performante, elle garantit des coupes nettes et précises. De plus, sa conception à faible émission de poussière contribue à maintenir un environnement de travail propre. Compte tenu de ses caractéristiques et de ses performances, le prix de cette machine de découpe automatique de graphite à commande numérique est tout à fait raisonnable.

Les principaux avantages comprennent

- Une structure solide pour un travail stable

- Scie à fil diamanté sans fin pour une coupe nette

- Système de commande CNC facile

Utilisations courantes des machines de découpe du graphite

Les machines de découpe du graphite sont utilisées dans de nombreux secteurs industriels. Elles servent notamment à découper les matériaux en graphite dans l'électronique et dans le secteur de l'énergie pour la fabrication de composants solaires et de batteries. Les fabricants de moules utilisent des systèmes de découpe de blocs de graphite pour les détails de précision. Les centres de recherche utilisent également des machines de découpe du graphite de haute précision. Ces machines contribuent à la production quotidienne de pièces propres et précises. Du fait de leur utilisation généralisée, la demande de machines de découpe du graphite est forte. prix des machines de découpe automatique CNC pour graphite elle se développe sur le marché mondial.

Avantages de la découpe au graphite à faible émission de poussière

La poussière de graphite peut engendrer des problèmes de santé et de propreté. La découpe du graphite à faible émission de poussière est au cœur des préoccupations des machines modernes. Celles-ci utilisent des espaces de coupe confinés et une vitesse adaptée, garantissant ainsi un air pur et la sécurité des opérateurs. Moins de poussière signifie également une durée de vie accrue des machines. Le temps de nettoyage est réduit et la productivité s'en trouve améliorée. De nombreux acheteurs privilégient les machines dotées d'un système de contrôle de la poussière performant, même si le prix d'une machine de découpe automatique de graphite à commande numérique est légèrement supérieur. En production, la propreté et la sécurité sont primordiales.

Solutions de découpe de graphite CNC simples et sûres

Vous souhaitez améliorer votre travail de découpe du graphite simplement et en toute sécurité ? Vimfun Vimfun est là pour vous aider. Nous fabriquons des machines CNC qui découpent le graphite avec précision. Robustes et faciles à utiliser, nos machines sont idéales pour vos tâches de production quotidiennes. Elles contribuent à réduire la poussière et le gaspillage de matériaux, pour un environnement de travail propre et sûr. Vimfun vous propose des prix compétitifs et un accompagnement personnalisé à chaque étape. Avec nos machines, vous avez la garantie d'une découpe nette et régulière. Visitez le site web de Vimfun dès aujourd'hui pour en savoir plus, obtenir des informations et choisir la machine de découpe de graphite CNC adaptée à la croissance de votre entreprise.

Ne vous contentez pas de vérifier prix d'une machine de découpe automatique CNC en graphite. De plus, il est essentiel de veiller à la qualité et à la précision de coupe de la machine. Une machine bien entretenue produit moins de déchets et est plus performante sur le long terme.

FAQ

- Qu'est-ce que la machine de découpe de graphite CNC SVI 160-100 ?

C'est une machine robuste et facile à utiliser pour la découpe de grands blocs de graphite avec peu de poussière.

- Qu'est-ce que la découpe au câble diamanté ?

La découpe au fil diamanté utilise un fil garni de diamants pour découper le graphite en douceur et sans fissures.

- Quels sont les avantages de la découpe au graphite à faible émission de poussière ?

Il permet de maintenir le lieu de travail propre et sûr et de réduire la maintenance des machines.

- Où ces machines sont-elles utilisées ?

Ils sont utilisés dans l'électronique, l'énergie, la fabrication de moules et la recherche pour la découpe de blocs de graphite.