Резка графита является ключевым процессом в приложениях, связанных с электродами для электроэрозионной обработки, высокотемпературными пресс-формами и системами хранения энергии. Когда дело доходит до графитовые блоки высокой плотностиНо задача резки становится еще более сложной из-за повышенной хрупкости материала, его термочувствительности и возможности растрескивания поверхности. Чтобы сохранить точность размеров, качество поверхности и эффективность производства, производители должны применять специальные стратегии, предназначенные для плотных графитовых материалов.

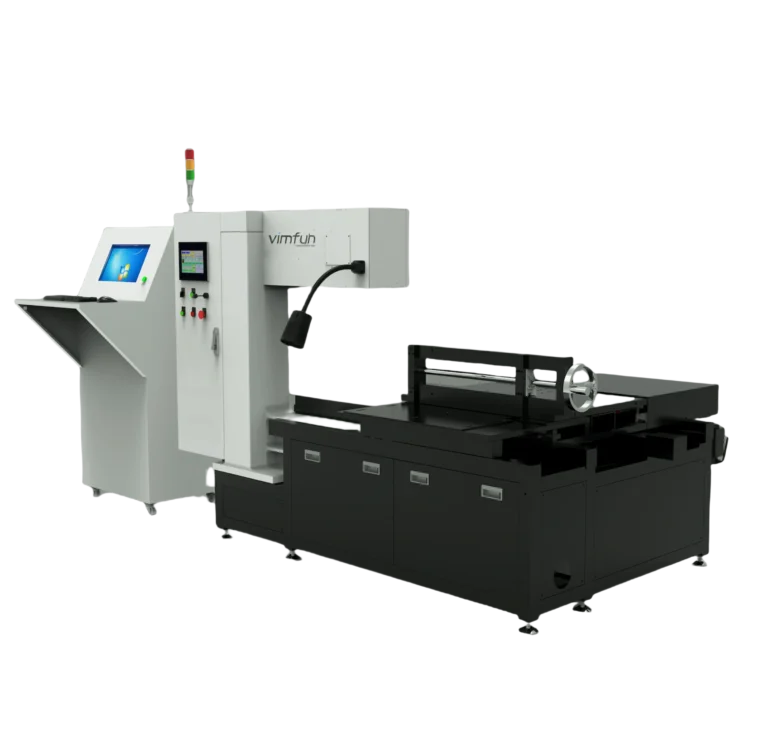

В этой статье рассматриваются лучшие практики в обработка алмазной проволочной пилойНастройка, выбор инструмента и контроль окружающей среды при работе с графитом высокой плотности

1. Понять характеристики графита высокой плотности

Прежде чем выбрать подходящий метод резки, важно понять, как высокоплотный графит отличается от стандартных марок.

- Высокая прочность на сжатие и пониженная пористость делают его более подходящим для конструкционных и высокопроизводительных применений.

- Однако те же свойства приводят к тому, что пониженная вязкость разрушениячто повышает риск сколов кромок и дефектов поверхности при обработке.

Эти характеристики требуют применения прецизионных инструментов и хорошо контролируемых условий резки, чтобы избежать появления микротрещин и сохранить целостность материала.

2. Использование алмазной проволочной пилы для обеспечения точности и качества поверхности

Среди имеющихся методов можно выделить алмазная проволочная пила является оптимальным выбором для резка графитовых блоковособенно при работе с плотными и хрупкими материалами.

Преимущества включают:

- Минимальная потеря пропила: Алмазные проволочные пилы создают узкий разрез, сохраняя больше материала и уменьшая образование пыли.

- Низкое механическое напряжение: Процесс резки основан на истирании, а не на сдвиге, что сводит к минимуму повреждение поверхности.

- Превосходная обработка поверхности: Резка проволокой оставляет гладкую поверхность, что снижает необходимость вторичной шлифовки или полировки.

В отличие от этого, обычные ленточные пилы или дисковые фрезы могут создавать вибрацию или локальный нагрев, что повышает риск расслоения или растрескивания графита высокой плотности.

3. Оптимизация параметров резки с учетом плотности и размера зерен

Для достижения стабильных результатов очень важно откалибровать параметры резки в соответствии с конкретной маркой графита:

- Скорость движения проволоки: Обычно 800-1500 м/мин для графита высокой плотности. Более низкая скорость может привести к вытягиванию материала, а чрезмерная - к перегреву зоны реза.

- Скорость подачи: Должен быть тщательно сбалансирован. Слишком быстрая подача может привести к появлению трещин, а слишком медленная снижает производительность.

- Охлаждение/смазка: Используйте чистую фильтрованную воду (если возможна мокрая резка) для охлаждения проволоки и уменьшения количества пыли. Для сухой резки установите эффективную вакуумную систему.

Регулировка этих значений в соответствии с размером, ориентацией и зернистой структурой блоков является ключевым фактором для поддержания стабильности в разных партиях.

4. Выберите правильную спецификацию алмазной проволоки

Не все алмазные проволоки созданы одинаковыми. Идеальная спецификация для резка плотного графита включает в себя:

- Меньший размер алмазной крошки (например, D60-D80) для уменьшения шероховатости поверхности.

- Средняя и высокая концентрация алмазов для стабильной резки без сильного натяжения проволоки.

- Гальванические или смоляные типы проводовВ зависимости от того, что для вас важнее - долговечность или качество поверхности.

Проволока на основе смолы особенно полезна при резке очень хрупкого или мелкозернистого графита, поскольку она уменьшает образование микротрещин.

5. Обеспечение устойчивости машины и контроль натяжения

Настройка станка напрямую влияет на качество резки. Для достижения наилучших результатов:

- Поддерживать последовательность натяжение проволоки на протяжении всего процесса резки. Настоятельно рекомендуется использовать автоматические системы натяжения.

- Избегайте вибрация или биение проволоки, что может произойти из-за перекоса шкива или износа подшипников.

- Используйте графитовый пылезащитный кожух или герметичной камере для уменьшения содержания частиц в воздухе и защиты оператора и электроники.

Эти методы не только улучшают качество резки, но и продлевают срок службы как проволоки, так и оборудования.

6. Внедрить предварительную подготовку материала

Чтобы уменьшить внутреннее напряжение и избежать сколов краев, обратите внимание на следующее:

- В более холодных помещениях предварительно слегка подогрейте блоки, чтобы уменьшить тепловой удар.

- Перед резкой удалите пыль с поверхности с помощью продувки сжатым воздухом или пылесоса.

- Проверьте наличие существующих микротрещин, которые могут распространиться во время обработки, если их не устранить.

Это особенно важно в тех случаях, когда требуются жесткие допуски или склеивание поверхностей.

7. Резюме: основные выводы для резки плотных графитовых блоков

Резка графитовые блоки высокой плотности требует точного баланса возможностей станка, выбора инструмента и контроля резания. Лучшие практики включают:

| Практика | Рекомендация |

|---|---|

| Метод резки | Алмазная проволочная пила для низкого напряжения и высокой точности |

| Размер зернистости проволоки | D60-D80 (мелкая зернистость) |

| Скорость подачи | Умеренная, с устойчивым контролем |

| Система охлаждения | Водяное охлаждение или пылесос (в зависимости от комплектации) |

| Предварительно вырезанные чеки | Очистите поверхности, проверьте трещины, стабилизируйте температуру |

| Характеристики машины | Стабильное натяжение проволоки, система контроля пыли, минимальная вибрация |

Интегрируя эти методы, производители могут повысить производительность, уменьшить износ инструмента и добиться лучшего контроля размеров при обработке плотных графитовых материалов.