If your job includes cutting shapes that are hard or have many sharp turns and lines, this Graphite Inner Profile Cut Machine is the perfect tool to help you. It can quickly cut inside curves, small holes, and narrow parts. It is made simple to use, so you can focus more on your work and less on learning the tool. This cutter saves you a lot of time and gives you better-looking results by helping you do hard and tricky cuts efficiently.

Works of a Graphite Inner Profile Cut Machine

A CNC graphite inner cut machine is a tool that uses a computer to cut shapes in graphite. CNC stands for Computer Numerical Control. That means you give the machine a shape design using a computer. The machine then follows the design and cuts the shape precisely. It is the same shape every time, with no mistakes. It is excellent for making tools, molds, or parts. It is easy to learn and use even if you are new to machines.

Try an Inner Profile Cutter for Graphite Blocks

A Graphite Inner Profile Cut Machine for graphite is excellent for cutting deep inside the block. It can go into places where hands and big tools cannot reach. This cutter is easy to use and makes cuts that look neat. You should try it because:

- It saves a lot of time

- The shapes come out very clean

- You can use it on blocks of all sizes

- It is easy to learn, even for beginners

- It stops mistakes and saves graphite

- It helps you make strong and smooth molds

How Graphite Inner Shape Cutting Machines Help

It can be tricky with standard tools when you need to cut inside the graphite. A Graphite Inner Profile Cut Machine is built just for that job. It goes deep inside and still keeps the lines smooth and sharp. You can use this machine to:

- Make detailed graphite molds

- Cut small and exact parts

- Shape heat tools or power parts

- Create clean blocks for machines

Pick the Right Graphite Block Profile Cutter

Picking the right Graphite Inner Profile Cut Machine is very important. A graphite block profile cutter can work with all kinds of block sizes. It cuts both outside and inside edges with care. The shapes come out neat every time. These cutters are great for:

- Large factories and tool shops

- Small local businesses

- People who make molds and sell parts

- Labs that need special graphite tools

Best Machines for Cutting Graphite Fast and Neatly

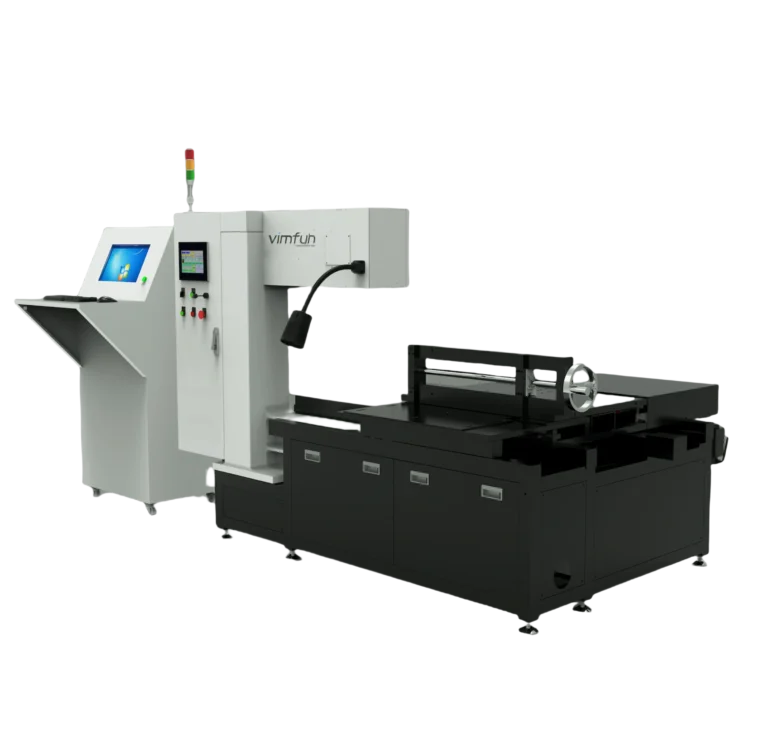

Here are three top Graphite Inner Profile Cut Machines that work great with graphite blocks. They are strong, easy to use, and always give clean results.

SVI 160-100: A Big and Strong Machine for Large Jobs

Các SVI 160-100 Graphite Inner Profile Cut Machine is the best tool for cutting big graphite blocks. It can cut wide and deep shapes. This machine works for many hours without stopping. It is excellent for large shops or mold makers.

Main Info:

- Work space: 160mm x 100mm

- Best use: Cutting large graphite pieces

- User-friendly: Simple controls and fast learning

Great for:

- Big machine molds

- Large shape cutting

- Shops that need to cut often

SVI 60-60: A Small and Fast Machine for Tiny Jobs

Các SVI 60-60 Graphite Inner Profile Cut Machine is small but mighty. It is suitable for small jobs and fast work. You can put it almost anywhere in your shop. It is perfect for small parts and easy cuts.

Main Info:

- Work space: 60mm x 60mm

- Best use: Quick and small cuts

- User-friendly: Quick setup and easy to move

Great for:

- Tiny mold parts

- Short and fast jobs

- Home shops or small labs

SVI 80-80: The Best Machine for Everyday Jobs

Các SVI 80-80 Graphite Inner Profile Cut Machine is just the right size. It is not too big or too small. You can use it for many different jobs. It cuts fast and keeps shapes looking great.

Main Info:

- Work space: 80mm x 80mm

- Best use: Every day, cutting work

- User-friendly: Runs long hours with clean cuts

Great for:

- Mold and tool shops

- Custom parts

- Any kind of job

CNC Machines Make Graphite Profile Cutting Easy

A CNC machine for graphite profiles makes cutting smooth and straightforward. It follows your design every time. You will not make mistakes. These machines are loved by shops because they work fast and save graphite. They are suitable for making many parts in a short time.

- EDM Cutting: for Smooth & Clean Shapes

EDM stands for Electrical Discharge Machining. A graphite profile EDM cutting machine uses tiny sparks to cut the graphite. It does not leave rough edges. The shapes come out very smooth and clean. It is best when your work looks perfect.

- Cutting with a Precision Graphite Cutting Machine

A precision graphite cutting machine helps you get exact and perfect shapes. It stops mistakes and leaves no rough lines. This tool is excellent for strong tools, clean molds, and detailed shapes. It also helps protect the graphite from breaking.

- Use a Graphite Internal Cutting System for Inside Cuts

Do you need to cut inside a graphite block? A graphite internal cutting system is the right tool. It cuts deep shapes and does not hurt the rest of the block. You can use it for curves, holes, and shapes that are hard to reach.

- Right Molds with a Graphite Mold Inner Cutter

Molds need to be cut the right way. A graphite mold inner cutter makes sure the lines are sharp and clean. It helps you make perfect molds that work well. This tool is great for shops that need to make many good molds from graphite.

Vimfun Is the Best Place to Get These Machines

If you want strong and easy-to-use machines, check out Vimfun. They sell high-quality CNC graphite machines. Their tools last long and are made to do the job right every time.

Why People Choose Vimfun:

- Many machines to pick from

- Long-lasting tools

- Simple to learn and use

- Friendly and helpful team

- Fast and safe delivery

If you want to make fast, clean, and easy cuts in graphite, try a Graphite Inner Profile Cut Machine. Use Graphite Inner Profile Cut Machines like SVI 160-100, SVI 60-60, or SVI 80-80 to simplify your job. Always choose Vimfun if you want machines that work great and last!

FAQs

What can these machines cut?

They can cut graphite blocks into tools, parts, and molds.

Can they cut deep shapes?

Yes, they cut deep and keep the edges clean.

Are they hard to use?

No. They are easy to control and learn fast.

Which machine should I choose?

Use SVI 60-60 for small parts, SVI 80-80 for most jobs, and SVI 160-100 for big blocks.

Where can I buy one?

Go to Vimfun and pick the best machine for your job.