Energiesparende Graphitschneidemaschinen verbrauchen deutlich weniger Strom und produzieren dabei minimalen Abfall. Diese modernen Maschinen schneiden Blöcke, Platten, Stäbe und Plättchen mit glatten, gleichmäßigen und sauberen Schnittkanten. Jeder Schnitt erfolgt präzise und sauber, sodass sowohl kleine als auch große Projekte problemlos bewältigt werden können. Dank ihrer robusten Bauweise sind sie langlebig und bieten Betrieben und Werkstätten über viele Jahre hinweg einen echten Mehrwert.

Diese Schneidemaschinen ermöglichen es Arbeitern, mehr Aufgaben in kürzerer Zeit zu erledigen und dabei sicher zu arbeiten und den Arbeitsbereich sauber zu halten. Die Wahl der richtigen Schneidemaschine spart Zeit, reduziert Abfall, senkt Kosten und sorgt für einwandfreie Schnittergebnisse. Viele moderne Fabriken suchen heute nach der besten Graphitschneidemaschine für die jeweilige Branche: benutzerfreundlich, sicher im Betrieb, kostengünstig und robust für den Dauereinsatz.

Warum Energiesparen für Graphittrennmaschinen unerlässlich ist

Alte Schneidemaschinen verbrauchen oft zu viel Energie und erzeugen zu viel Abfall. Das treibt die Kosten in die Höhe und schadet der Umwelt. Neue Graphitschneider Sie sind so konstruiert, dass sie mit weniger Energieaufwand schneiden und die Ausbeute jedes Graphitblocks maximieren. Ein gutes Präzisions-Graphitschneidwerkzeug leistet zweierlei: Es reduziert Abfall und spart Kosten. Zudem trägt es zur Verringerung des CO₂-Fußabdrucks eines Werks bei. Durch geringeren Energieverbrauch und weniger Abfall kann ein Werk Kosten senken, Platz sparen und den gesamten Arbeitsbereich sicherer und sauberer gestalten. Viele Betriebe setzen daher aus Kostengründen, zur Erreichung von Umweltzielen und für ein besseres Arbeitsumfeld auf energiesparende Werkzeuge.

Vorteile von CNC-Graphitfräsern

- Schnelle Schnitte, die den Arbeitsablauf ohne lange Wartezeiten gewährleisten.

- Weniger Abfall, sodass jeder Block, jede Stange oder jede Scheibe häufiger verwendet werden kann.

- Die Kanten werden glatt und glänzend, sodass weniger Polieren nötig ist.

- Einfache Einrichtung, die neue Mitarbeiter schnell erlernen können.

- Robuste und langlebige Bauteile, die die Reparaturkosten senken.

- Schneidet mühelos Scheiben, Stäbe, Platten oder Elektroden.

- Sicheres Design, das die Sicherheit der Arbeiter beim Schneiden gewährleistet.

- Kompakte Bauweise, die in überfüllten Geschäften Platz spart.

- Hilft dabei, Umweltauflagen zu erfüllen, indem Abfall und Ausschuss reduziert werden.

- Überzeugende Ergebnisse, die bei jedem Schnitt gleich bleiben.

Spitzenleistung bei energieeffizienten Graphittrennscheiben

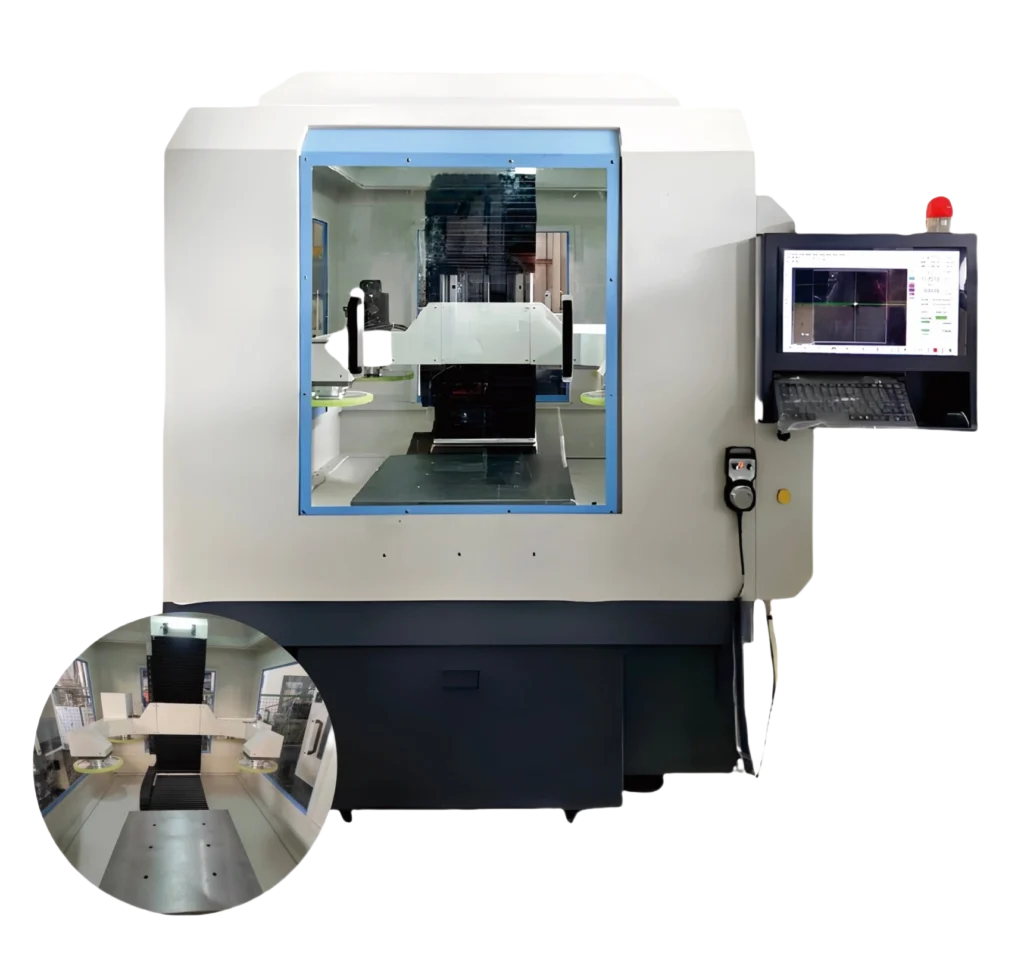

SH 60-60 Horizontale Graphitschneidemaschine

Die SH 60-60 Die SH 60-60 ist ein leistungsstarkes Werkzeug für große Projekte, bei denen Geschwindigkeit und Kraft entscheidend sind. Sie schneidet selbst große Blöcke mühelos und schnell. Damit ist sie eine der besten Optionen für Betriebe, die eine Graphitblockschneidanlage benötigen, die Zeit und Kosten spart. Dank ihrer robusten Bauweise ist sie auch für unerfahrene Mitarbeiter leicht zu bedienen. Ihr langlebiger Rahmen sorgt für geringe Abfallmenge und minimalen Wartungsaufwand. Wenn Sie eine Graphitschneidemaschine für einen mittelständischen oder großen Betrieb suchen, ist die SH 60-60 eine ausgezeichnete Wahl. Sie arbeitet über viele Stunden zuverlässig und präzise und gewährleistet dabei saubere, präzise Schnitte und Sicherheit am Arbeitsplatz.

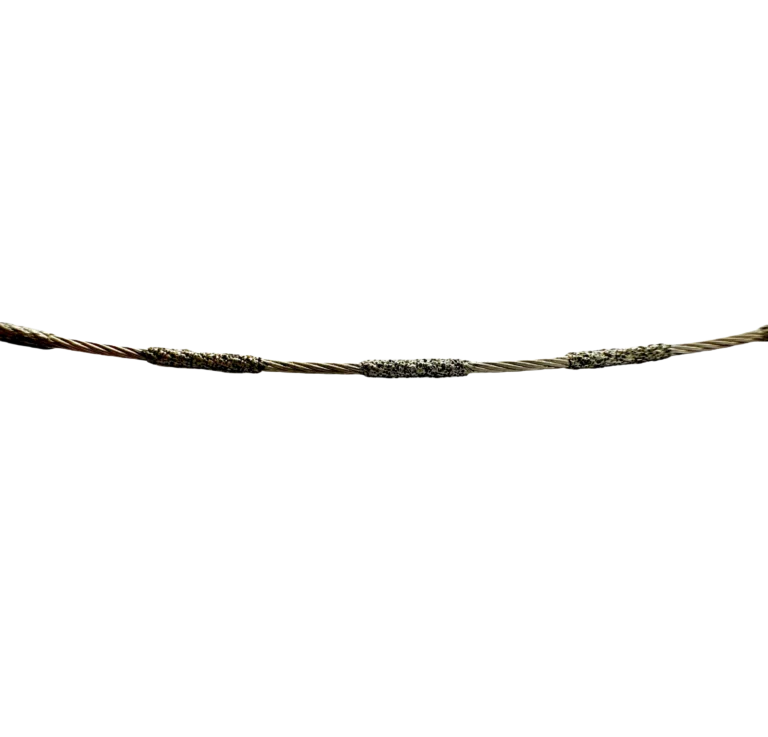

Die SV 240-40 CNC-Diamantdrahtschneidmaschine

Die SV 240-40 Diese Graphit-Schneidemaschine ist für dünne, präzise Schnitte konzipiert, die scharf und exakt sein müssen. Sie verwendet einen Diamantdraht für besonders glatte Schnittkanten und minimalen Materialverlust. Wenn Sie einen zuverlässigen Lieferanten für Graphit-Schneidemaschinen suchen, ist dies die beste Wahl. Sie eignet sich optimal für dünne Platten und Scheiben, bei denen jeder Millimeter zählt. Selbst bei hohen Drehzahlen liefert sie gleichmäßige und saubere Ergebnisse. Für jede Werkstatt, die ein Hochgeschwindigkeits-Graphit-Schneidewerkzeug benötigt, ist diese Maschine eine zuverlässige Lösung. Sie ist zudem leicht zu reinigen, sicher in der Anwendung und einfach zu warten. Sie vereint Geschwindigkeit, Präzision und gleichmäßiges Arbeiten.

SV 60-60 Vertikale Graphitschneidemaschine

Die SV 60-60 Diese große, robuste Maschine ist ideal für anspruchsvolle Aufgaben wie das Schneiden dicker Stangen und Blöcke. Sie schneidet Stangen, Blöcke und Platten mühelos. Viele Anwender bezeichnen sie als die beste Graphitschneidemaschine für die Industrie, da sie Jahr für Jahr gleichbleibend gute Ergebnisse liefert. Trotz ihrer Größe benötigt sie nur wenig Stellfläche und lässt sich daher problemlos in Produktionshallen aufstellen. Sie kann sowohl als industrielle Graphitplattenschneidemaschine als auch als Graphitstangenschneidemaschine eingesetzt werden und bietet somit mehrere Funktionen in einem einzigen Werkzeug. Betriebe, die ein Gerät für vielfältige Aufgaben suchen, sparen mit diesem Modell oft Geld.

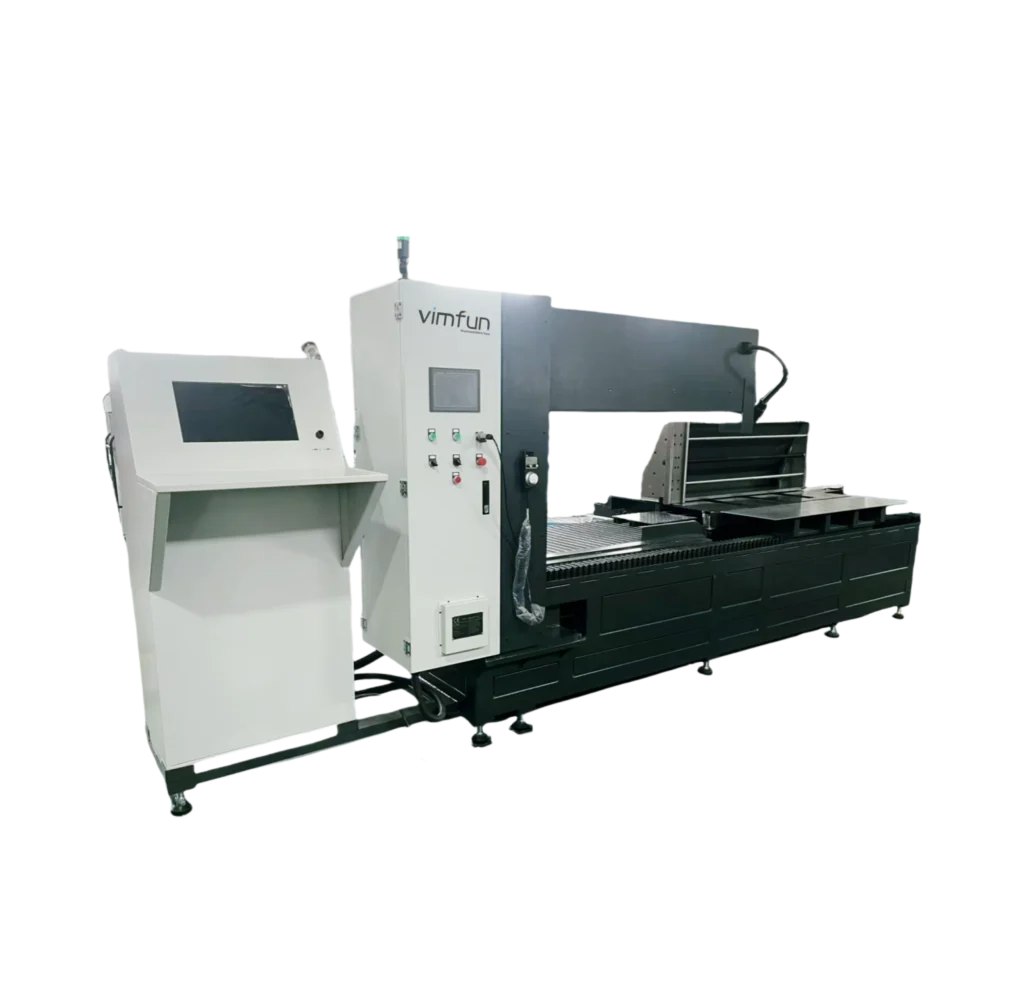

SVI 160-100 Automatische CNC-Graphitschneidemaschine

Die SVI 160-100 Diese vollautomatische CNC-Schneidemaschine ist für den Dauereinsatz konzipiert. Sie arbeitet stundenlang mit hoher Geschwindigkeit und benötigt nur wenig Personal. Sie ist die ideale Lösung, wenn Sie eine Graphit-Elektrodenschneidmaschine benötigen, die Tag und Nacht ohne Unterbrechungen arbeitet. Jeder Schnitt ist gleichmäßig, sauber und von einheitlicher Größe. Diese Maschine zählt zu den zuverlässigsten Präzisions-Graphitschneidmaschinen für große Betriebe, die rund um die Uhr ohne Qualitätseinbußen arbeiten müssen. Sie spart Arbeitszeit, senkt die Kosten und gewährleistet konstant hohe Ergebnisse – Tag für Tag.

Wie man den richtigen Gemüsehobel auswählt

- Prüfen Sie die Größe der Blöcke, Stäbe oder Scheiben, die zugeschnitten werden müssen.

- Überlegen Sie sich, welche Geschwindigkeit, Größe und Art des Schnitts Sie am meisten benötigen.

- Schauen Sie sich den Energieverbrauch und die Abfallmenge der Maschine an.

- Wählen Sie je nach Bedarf Ihrer Pflanze zwischen automatischem und manuellem Modus.

- Vergleichen Sie die Preise für Graphitschneidemaschinen, bevor Sie kaufen.

- Berücksichtigen Sie Platzbedarf, Qualifikation der Arbeitskräfte und langfristige Kosten.

- Stellen Sie sicher, dass die Schneidemaschine Ihren wichtigsten Arbeitszielen entspricht.

- Erkundigen Sie sich beim Verkäufer nach Kundendienstleistungen und Ersatzteilen.

Vergleichen Sie Graphittrennscheiben, um die beste Übereinstimmung zu finden

| Modell | Typ | Am besten für | Hauptmerkmal |

| SH 60-60 | Horizontal | Große Blöcke, schwere Arbeit | Gleichmäßige Geschwindigkeit, geringer Abfall |

| SV 240-40 | CNC-Diamant | Wafer, dünne Blätter | Feine Schnitte, saubere Kanten |

| SV 60-60 | Vertikal | Stäbe, Platten, große Blöcke | Kompakt, leistungsstark |

| SVI 160-100 | CNC-Automatik | Elektroden, lange Arbeiten | Automatischer Ablauf, schnell, geringer Arbeitsaufwand |

Vimpun: Führende Marke für den Kauf von Graphitschneidern

Vimfun Vimfun ist ein renommierter Lieferant von Graphit-Wafer-Schneidemaschinen mit langjähriger Erfahrung. Das Unternehmen bietet Käufern eine große Auswahl an Maschinentypen sowie umfassenden Support. Die Graphit-Schneidemaschinen sind robust gebaut, preisgünstig und langlebig. Die Modelle SH 60-60, SV 240-40, SV 60-60 und SVI 160-100 mit detaillierten Spezifikationen finden Sie auf der Website. Wenn Sie eine Graphit-Schneidemaschine online kaufen möchten, ist Vimfun eine sichere Wahl. Das Unternehmen bietet außerdem Ersatzteile, Reparaturhilfe und umfassende Betreuung, um einen reibungslosen Produktionsablauf zu gewährleisten.

Graphitschneider Diese Schneidemaschinen schneiden glatt und sauber und ermöglichen so sichere, schnelle und effiziente Arbeitsergebnisse. Sie helfen, Zeit zu sparen, Abfall zu reduzieren und Kosten zu senken. Jeder Schnitt sieht sauber aus, und jedes Ergebnis ist besser. Sie ermöglichen es Ihnen, mehr Arbeit in kürzerer Zeit zu erledigen und gleichzeitig die Umwelt durch geringeren Energieverbrauch zu schonen. Mit diesen Schneidemaschinen wird Ihre Arbeit einfacher, günstiger, schneller und besser für die Umwelt.

Energiesparend Graphitschneider Sie helfen, Kosten zu senken, die Arbeitsgeschwindigkeit zu erhöhen und sauberere Schnitte zu erzielen. Sie sind unverzichtbare Werkzeuge für Betriebe, die höhere Erträge und weniger Abfall anstreben. Benötigen Sie eine Graphitelektroden-Schneidemaschine oder eine Graphitstab-Schneidemaschine? Vimfun bietet robuste, sichere und preisgünstige Geräte für vielfältige Anforderungen. Sie zeichnen sich durch Langlebigkeit, sichere Anwendung und zuverlässige Ergebnisse aus. Besuchen Sie noch heute Vimfun, um alle Schneidemaschinenmodelle zu entdecken und das passende für Ihren Betrieb auszuwählen.

FAQs

- Was kostet eine Graphitschneidemaschine im Durchschnitt?

Der Preis variiert je nach Größe, Typ und Ausführung. CNC-Werkzeuge sind in der Anschaffung teurer, sparen aber langfristig Geld.

- Welcher Graphitschneider eignet sich am besten für den industriellen Einsatz?

Viele sagen, die SV 60-60 und die SVI 160-100 seien die beste Wahl für große und stark frequentierte Anlagen.

- Kann eine Schneidemaschine sowohl Blöcke als auch Stangen schneiden?

Ja. Mit der SV 60-60 lassen sich Blöcke, Stangen und Platten problemlos schneiden.

- Wo kann ich einen Graphitschneider online kaufen?

Sie können ein Gerät mit Komplettservice über die Website von Vimfun bestellen.

- Was macht ein Hochgeschwindigkeits-Graphitschneidwerkzeug so besonders?

Es arbeitet schnell, schneidet sauber und reduziert Ausschuss und Abfall.

- Benötigen Graphit-Elektrodenschneidmaschinen besonders qualifiziertes Personal?

Nein, sie sind so konzipiert, dass sie einfach zu bedienen und leicht zu erlernen sind.

- Wie lange ist die Lebensdauer eines Präzisions-Graphitschneidwerkzeugs?

Bei guter Pflege und Wartung kann es viele Jahre lang zuverlässig genutzt werden.

- Kann ein industrieller Graphitplattenschneider auch für dünne Scheiben verwendet werden?

Ja. Einige Geräte, wie das SV 240-40, sind speziell für Wafer entwickelt und liefern die besten Ergebnisse.