In diesem Artikel gehen wir der Frage nach, warum Schneiden von PU-Isolierblöcken Genauigkeit und Sorgfalt erfordert, ist die Probleme mit herkömmlichen Schneidmethodenund wie Diamantdrahtschneidetechnik bietet eine sauberere, effizientere Lösung für die Verarbeitung von Polyurethan-Dämmstoffblöcken.

Isolierblöcke aus Polyurethan (PU) sind ein Eckpfeiler des modernen energieeffizienten Bauens. Aufgrund ihrer ausgezeichneten Wärmebeständigkeit, geringen Wasseraufnahme und strukturellen Stabilität werden PU-Materialien häufig für vorgefertigte Wandpaneele, Kühlhäuser und Gebäudefassaden verwendet. Allerdings sind ihre einzigartige Materialeigenschaften machen das Schneiden zu einer technischen Herausforderung-besonders wenn Präzision, Sauberkeit und Wiederholbarkeit erforderlich sind.

Abschnitt 1: Warum PU-Dämmblöcke nur schwer zu schneiden sind

PU-Blöcke - ob hart oder halbstarr - kombinieren einen leichten Schaumstoffkern mit einer zerbrechlichen Oberflächenstruktur. Das Material ist zwar nicht so hart wie Keramik oder Metall, aber seine geringe Dichte und elastische Verformung besondere Herausforderungen mit sich bringen:

- Kanteneinbruch oder Riss: Herkömmliche mechanische Klingen komprimieren oft die Schaumstoffstruktur, was zu ungleichmäßigen Schnitten und bröckeligen Kanten führt.

- Maßliche Ungenauigkeit: PU-Blöcke werden häufig in ineinandergreifenden Wandsystemen verwendet, die eine exakte Dimensionierung. Herkömmliche Schneidverfahren haben Schwierigkeiten, die Toleranz einzuhalten.

- Oberflächenstaub und Schutt: Hochgeschwindigkeits-Sägeblätter oder heiße Drähte können PU-Pulver und thermische Zersetzungdie schwer zu entfernen sind und die nachfolgende Laminierung oder Versiegelung beeinträchtigen.

Abschnitt 2: Die Grenzen traditioneller Schneidetechnologien

Viele Hersteller verlassen sich auf Bandsägen, hin- und hergehende Sägeblätter oder heiße Drähte um PU-Blöcke zu verarbeiten. Diese Tools sind zwar zugänglich, haben aber oft Probleme:

- Schlechte Oberflächenqualität

- Langsame Vorschubgeschwindigkeiten für dicke Blöcke

- Hohe Staubbelastung und Notwendigkeit von Absauganlagen

In der Massenproduktion führen diese Nachteile dazu, dass verstärkte Nacharbeit, Materialabfallund Ausfallzeitund treiben die Produktionskosten in die Höhe.

Abschnitt 3: Wie das Schneiden mit Diamantdraht das Problem löst

A Diamantdrahtsägebesonders in Endloskonfigurationbietet eine präzise Alternative für das Schneiden von PU-Isolierungen. Obwohl sie oft für spröde oder harte Materialien verwendet werden, ist die gleiche Abrasiver und stoßfreier Schneidmechanismus ist gut geeignet für weiche, aber empfindliche Materialien wie PU.

✅ Saubere, reißfreie Schnitte

- Die feinen Diamantpartikel schleifen sich durch das Material, ohne es zu verformen oder zusammenzubrechen.

- Dies gewährleistet scharfe, eckige Kantenideal für modulare Isolieranwendungen.

✅ Konsistente Abmessungen

- CNC-gesteuerte Diamantseilsägen ermöglichen programmierbarer Dicken- und Formschnitt mit einer Toleranz von <0,2 mm - perfekt für eine gleichmäßige Wandplattenproduktion.

✅ Staubarm und nicht brennend

- Der Schneidevorgang erzeugt praktisch keine WärmeDadurch wird der thermische Abbau oder das Schmelzen, das bei Heißdrahtsystemen auftritt, vermieden.

- Der Staub ist minimal und besteht zumeist aus großen Partikeln, die durch Absaugen leicht zu erfassen sind.

✅ Hoher Durchsatz bei großen Blöcken

- Endlos-Diamantseilsägen bieten DauerbetriebSchneiden von ganzen PU-Platten oder Ziegeln in Einzelbewegungen, um die Geschwindigkeit zu erhöhen, ohne die Qualität zu beeinträchtigen.

Abschnitt 4: Anwendungsfälle bei der Herstellung von Baumaterialien

Wir haben mit mehreren Isoliermaterialherstellern zusammengearbeitet, die auf das Schneiden mit Diamantdraht umgestiegen sind, um die Qualität zu verbessern und die Ausschussrate zu senken. Einige bemerkenswerte Anwendungen sind:

- Schneiden großer PU-Blöcke in Wandplatten mit gleichmäßiger Dicke

- Vorbereiten von PU-Kernen für Herstellung von Sandwichplatten

- Formgebung kundenspezifischer Isolierteile für HVAC- und Rohrleitungsisolierung

In allen Fällen, verbesserte Oberflächenqualität und Kantengenauigkeit, während die Kosten für Verbrauchsmaterial und die Arbeitsbelastung des Bedieners sanken.

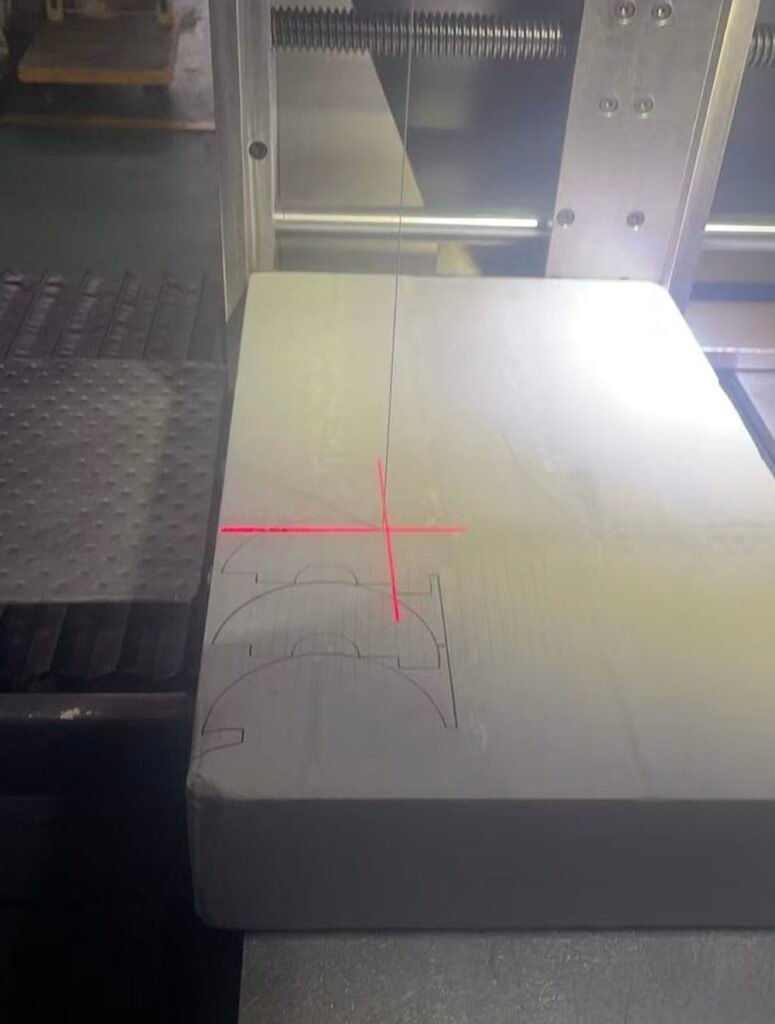

hier ist ein echter Schneidetest für einen unserer Kunden, der ein führendes Unternehmen in der Bauindustrie ist

Schlussfolgerung: Wählen Sie Präzision, um wettbewerbsfähig zu bleiben

Da die Nachfrage nach grüne Gebäude und energieeffiziente Materialien wächst, können sich die Hersteller keinen inkonsistenten oder minderwertigen PU-Zuschnitt leisten. Die Einführung eines Diamantdrahtschneidsystem gewährleistet eine saubere, genaue und skalierbare Verarbeitung von PU-Dämmstoffblöcken - ganz gleich, ob Sie Wärmewandplatten oder präzisionsgefertigte modulare Dämmstoffe herstellen.

Wenn Sie auf der Suche nach einer zuverlässigen, staubfreien und kosteneffizienten Methode zum Schneiden von PU-Blöcken sind, ist unser Diamant-Seilsäge-Lösungen kann Ihnen helfen, Ihre Produktionslinie zu verbessern.

📩 Kontaktieren Sie uns heute um eine Vorführung zu vereinbaren oder mehr über das präzise Schneiden von PU-Dämmstoffblöcken zu erfahren.