グラファイト外形切断機は、鋭く滑らかで均一な切断を実現するために、細部までこだわって作られています。余分な無駄なく、きれいに、そして正確に切断できます。これらの機械は時間とコストを節約し、あらゆる作業で美しい仕上がりを実現します。安定性、高速性、そして使いやすさを追求して設計されているため、作業は軽快で安全です。これらの機械は、スピード、精度、そして無駄の削減を1つのツールで実現します。これにより、より多くの作業をより高品質に行うことができます。.

グラファイト切削におけるCNCの役割

CNCグラファイトカッティングは、複雑な細部の作業や迅速な切断に最適です。グラファイトブロックをより短時間で、より丁寧に成形できます。CNCはコンピュータコードで作業するため、すべての切断面が均一に仕上がります。これにより、ミスが減り、無駄が最小限に抑えられます。曲線、角度、細い線などの作業がはるかに容易になります。CNCは安全で、繰り返し作業も容易であり、小規模な工場でも大規模な工場でも優れた性能を発揮します。CNCを使用すれば、最も困難な作業もシンプルで、きれいに、そしてきれいに仕上がります。.

グラファイトプロファイル切断の用途

グラファイト外形切断機 工具工場、金型工場、発電所などで使用されています。内側の形状と外側の形状の両方を丁寧に、そして細部まで切削します。作業員は、円、溝、穴、鋭利なエッジなどを作るためにこれを使用します。適切な機械を使用すれば、細い線や小さな形状も滑らかに仕上げることができます。様々な分野の様々なプロジェクトに活用できます。あらゆる種類のグラファイトブロックに適しています。これらのブロックは、最高の耐久性を実現するために特別に設計されています。.

正確な仕上げを実現するためのツール

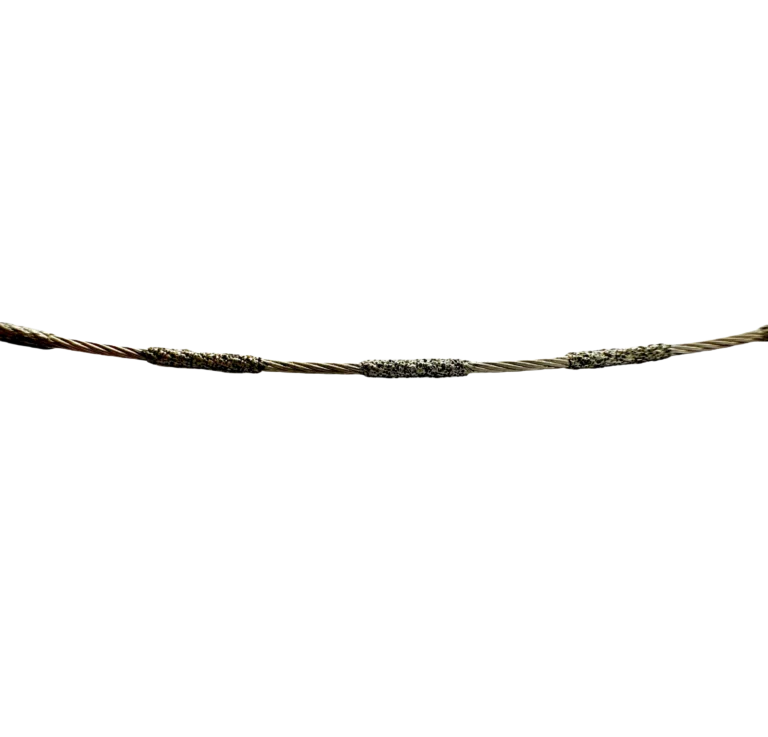

優れたグラファイト切断工具を使うと、作業がより安全、簡単、そしてスムーズになります。グラファイト用のダイヤモンドワイヤーソーなどの工具は、きれいな切断面と少ない粉塵で作業できます。この工具はブロックを安全に保ち、見た目も美しい薄いスライスを作成できます。作業者は材料を無駄にすることなく、より多くの部品を製造できます。適切な刃を使うことで、切断面は平らで滑らか、そしてしっかりとした仕上がりになります。最適な工具を選ぶことで、作業が速くなり、仕上がりもはるかに良くなります。.

グラファイトスライシングマシン

グラファイトスライシングマシンは薄片の製造に最適です。大きなブロックを迅速かつ丁寧に平らなシートに切断します。これらの機械は、研究所、発電所、工場などで使用されています。得られたシートは平らで滑らかであり、多くの作業に不可欠です。薄片は金型、試験、または動力部品に使用されます。このツールは、きれいなスライスを製造し、時間を節約し、材料の使用量を削減することで知られています。.

グラファイトワイヤー切断工具

グラファイトワイヤーカッティングは、細いワイヤーを用いてブロックを精密かつ丁寧に切断する手法です。時間はかかりますが、切断面は美しく滑らかで、鋭い角と美しい側面が長持ちします。ワイヤーカッティングは、通常のノコギリでは不可能な細かい作業に最適です。多くの作業場では、時間はかかっても、最高の仕上がりを求めてこの方法を採用しています。.

グラファイトカッティングソー

グラファイトカッティングソーは、シンプルながらも便利な工具です。小規模な作業場から大規模な工場まで幅広く使用されています。適切な刃を使用すれば、スムーズに切断でき、粉塵の発生を抑え、ブロックを安全に保管できます。使いやすく、作業者にとって安全で、ほとんど手入れをしなくても長年お使いいただけます。シンプルで丈夫、そしてきれいな切断ができるため、多くの作業場で愛用されています。.

グラファイト加工装置

安全で効率的、そしてクリーンな作業には、高品質のグラファイト加工機器が不可欠です。このセットには、CNC工作機械、ワイヤーソー、スライシングマシン、ブロックカッターが含まれています。それぞれの工具には独自の役割がありますが、これらを組み合わせることで作業がはるかに容易になります。適切な機械を使用することで、廃棄物を削減し、時間を節約し、クリーンで安全な部品を製造できます。堅牢な構造と美しい仕上がりが信頼されているため、多くの工場で使用されています。だからこそ、一流ブランドは様々な用途に対応する強力な機械を製造しているのです。.

推奨グラファイト外形切断機

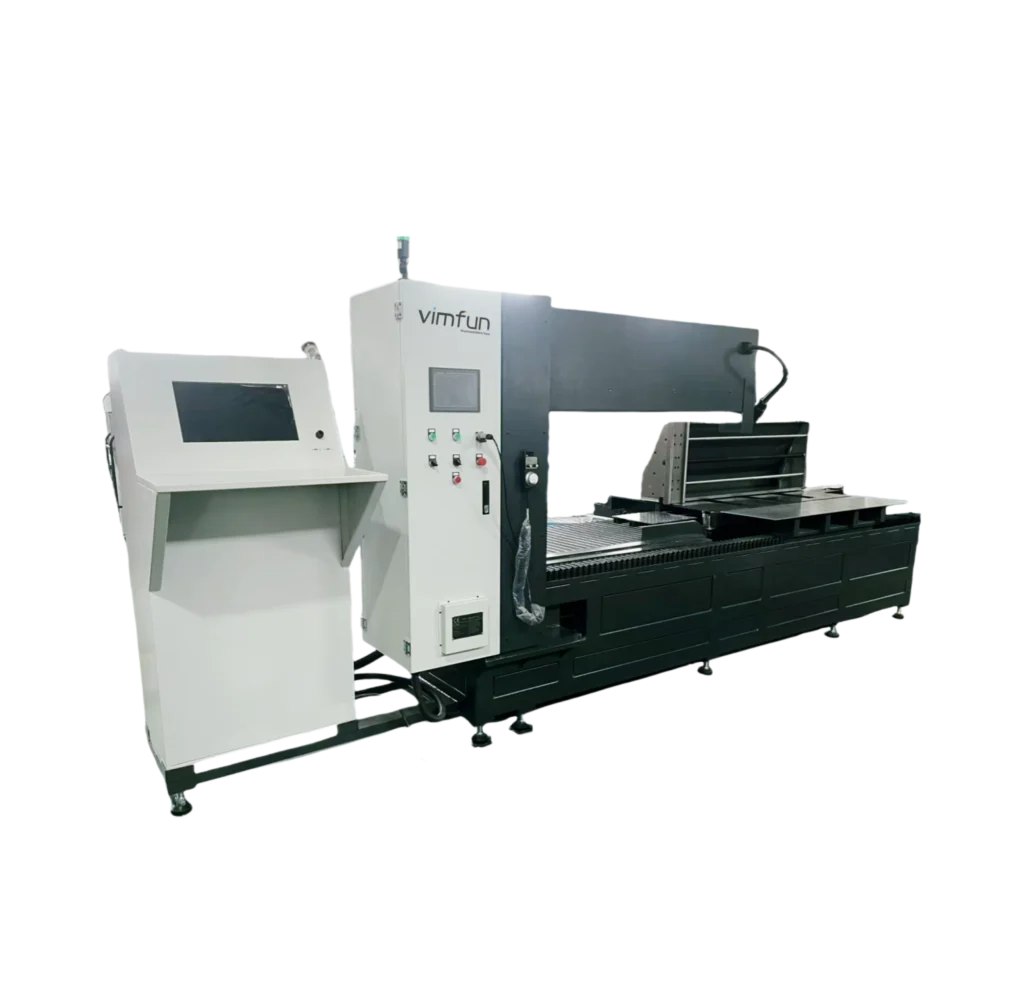

SVI 160-100 CNC自動グラファイト切断機

これは SVI 160-100 このモデルはパワフルで高速です。大規模な作業やグラファイトブロックの加工向けに設計されています。CNCシステムにより、すべての切断面が均一に仕上がります。毎日重労働を行う工場に最適です。このマシンは、そのスピード、パワー、そして美しい仕上がりで高い信頼を得ています。.

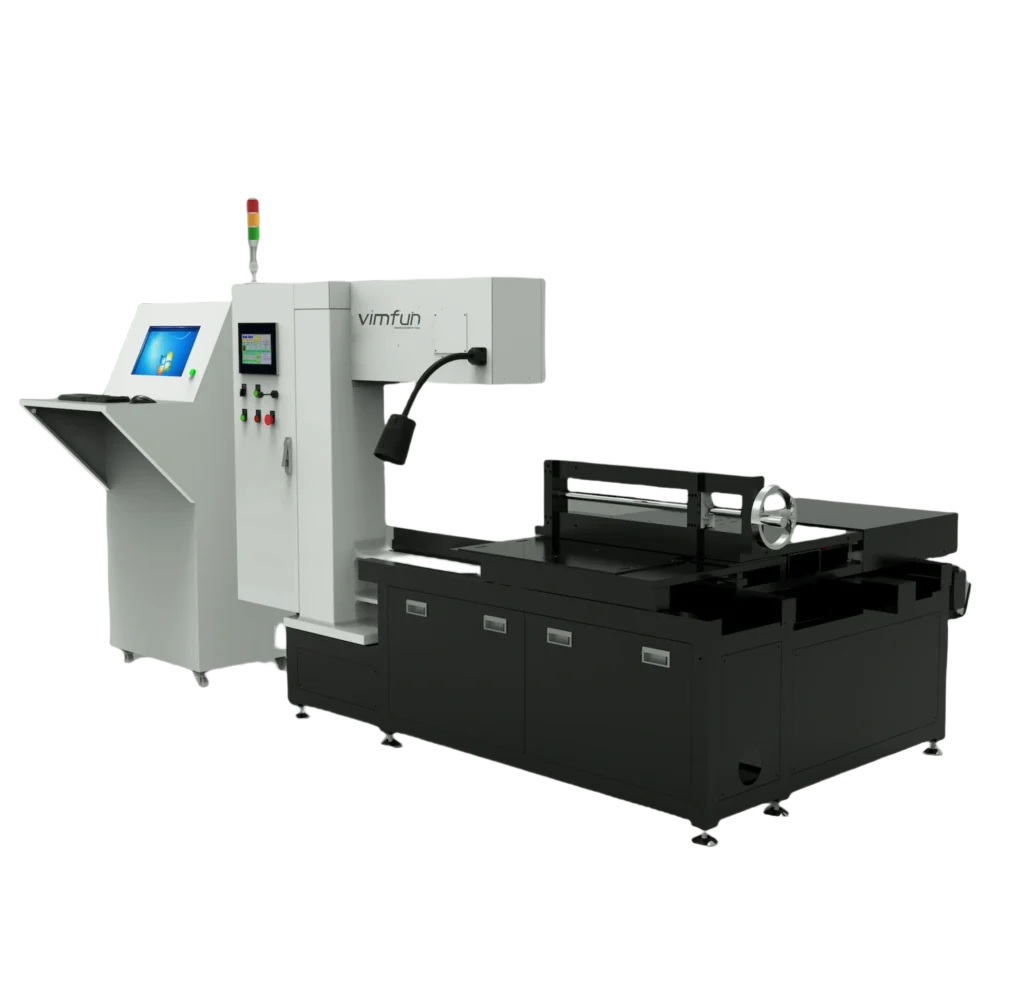

SVI 60-60 グラファイト外形切断機

これは SVI 60-60 モデルは小型ですが、非常に頑丈です。外面カットときれいなエッジに最適です。使いやすく、シャープな形状を素早く作ることができます。正確なプロファイルと滑らかなカットが求められる工場に最適です。安全で頑丈、毎日の作業に最適です。.

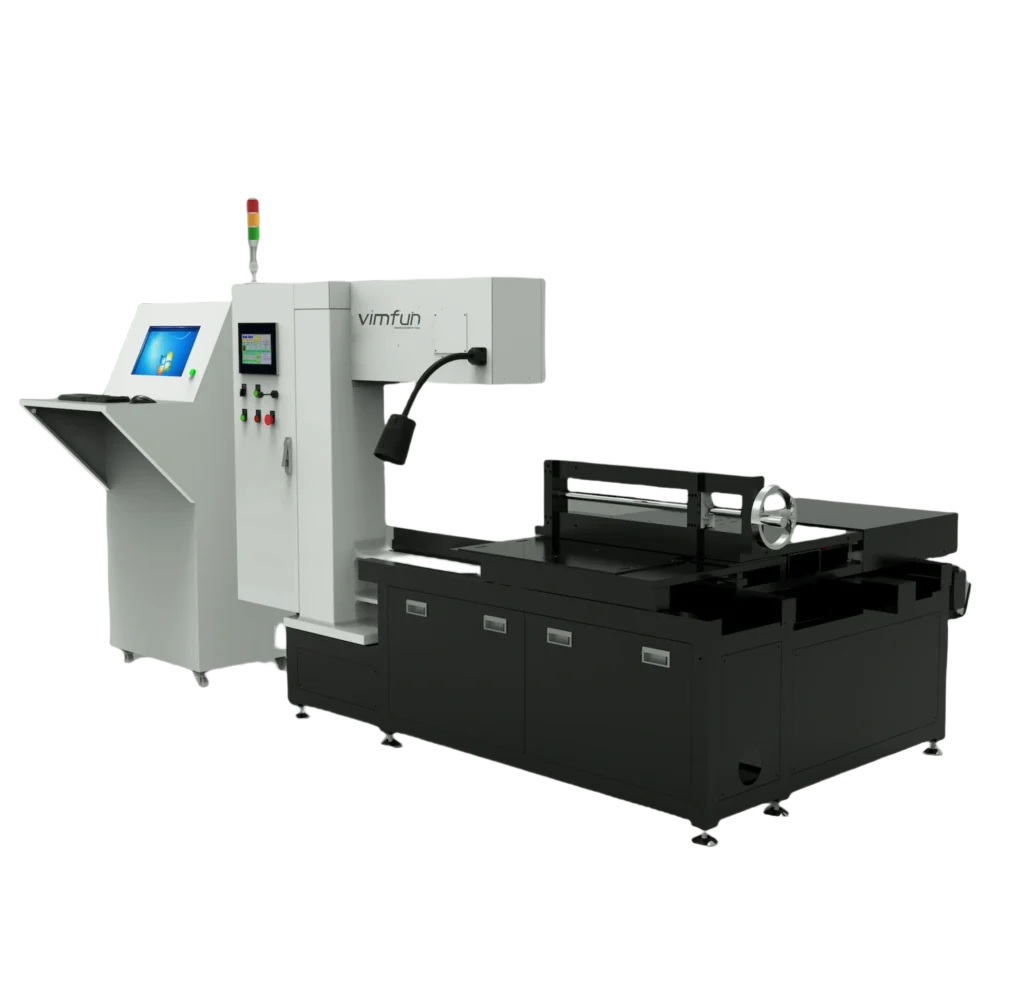

SVI 80-80 グラファイト インナープロファイル切断機

これは SVI 80-80 このモデルは、内面の切削や細かい作業に最適です。穴、曲線、その他の内面形状の切削に最適です。短時間できれいな仕上がりを実現します。細かい作業が求められる工具メーカー、研究室、工場などに最適です。シャープできれい、そして滑らかな仕上がりが期待できます。.

グラファイト外形切断機の機能

| マシンモデル | 主な用途 | ベストフィーチャー |

| SVI 160-100 CNC | 大きなブロックカット | 高速で強力なCNC |

| SVI 60-60 | 外形カット | 小さくてすっきりとシャープ |

| SVI 80-80 | 内側の形状カット | きれいで詳細なカット |

VIMFUNを選択して精度を得る

ヴィムファン VIMFUNは、グラファイト外形切断機の信頼できるブランドです。VIMFUNの機械は堅牢で安全、そして革新的な設計で構築されています。VIMFUNは、長寿命で要求の厳しい作業にも優れた性能を発揮する工具を開発しています。ウェブサイトでは、全モデルの詳細をご覧いただけます。VIMFUNは、高品質な製品とサービスで、多くの業界から信頼を得ています。VIMFUNにアクセスして、お客様のニーズに最適な機械をお選びください。.

用途 グラファイト外形切断機 正確な形状ときれいなラインを実現します。あらゆる作業において、より高い価値、シャープなディテール、そして滑らかな仕上がりを実現します。.

よくある質問

薄切りに最適なツールは何ですか?

薄いシートにはグラファイト外形切断機が最適です。.

外側のプロファイルに最適な機械はどれですか?

SVI 60-60 はグラファイト外側プロファイルの切断に最適です。.

大きなグラファイトのブロックを切断できますか?

はい、SVI 160-100 CNC は大型ブロックに最適です。.

信頼できるグラファイト マシンを製造しているのは誰ですか?

VIMFUNはグラファイト加工装置のトップブランドです。.

内側の形状に最適なマシンはどれですか?

SVI 80-80 はグラファイトの内部プロファイルの切断に最適です。.

最もきれいに切断できるツールは何ですか?

グラファイトワイヤー切断とグラファイト用ダイヤモンドワイヤーソーは、ほこりの少ない完璧なエッジを作ります。.