グラファイトの切断は決して簡単なものではありません。多くの作業員は、間違った工具を使うと作業に苦労します。通常のノコギリやワイヤーは、すぐに壊れたり、摩耗が早すぎたり、表面に深く粗い跡を残したりすることがあります。これは時間と材料の無駄につながります。だからこそ、耐摩耗性グラファイト切断ワイヤーは非常に強力なツールなのです。滑らかできれいな切断を実現し、汚れや無駄を減らします。時間と労力を節約し、作業の安全性を高めます。また、この種のワイヤーは標準的なワイヤーよりもはるかに長持ちするため、コスト削減にもつながります。多くの工場や産業において、作業規模の大小を問わず、グラファイトブロックの切断に最適なワイヤーとして認識されています。.

耐摩耗性グラファイト切断ワイヤーを使用する理由

これは グラファイト切断ワイヤ 作業がより美しく、よりきれいに仕上がります。標準的なワイヤーはすぐに切れ味が鈍くなり、切断面も粗くなります。その結果、切断ブロックが無駄になり、仕上がりも悪くなります。しかし、耐摩耗性ケーブルは、損傷に強く、長時間鋭い切れ味を保つように設計されています。外側に強力な層があるため、ワイヤーの安全性が確保され、より少ない力で切断できます。そのため、作業者は作業の途中で頻繁に作業を中断してワイヤーを交換する必要がありません。時間の経過とともに、1メートルあたりのグラファイトワイヤー切断コスト全体が削減されます。このワイヤーは、優れた品質、きれいな切断、そして長期的なコスト削減を求めるショップにとって最適な選択肢です。.

より良い結果をもたらすワイヤーコーティング

このワイヤーの重要な部分は、特殊なコーティングです。グラファイト切断用のワイヤーコーティングは、ワイヤーの強度と安全性を高めます。作業中にワイヤーが切れるのを防ぎます。また、このコーティングは、グラファイト切断時に問題となる粉塵の付着も防ぎます。粉塵が付着しないため、ワイヤーはよりスムーズに滑り、よりきれいな切断が可能になります。コーティングにより、ワイヤーの寿命が長くなり、切断が容易になり、作業場も清潔に保たれます。作業全体の安全性、速度、そしてコスト効率が大幅に向上します。.

グラファイト切断に最適な張力

ワイヤーにかかる張力、つまり張力は、良い結果を得るために非常に重要です。ワイヤーは、グラファイトの切断に最適な張力で、滑らかでまっすぐな線を描きます。ワイヤーを強く引っ張りすぎると、突然切れてしまう可能性があります。一方、緩すぎると、ワイヤーが曲がってしまい、表面にざらざらとした跡が残ることがあります。適切なバランスを保つことで、最良の切断結果が得られ、ワイヤーの寿命が長くなり、廃棄物も削減されます。適切な張力は切断機の損傷を防ぐため、作業場にとってもコスト削減につながります。小さな一歩が、大きな成果を生むのです。.

正確な精度のグラファイト切断ワイヤー

接続可能ダイヤモンドワイヤー

の 接続可能ダイヤモンドワイヤー シンプル、迅速、そしてスマート。作業中にワイヤーが切れても、すぐにつなぎ直すことができます。つまり、長時間の休憩を取らずに作業を続行できます。修理に特別な工具や訓練は必要ありません。そのため、短時間で結果を出す必要があり、長時間の作業停止が許されない作業場にとって、このワイヤーは賢明な選択となります。多くの人がこのワイヤーを選ぶのは、時間の節約、ストレスの軽減、そして切断作業全体のスムーズさを実感しているからです。.

グラファイト切断用ダイヤモンドワイヤー

の グラファイト切断用ダイヤモンドワイヤー 表面に微細なダイヤモンド粒子が散りばめられています。これらの小さなダイヤモンドポイントは、まるで複数の鋭利な刃が同時に切断するかのように機能します。グラファイトを素早く、きれいに、そして非常に正確に切断します。このワイヤーは安全に使用でき、小規模な作業場から工場での作業まで幅広く対応できます。多くのユーザーのニーズを満たすため、多くのグラファイト切断ワイヤーサプライヤーから信頼を得ています。強度が高く、耐久性が高く、切断速度が速いため、市場で最も人気のあるワイヤーの一つとなっています。.

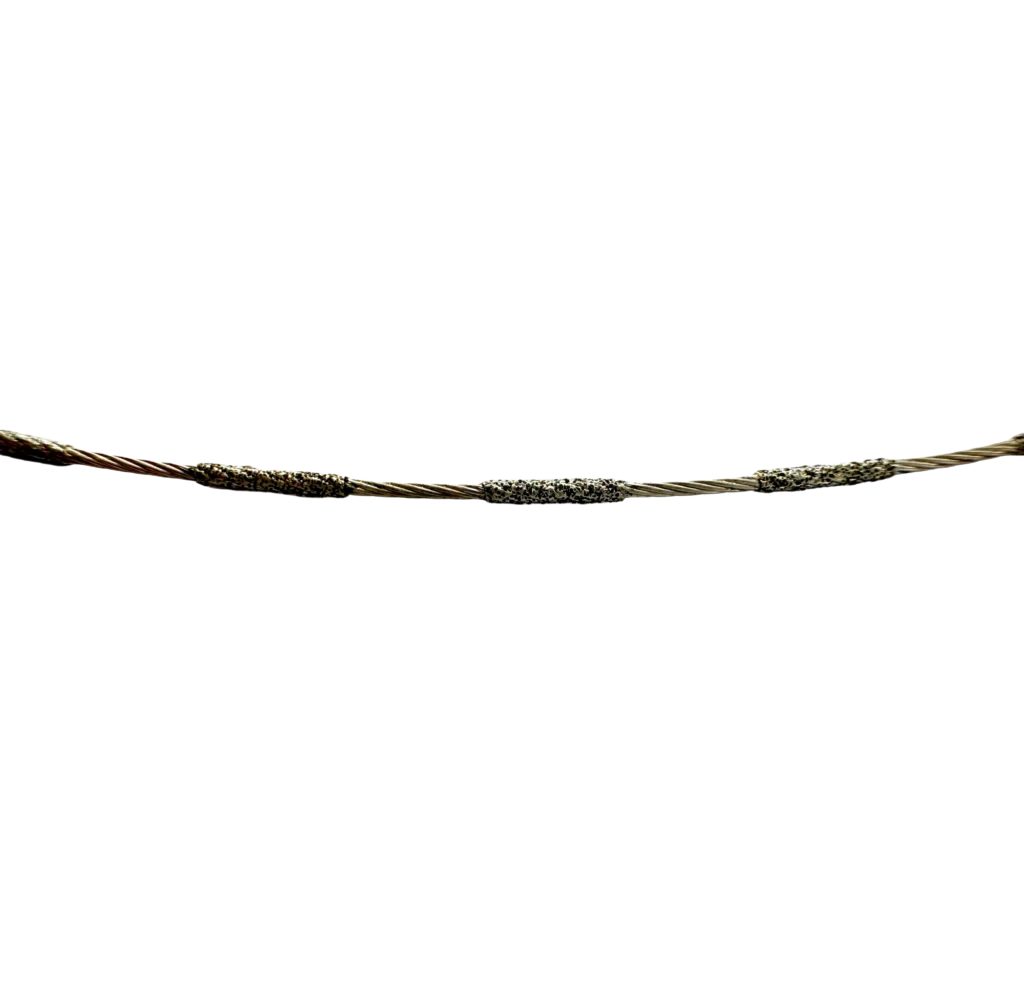

グラファイト切断用セグメントダイヤモンド・ワイヤー

の グラファイト切断用セグメントダイヤモンド・ワイヤー セグメントと呼ばれる特殊な切断部を備えています。これらの部品は、切断中に熱を分散させるのに役立ちます。これにより、ワイヤーの過熱や破損を防ぎます。熱をコントロールすることで、ワイヤーの寿命が延び、強度も維持されます。また、切断グラファイトワイヤーの摩耗問題も軽減されます。このタイプのワイヤーは、長時間連続して作業する作業に最適です。安定した切断を実現し、作業者の安全を確保し、損傷の可能性を低減します。.

グラファイト切断用スパイラルコートダイヤモンドワイヤー

の グラファイト切断用スパイラルコートダイヤモンドワイヤー スパイラル状に巻かれたワイヤーです。この形状によりワイヤーのグリップが向上し、ブロック上をよりスムーズに移動できます。スパイラル状に巻かれたワイヤーは粉塵を拡散させ、詰まりを防ぎます。これにより、汚れや清掃の手間が減り、仕上がりも向上します。グラファイトシートの切断など、常に滑らかで均一な切断が求められる産業用ワイヤーに最適です。また、スパイラル状に巻かれたワイヤーは、品質を損なうことなく切断速度を速めます。短時間できれいな仕上がりを求める工場にとって、最適な選択肢です。.

ダイヤモンドワイヤーとグラファイト切断ワイヤー

多くの人がダイヤモンドワイヤと グラファイト切断ワイヤ. ダイヤモンドワイヤーは硬い粒子で覆われているため、高速かつきれいに切断できます。一方、グラファイトワイヤーは柔らかく脆いブロックに適しています。どちらも優れた性能を発揮しますが、作業内容によって適切なワイヤーを選ぶ必要があります。適切なワイヤーを選べば、時間と費用を節約しながら、より良い結果が得られます。また、使用する鋸と作業内容に適したグラファイト切断ワイヤーのサイズも重要です。.

グラファイト切断ワイヤーの最適な用途と主な特徴

| ワイヤータイプ | ベストユース | 主な特徴 |

| 接続可能ダイヤモンドワイヤー | 仕事中のクイックフィックス | ダウンタイムが少なく、再参加も簡単 |

| グラファイト切断用ダイヤモンドワイヤー | カッティングブロックとシート | きれいで正確なカット |

| グラファイト切断用セグメントダイヤモンド・ワイヤー | 高温作業での長時間使用 | 発熱が少なく、摩耗も少ない |

| グラファイト切断用スパイラルコートダイヤモンドワイヤー | 薄板の切断 | 強力なグリップ、ほこりが少ない |

グラファイトソー用ワイヤーのメンテナンス

ワイヤーのお手入れは非常に重要です。使用後は必ず清掃してください。錆を防ぐため、乾燥した場所に保管してください。作業を始める前に、適切な張力(引っ張り具合)に調整してください。これらの簡単な手順は、グラファイトソー用のワイヤーをメンテナンスし、常に最適な状態に保つのに役立ちます。適切に手入れされたワイヤーは長持ちし、スムーズに切断でき、機械を損傷から保護します。また、適切な手入れを行うことで、作業中にワイヤーが切れて多くの時間を無駄にするリスクを軽減できます。.

適切なサイズの選択

沢山あります グラファイト切断ワイヤ ワイヤーには様々なサイズがあり、作業内容によって適切なサイズが異なります。薄い板材や細かい部分の切断には細いワイヤーが最適です。大きくて強度の高いグラファイトブロックには太いワイヤーが適しています。間違ったサイズを使用すると、切断不良、時間の無駄、ワイヤーの断線につながる可能性があります。ワイヤーを選ぶ前に、必ずお使いの機械と作業内容をご確認ください。適切なサイズを使用することで、作業はより速く、より安全に、よりきれいに、より確実に行えます。.

グラファイト切断ワイヤーを購入するのに最適な場所

安全で丈夫なワイヤーを購入するには、 ヴィムファン. VIMFUNは、グラファイト切断ワイヤーのリーディングサプライヤーとして信頼され、知られています。コネクタ式ワイヤー、ダイヤモンドワイヤー、セグメントワイヤー、スパイラルコーティングワイヤーなど、様々な種類のワイヤーを取り扱っています。それぞれのワイヤーは強度と安全性が試験されています。VIMFUNは、作業員がケーブルを正しく使用し、適切に管理するためのガイドも提供しています。そのため、VIMFUNは工場や店舗の両方にとって優れた選択肢となっています。VIMFUNから購入することで、長寿命で、きれいに切断でき、作業の安全性を確保できるワイヤーを手に入れることができます。.

よくある質問

グラファイトブロックを切断するのに最適なワイヤーは何ですか?

ダイヤモンドワイヤーは、グラファイトブロックの切断に最適なワイヤーです。きれいな切断面と素早い作業性を実現し、材料の節約にもなります。.

切断グラファイトワイヤの摩耗問題を軽減するにはどうすればよいですか?

グラファイトを切断する際は、常に適切な引っ張り力で切断し、強力なワイヤーコーティングが施されたワイヤーを選択してください。これにより、ワイヤーの寿命が長くなり、作業効率が向上します。.

グラファイトワイヤーの切断コストは、サイズ、コーティング、種類によって1メートルあたりで変動します。VIMFUNは、最高品質でありながら適正な価格をご提供いたします。.

シートとブロックの両方に 1 本のワイヤを使用できますか?

はい、可能ですが、それぞれの作業に適したワイヤーを使用する方が賢明です。グラファイトシート切断用の工業用ワイヤーはシートに最適で、ダイヤモンドワイヤーはブロックに最適です。.