The best horizontal graphite cutting machine helps cut graphite with precision and accuracy. Because of its softness, graphite is easily broken. As a result, the machine has to hold the block carefully while cutting it smoothly and slowly. A graphite block horizontal cutting machine operates in a flat position, ensuring the block remains steady during cutting. This makes straight cuts and smooth edges. When the cut is clean, less graphite is wasted. This saves money and time. Many factories utilize this type of machine to produce parts that must be of uniform size every time. Good cutting also means less extra work after the cut is done.

Best Horizontal Graphite Cutting Machine for Smooth Cuts

の best horizontal graphite cutting machine is particularly well-suited for graphite, as the block lies flat on the table, allowing for precise cutting. This keeps the block stable and safe during cutting. A graphite slab horizontal cutting equipment setup spreads pressure evenly across the block. This helps stop cracks and chips on the edges. Dust from graphite falls to the ground instead of flying around. This makes dust collection easier and safer. The operator can clearly see the cutting line and control the depth better. As a result, each cut appears clean and smooth. Large slabs and small parts can both be cut with good results using horizontal cutting.

Key features to look for

A good cutting machine must be strong and stable. To prevent shaking during cutting, the frame has to be strong. The blade travels in a straight path with the aid of smooth rails and guides. The graphite block must be reliably held in place by the clamp system to keep it from moving. A dust cover and dust port are crucial for maintaining safety and cleanliness. A high precision horizontal graphite cutter allows the user to control speed and depth in small increments. This is useful for thin and thick graphite blocks. When all these features work together, the machine cuts better and lasts longer.

Precision and accuracy matter most

Precision is essential when cutting graphite parts. A CNC horizontal graphite machining center utilizes digital control to move the cutter with great accuracy. This helps make the same cut repeatedly without mistakes. Accurate cutting means parts fit well with other parts. It also means less grinding or sanding later. The control system need to be simple to use and modify. Waste is reduced and quality is consistently excellent when the machine cuts to precise scales. This is very important for parts used in tools, molds, and machines.

Automation and productivity gains

An automatic best horizontal graphite cutting machine helps reduce manual work. The machine can move the block, start cutting, and stop by itself. This saves time and effort for workers. Automatic cutting also reduces human error. The operator can set the program and let the machine do the work. This is helpful for large orders and repeat jobs. Automation enables more cuts to be made in less time. It also helps maintain consistent cut quality from start to finish. This increases total production and improves work speed.

Durability and heavy use

For daily and long work hours, a heavy-duty best horizontal graphite cutting machine is needed. These machines are built with strong frames and powerful motors. They can cut thick and large graphite blocks without damage. Strong parts do not wear out quickly. Good sealing prevents dust from accumulating on moving parts. This helps the machine last longer. When a machine is durable, breakdowns are fewer. This reduces repair costs and lost work time. Heavy-duty machines are a good choice for busy factories and workshops.

Cost, value, and affordability

An affordable best horizontal graphite cutting machine should give good performance at a fair price. Low cost is insufficient on its own. Also, the machine should be long-lasting and cut accurately. A cheap machine that breaks frequently will ultimately cost more in the long run. Consider power usage, spare parts, and service support. A machine that is easy to clean and maintain saves time and effort. Good value means strong build, steady cutting, and low waste. Choosing wisely helps the business grow without extra cost.

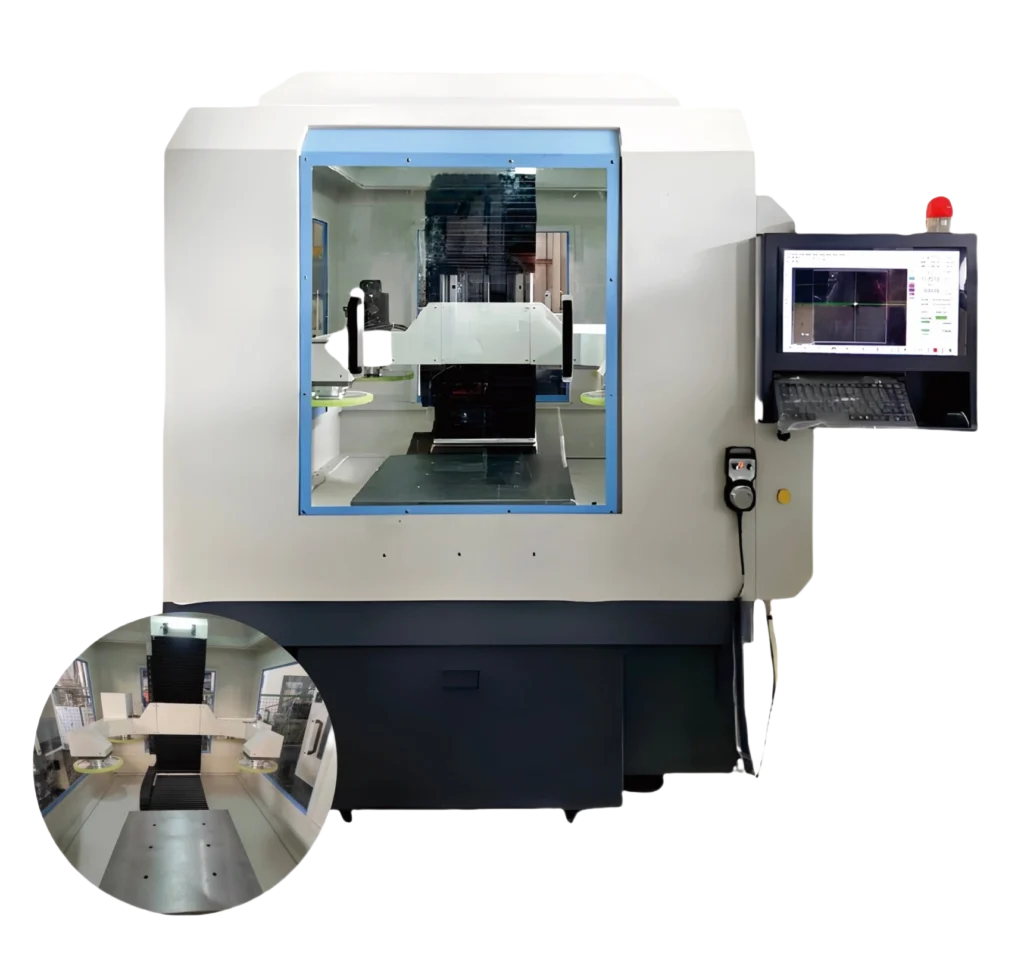

SH 60-60 横型黒鉛切断機

の SH 60-60 best horizontal graphite cutting machine is made for clean and straight graphite cutting. It holds the graphite block firmly and cuts with a smooth motion. The strong frame helps reduce vibration during work. This gives neat edges and less chipping. The control panel is simple and easy to use. The operator can easily set the speed and depth. The machine works well for blocks, slabs, and electrodes. It also includes a dust port for easy dust control. Maintenance is simple, and daily cleaning is fast.

- Strong and stable body

- Easy control system

- Clean and smooth cutting results

Safety and maintenance tips

The advantages of graphite dust are excellent, it has to be handled carefully. To prevent dust exposure, always utilize a vacuum system or dust collector. Wear safety glasses and a dust mask while working. Keep the clamps tight before starting the cut. Clean dust from the rails and guides daily. Check belts and moving parts often. Use the correct cutting speed for each block size. The equipment stays precise and safe when properly maintained. The equipment may operate effectively for many years with regular maintenance.

Features of the best horizontal graphite cutting machine

| 特徴 | Benefit |

| 高精度 | Clean and exact cuts |

| Strong frame | Less vibration |

| ダストコントロール | Safer workspace |

| オートメーション | Faster work |

| Heavy-duty build | Long machine life |

| Good value | Saves money |

| SH 60-60 | Reliable and easy to use |

Choose the Best Graphite Cutting Solution Now

At ヴィムファン, we help you find the best horizontal graphite cutting machine for clean and smooth graphite cutting. Our machines are robust, easy to use, and designed for daily use. We understand that every job is unique, so our team helps you select the option that best suits your needs. With Vimfun, you get good quality, easy support, and honest service. We care about your work and the results you achieve. Our cutting machines enhance your cutting work with ease and confidence.

Choosing the best horizontal graphite cutting machine means good cutting and a strong build. A good machine cuts cleanly, generates less waste, and lasts longer. It keeps work easy, safe, and smooth.

よくある質問

- What is the best horizontal graphite cutting machine?

The best machine cuts graphite clean, works long, and wastes less.

- Why is horizontal cutting good for graphite?

Horizontal cutting keeps the block flat and gives smooth, safe cuts.

- What types of graphite can this machine cut?

It can easily cut blocks, slabs, and electrodes with ease.

- How safe is horizontal graphite cutting?

It is safe if you use clamps and dust control.

- How long does a good machine last?

A well-maintained machine can last for many years.