A CNC Automatic Graphite Cutting Machine is a modern machine used in factories. It cuts graphite securely and precisely. Graphite is soft, but it may shatter quickly. That is why careful cutting is so important. A computer is in charge of this machine. The computer follows the same instructions every time. It helps in cutting graphite blocks into smooth, clean pieces. The machine works automatically, so it saves time. It also reduces human mistakes. Many companies use this machinery because it produces high-quality, clean cuts.

Importance of Graphite Cutting in Industrial Applications

Graphite is used in many industries. These include metal work, electronics, batteries, and energy systems. These industries need graphite parts in the right size and shape. The surface also needs to be smooth. If graphite is cut poorly, it can break and result in waste. This increases cost. A CNC自動グラファイト切断機 helps avoid these problems. It carefully and safely cuts graphite. Graphite dust is also reduced by it. The factory is safer for workers when there is less dust. For cutting graphite, many manufacturers use CNC machines.

How CNC Graphite Cutting Technology Works

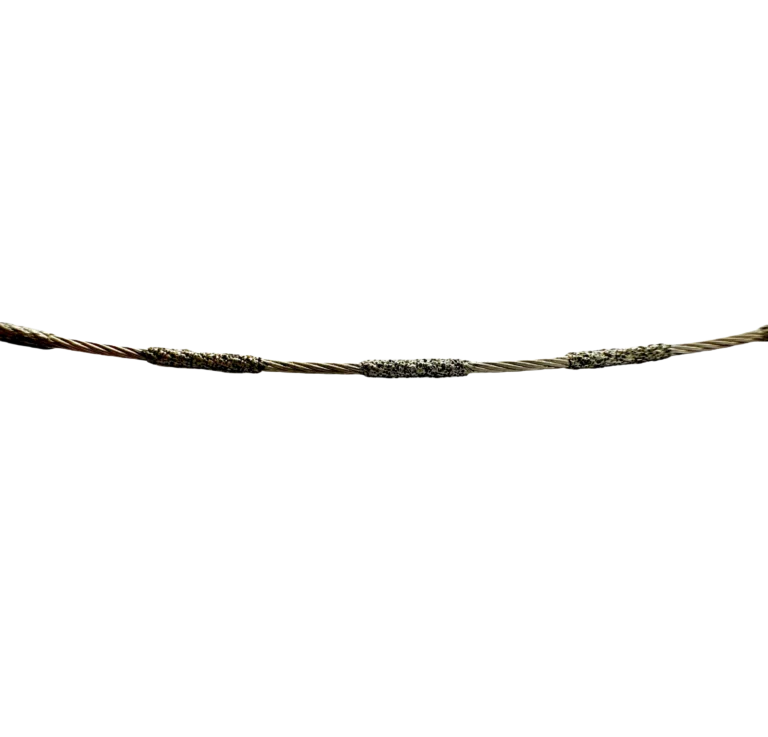

This cutting machine works with a computer system. Every machine movement is controlled by the computer. Before cutting begins, the cutting way is set up. As a result, the work is precise and efficient. An endless diamond wire saw is used in many machines. This wire cuts graphite gently and evenly. The wire moves in a continuous loop. It does not shake the graphite block. A Diamond Wire Cutting Machine with a constant-loop design delivers clean cuts. It also helps prevent cracks. This cutting method is soft, safe, and very effective.

Advantages of Automated CNC Slicing

Automated CNC Slicing makes graphite cutting easy and stable. The machine works the same way every time, so the results do not change. It reduces human work and lowers the chance of errors. Because diamond wire is used, heat and pressure stay low during cutting. This keeps the graphite strong and smooth. Automated slicing also helps factories work faster and finish more jobs in less time.

Large Graphite Block Slicing Capabilities

Large Graphite Block Slicing requires a strong, stable machine. Big graphite blocks are heavy and can break if the machine is weak. A CNC自動グラファイト切断機 is built with a solid frame to safely hold large blocks. The Continuous Loop Diamond Wire cuts through the block slowly and evenly. This helps produce flat slices of uniform thickness. These slices are ready for further use in factories.

Role of Endless Diamond Wire Saw Technology

The Endless Diamond Wire Saw is one of the most important parts of graphite cutting. It uses a wire coated with diamond particles to cut smoothly. Unlike sharp blades, diamond wire does not damage the edges. A Diamond Wire Cutting Machine utilising this system can work for long hours without stopping. It also reduces waste and improves surface quality. This makes it a smart choice for industrial graphite cutting.

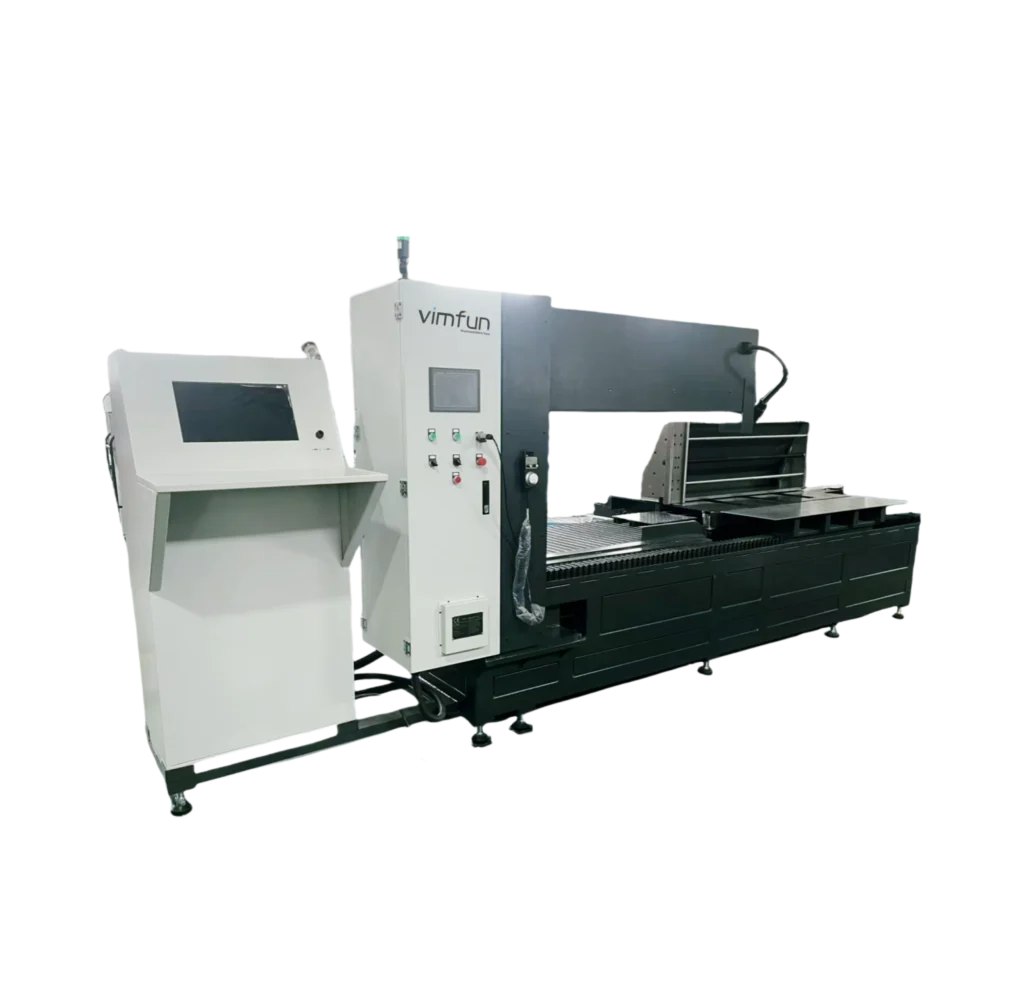

SVI 160-100 CNC自動グラファイト切断機

の SVI 160-100 CNC自動グラファイト切断機 is designed for heavy industrial work. It supports automated CNC slicing and delivers stable, accurate cutting. This machine uses CNC Graphite Cutter technology to control speed and movement. It is suitable for large graphite block slicing and works with an Endless Diamond Wire Saw system. The machine’s robust body helps reduce vibration and improve cutting quality.

主な特徴:

- Accurate CNC control for clean cuts

- Endless Diamond Wire Saw for smooth slicing

- Strong structure for large graphite blocks

- Safe operation with less dust

Benefits of CNC Automatic Graphite Cutting Machine

を使用している。 CNC自動グラファイト切断機 gives many benefits to factories. It improves cutting quality and reduces material use. Automation reduces worker effort and enhances safety. The machine also works faster than manual cutting methods. Because it uses diamond wire, tool life is longer, and maintenance costs are lower. These benefits help industries grow and meet high production needs.

Traditional Cutting vs CNC Diamond Wire Cutting

Traditional cutting methods often use blades that cause cracks and rough edges. These methods also create more dust and waste. A Diamond Wire Cutting Machine works better. It cuts smoothly and maintains the graphite’s shape. CNC control ensures the same result every time. This is why many industries now prefer CNC graphite cutting over old methods.

Suitable Applications Across Industries

CNC自動グラファイト切断機 are used in many fields. These include battery production, electrode making, solar energy parts, and aerospace materials. The machine can cut both small and large graphite blocks. Automated CNC slicing also supports custom shapes and special sizes. This flexibility makes the machine useful for many industrial needs.

Choose Smart Graphite Cutting with Vimfun

Make your graphite cutting work better with Vimfun. We provide simple and strong CNC machines made for factory use. Our CNC Automatic Graphite Cutting Machine helps you cut graphite safely and cleanly. It gives smooth cuts and steady results every day. The machine is easy to use and built to last. It helps save time and reduce waste. Many industries trust ヴィムファン for reliable cutting work. If you want easy operation, safe working, and better production, Vimfun is ready to help. Contact Vimfun today and start improving your work.

A CNC Automatic Graphite Cutting Machine cuts graphite safely and cleanly. Machines like the SVI 160-100 make cutting simple. It is good for fast, accurate work in factories.

よくある質問

- How does it cut graphite?

It uses CNC control and a diamond wire to make smooth and even cuts.

- Why is it better than normal cutting?

It is safer, faster, and gives more accurate and cleaner results.

- What industries use it?

Factories that make batteries, electrodes, electronics, and energy parts.

- What is the SVI 160-100?

It is a strong CNC machine that makes cutting large graphite blocks easy and steady.

- 時間と材料を節約できますか?

Yes, it cuts fast, reduces waste, and gives smooth results every time.

- 労働者にとって安全ですか?

Yes, it makes less dust and needs less manual work, so it is safer.