グラファイトは強度がある一方で柔らかく、粉塵も出やすいため、切断は難しい場合があります。だからこそ、素早く正確に、そして失敗のない機械が必要なのです。プロレベルの グラファイトカッティングソー 完璧です。様々な種類のグラファイトに対応し、毎回きれいにカットできます。さらに、スマートなテクノロジーがカットを楽にし、安全性も確保します。.

グラファイトは、金型、電池、電極、耐熱部品の製造において、今日では非常に有用です。そのため、 CNCグラファイト切断機 は必須です。自動グラファイト切断機を導入すれば、チームの時間を節約し、廃棄物を減らし、労力をかけずにより多くの成果を上げることができます。制御された切断動作は、作業スペースを整理整頓するのにも役立ちます。.

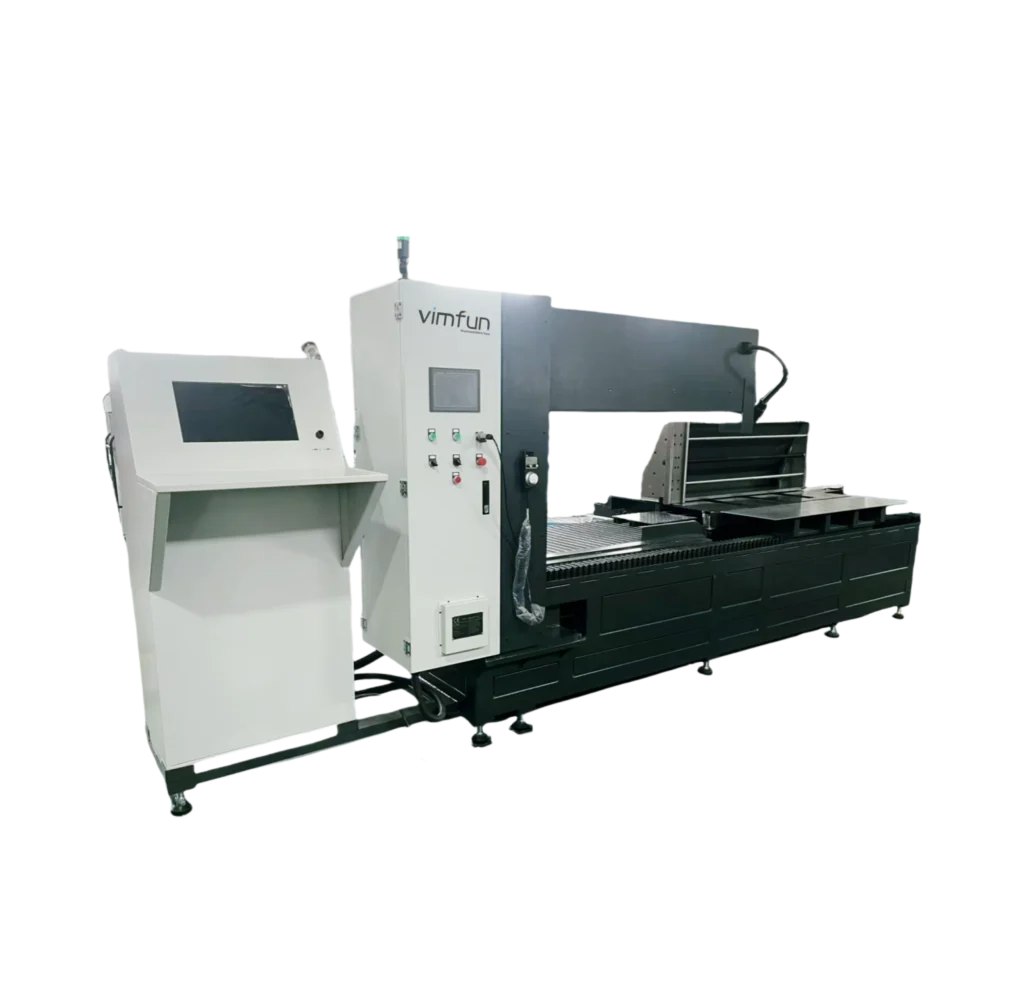

高効率自動グラファイトソー

これは グラファイトカッティングソー 巨大なグラファイトブロックを素早く正確に切断できるように設計されています。.

の SVI 160-100 CNC自動グラファイト切断機 頑丈なフレームを使用しているので、大きなものを切るときも安定します。グラファイトを置くテーブルは正確なレールの上を滑るので、カットは毎回非常にきれいに仕上がります。.

ダイヤモンドワイヤーがぐるぐると回転し、一方向にノンストップで切断します。これにより、無駄をほとんどなく、平らな切断面が得られます。また、従来の切断方法では時々発生する切断面の跡も防ぎます。.

CNCシステム搭載で、作業は超簡単。厚さを設定してスタートボタンを押すだけで、あとは自動で切り出してくれます。最大1600mm×1000mmのグラファイトブロックにも対応できるので、大きな作業に最適です。しかも、精度は±0.05mmと非常に正確です。.

スクリーンは操作が簡単で、切断時に粉塵がほとんど出ません。 ダイヤモンドワイヤーグラファイトソー 丈夫で長持ちし、修理もほとんど必要ありません。.

自動グラファイト切断技術を選ぶ理由

自動切断は、人為的なミスを減らすことから人気が高まっています。機械が作業を行うと、切断面は均一で滑らかになります。操作者はプログラムを入力するだけで、あとは鋸がやってくれます。シンプルで安全です。.

自動化のもう一つの大きな利点は、精度です。これらは 自動グラファイトブロックカッター 細部に至るまで指示に従います。疲れたり集中力が途切れたりしないので、カットはいつも同じ仕上がりになります。小さなミスが大きな問題を引き起こす可能性があるので、これは非常に重要です。.

自動化技術は廃棄物の削減にもつながります。機械がグラファイトを正しく切断すれば、不良品が減り、コスト削減につながります。また、機械が切断経路と粉塵を制御するため、清潔さも維持されます。.

すべてのグラファイトグレードで安定した切削性能

グラファイトには様々な種類があります。柔らかくて成形しやすいものもあれば、釘のように硬くて切るのが難しいものもあります。優れたグラファイト切断ノコギリなら、どんな素材にも難なく対応できます。切断中に揺れが起こらない頑丈な構造で、均一で滑らかな切断を実現します。.

この機械はワイヤーや刃を安定させてくれます。もし大きく揺れると、切り口がきれいに仕上がらなくなります。しかし、このノコギリは揺れを防ぐように設計されており、最初から最後まで安定した性能を発揮します。.

この安定した切断は、ぴったりと合う部品を作るための鍵です。少しでもずれると、金型や電極を作る際に問題が発生する可能性があります。安定した切断であれば、不均一さを心配する必要はありません。.

高精度できれいで均一なカットを実現

良質なグラファイトカッティングソーの最大の利点の一つは、その精度の高さです。この機械は、ほぼ誤差なく切断できるよう設計されています。つまり、必要なサイズを正確にカットでき、切り口は滑らかで、ざらつきがありません。.

秘密は切断ワイヤーまたは刃とスマートな制御システムにあります。 グラファイト加工および成形ツール 速度と締め付け具合を調整することで、カットを細かくまっすぐに保ちます。これにより、毎回最高の仕上がりを実現します。.

スムーズな操作のための高度な安全機能

安全は重要です。良い グラファイトカッティングソー 安全機能を搭載し、作業者全員の安全を確保します。切断エリアの周囲にはガードが付いており、ほこりや破片が飛び散るのを防ぎます。.

一部のセンサーは、異常が発生した場合に鋸の動作を停止させることができます。ワイヤーが断線したり、何かが正しく配置されていない場合、機械は事故を防ぐために停止します。これにより、安全性が確保され、機械が保護されます。.

もう1つの便利な機能は、使用していないときに自動的に電源が切れることです。これにより電力を節約できます。.

これらの安全システムにより、作業者はストレスなく仕事に集中できます。機械はミスを防ぎ、作業エリアの安全を確保します。.

生産性向上のための高速処理速度

現代の グラファイトカッティングソー スピードが命です。手作業よりもはるかに速くグラファイトを切断します。強力なモーターと制御されたワイヤーにより、品質を犠牲にすることなく、作業を迅速に完了します。.

スピードアップはどんなビジネスにとっても大きなメリットです!材料を素早く切断できれば、より短時間でより多くの製品を生産できます。これは注文に常に対応するための鍵です。機械の速度が速ければ、工場は人員を増やすことなくより多くの製品を生産でき、お客様を待たせることもなくなります。.

これらの機械は全力で稼働している時でも安定しているので、速度と品質のどちらかを選ぶ必要はありません。こうしたバランスの良さから、自動グラファイトソーが選ばれています。.

さまざまな用途に合わせてカスタマイズ可能な切断設定

それぞれの作業は異なるため、それに対応できるツールが必要です。薄くスライスする必要がある作業もあれば、深く切ったり、奇妙な形にしたりする必要がある作業もあります。. グラファイト切断鋸 各カットを完璧にするために変更できるオプションがあります。.

つまり、ワイヤーの速度、締め付け具合、切断深度、そして送り速度を自由にコントロールできるのです。つまり、あらゆる素材や形状に合わせてマシンを微調整できるということです。そして嬉しいことに、これらの設定はすべて保存でき、クリックするだけで後で再利用できます!

これら 工業用グラファイト加工鋸 簡単に変更できるので、あらゆるプロジェクトに最適です。シンプルなカットから大胆なデザインまで、何でもできます。.

自動グラファイト切断の恩恵を受ける業界

多くの産業でグラファイトによる正確な切断が求められています。電子機器メーカーはバッテリーや回路にグラファイト部品を使用しています。金型メーカーは金属の成形にグラファイトブロックを使用しています。太陽光発電業界では、太陽光パネルの製造にグラファイトを使用しています。航空機業界でも、超高熱に耐えられる部品にグラファイトが使用されています。.

研究室やアーティストもこれらの機械を使用しています。研究室では実験のために正確な形状を必要とし、アーティストは彫刻にグラファイトブロックを使用します。自動化された機械は、これらすべての用途においてきれいなカットを実現します。.

当社のグラファイト切断鋸を選ぶ理由

適切なカッティングマシンを選ぶことは非常に重要です。当社のグラファイトカッティングソーは、安定性、高速性、安全性、そして超高精度を兼ね備えた優れた製品です。あらゆる種類のグラファイトを切断でき、常にきれいな仕上がりを実現します。.

ヴィムファン 専門分野 グラファイト電極切断システム グラファイトと硬質材料向け!私たちは技術、精度、そしてお客様のニーズに合った機械の製造に注力しています。当社の機械は、世界中の企業がより速く、よりきれいに、より正確にグラファイトを切断するのを支援しています。.

ヴィムファン 高精度グラファイトスライス装置 頑丈な作りです。あらゆる場所で力強く作業でき、何時間も切っても安定感を保ちます。各マシンがスムーズかつ安全に動作するよう、綿密な設計を採用しています。設定変更も可能なので、簡単なカットから難しい形状まで、同じマシンで様々なカットが可能です。.

よくある質問

グラファイト切断鋸とは何ですか?

グラファイトをきれいに、素早く、正確に切断する機械です。.

あらゆる種類のグラファイトを切断できますか?

はい、ソフト、ミディアム、ハードグラファイトで機能します。.

使用しても安全ですか?

確かに、安全を確保するためのセンサーとガードが付いています。.

どれくらい速く走れますか?

速く切れますが、切れ味は滑らかで均一です。.

Vimfun を選ぶ理由は何ですか?

Vimfun は、正確で信頼性の高い素晴らしいダイヤモンドワイヤー切断機を製造しています。.