Вам нужно нарезать предметы с предельной точностью? Алмазная проволочная пила с ЧПУ Это может быть именно то, что вам нужно! Многие предприятия используют эти пилы, потому что они быстрые и мощные, обеспечивая действительно ровные разрезы каждый раз. Если вы работаете с такими материалами, как камень, стекло или силикон, то это может вам подойти. CNC алмазный станок для резки проволоки Мы справимся с ними без труда. Давайте посмотрим, что делает нашу проволочную пилу особенной и как она может помочь вам в ваших проектах.

Ознакомьтесь с высококачественной алмазной проволочной пилой с ЧПУ.

Сайт SVR 50 НА 50 Это умный и мощный станок для резки, который отлично подходит для придания деталям из графита круглой формы особенно гладкого вида.

Он способен разрезать графитовые стержни, трубки и контейнеры, не оставляя трещин и не создавая беспорядка. Проволочная заготовка обеспечивает исключительно плавный рез, благодаря чему получаются аккуратные разрезы с минимальным количеством отходов. Только представьте, сколько денег и времени вы сэкономите!

Кроме того, вот это Пила для резки алмазной проволоки с ЧПУ Он может полностью вращаться сам по себе. Вращая графит, он обеспечивает одинаковую толщину каждого слоя, поэтому результаты всегда получаются ровными и идеальными. Его даже можно использовать без воды или охлаждающей жидкости, что очень удобно для упрощения работы.

С помощью SVR 50-50 вы можете задавать необходимую толщину каждого среза или даже обрабатывать материал большими группами. Прочный зажим надежно фиксирует графит, предотвращая его перемещение. Это означает, что каждый срез будет чистым и идеальным.

Что делает нашу алмазную проволочную пилу с ЧПУ уникальной?

Наш сайт Пила для резки алмазной проволоки с ЧПУ Особенность этой модели в том, что она отлично режет, а управление очень простое в освоении. Она использует компьютерные команды для перемещения проволоки с действительно высокой точностью, поэтому каждый разрез получается безупречным и ровным. прецизионная алмазная проволочная пила Также имеет прочное основание, поэтому он остается неподвижным во время резки. Это обеспечивает устойчивость проволоки и помогает избежать ошибок. Самое приятное? Он прост в использовании; вам не нужно быть гуру, чтобы им пользоваться. На экране четко отображаются все команды, поэтому вы легко сможете следить за процессом и контролировать ситуацию.

Технология высокоточной резки твердых материалов

Резка твердых или хрупких материалов может быть сложной задачей. Неправильная резка может привести к трещинам или браку. Именно поэтому точность так важна. Наша алмазная проволочная пила с ЧПУ использует датчики для контроля скорости проволоки, давления и направления её движения. Эти датчики быстро реагируют на любые изменения в материале. автоматизированная система резки алмазной проволокой Режет аккуратно и мощно, не прилагая чрезмерных усилий и не работая слишком быстро. Камень, кварц, керамика, кремний, мрамор или стекло — станок надежно защищает материал и обеспечивает превосходный результат резки. Именно поэтому люди доверяют этому инструменту.

Получайте идеально ровные и чистые срезы

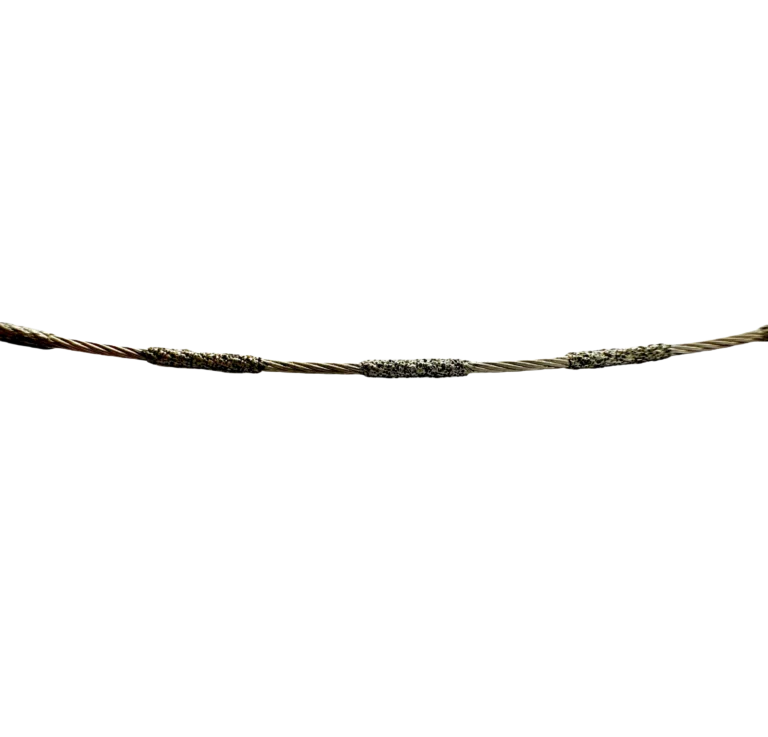

Качественный, чистый срез — это не только использование острых инструментов. Это также умение держать инструмент в равновесии и применять правильное усилие. Пила для резки алмазной проволоки с ЧПУ Станок оснащен проволокой, покрытой крупными алмазами, способной разрезать твердые материалы, не повреждая и не царапая их. Благодаря компьютерному управлению движениями станка, каждый этап резки проходит по плавной траектории. Станок не останавливается внезапно и не натыкается на неровности, а это равномерное движение делает поверхность гладкой и готовой к дальнейшей обработке. Многие наши клиенты говорят, что им не приходится тратить много времени на полировку, потому что срезы получаются очень чистыми.

Широкий спектр материалов, которые мы можем точно разрезать.

Одна из самых крутых особенностей этой алмазной пилы с ЧПУ заключается в том, что она может обрабатывать самые разные материалы. Она может резать как мягкие материалы, такие как пенопласт и пластик, так и твердые, например, гранит и сапфир. Даже такие труднообрабатываемые материалы, как кремниевые пластины или стеклянные листы, для нее не проблема. Это делает станок полезным в таких областях, как электроника, строительство, солнечная энергетика, лаборатории и художественные студии. Он может вырезать как простые формы, так и сложные конструкции, поэтому он отлично подходит для творческих и технологических проектов. С помощью всего лишь одного станка можно сделать очень многое.

Передовая автоматизация для более быстрой и стабильной резки.

Поскольку время летит быстро, наша пила использует автоматизацию для ускорения процесса. высокоточная проволочная пила с ЧПУ Система автоматически регулирует скорость протяжки проволоки, скорость резки и движение. Вам не нужно останавливаться, чтобы настраивать параметры! Благодаря меньшему количеству пауз каждый проект выполняется быстрее. Система также устанавливает оптимальную скорость и угол подачи проволоки для каждого материала, что обеспечивает чистоту резки и продлевает срок службы проволоки. Рабочие также чувствуют себя в большей безопасности, поскольку им не нужно так часто возиться с работающим станком.

Индивидуальная раскройка специально для вас

Каждый проект немного отличается. Для некоторых требуются большие куски материала, для других — тонкие слои. Одни формы просты, другие имеют изгибы или острые углы. Мы можем изменить настройки станка в соответствии с вашим дизайном. Если у вас сложная форма или сложный материал, мы изменим скорость подачи проволоки, ее выравнивание и программу в соответствии с вашим рисунком. Независимо от того, необычный или сложный ваш проект, мы поможем вам получить желаемый результат. Это сэкономит вам время, сократит количество отходов и гарантирует, что готовое изделие будет именно таким, каким вы хотели.

Высококачественная алмазная проволока для обеспечения высоких эксплуатационных характеристик.

Сайт Пила для резки алмазной проволоки с ЧПУ камни. Вот почему мы используем прочное оборудование, рассчитанное на длительный срок службы. Алмазы останутся на месте, даже если вы будете их очень часто использовать. Это Промышленный алмазный проволочный резак Проволока не ломается быстро и долго остается острой. Вы можете выполнить больше резов, не меняя проволоку слишком часто. Проволока плавно движется по направляющим колесам, что означает меньший нагрев и трение. Поскольку проволока остается прочной и острой, станок дольше выполняет чистые разрезы и предлагает вам максимальную отдачу от ваших инвестиций.

Контроль качества, которому вы можете доверять

Перед отправкой любой станки мы проводим серьёзные испытания. Проверяется каждая деталь пилы, и наша команда осматривает всё, чтобы убедиться в её безопасной и правильной работе. Эти испытания помогают выявить проблемы на ранней стадии и гарантировать бесперебойную работу станка с самого начала. Вы можете быть уверены, что ваш станок будет работать без сбоев долгие годы.

Безопасность всегда важна.

Безопасность имеет первостепенное значение. Наша Пила для резки алмазной проволоки с ЧПУ Он оснащен средствами безопасности, обеспечивающими вашу защиту, такими как кнопки аварийной остановки, защитные кожухи и датчики, которые автоматически отключают оборудование. Эти датчики остановят машину, если что-то пойдет не так, например, оборвается провод или произойдет вибрация. Пила для резки камня и кристаллов с ЧПУ Также имеются защитные кожухи, предотвращающие разлетание пыли и мелких частиц. Мы также проводим инструктажи и предоставляем четкие инструкции, чтобы вы знали, как безопасно использовать станок. Благодаря этому вы сможете работать уверенно и минимизировать любые опасности.

Итак, почему стоит выбрать именно нашу пилу?

Многим отраслям необходимы чистые, точные и быстрые разрезы. Именно это и обеспечивает наша пила. Нужны тонкие разрезы для пластин? Большие разрезы для камня? А как насчет нестандартных форм и деталей? Наша алмазная проволочная пила для твердых материалов Он справится со всем! Экономит время, уменьшает количество отходов и обеспечивает потрясающий результат. Он создан как для сложных задач, так и для очень точных работ благодаря долговечной проволоке, прочной конструкции и продуманным технологиям. Выбирая нашу проволочную пилу, вы выбираете надежного помощника для ваших проектов по резке.

Вопросы и ответы

Какие материалы можно будет разрезать с помощью этой машины?

Он также может резать камень, стекло, кремний, керамику и множество других твердых или хрупких материалов.

Обеспечивает ли это плавный срез?

Да. Проволока движется равномерно, поэтому каждый срез получается чистым и гладким.

Безопасен ли этот аппарат?

Конечно! У него есть аварийные остановки, защитные кожухи и датчики, которые автоматически отключают его.

Как долго служит алмазная проволока?

Оно прослужит довольно долго, поскольку изготовлено из прочного, высококачественного алмазного материала.

Могу ли я изменить настройки в соответствии со своими потребностями?

Конечно! Вы можете изменить скорость резки, форму и настройки, чтобы получить желаемый результат.