Графит — прочный материал, используемый во многих отраслях промышленности, например, в производстве полупроводников, электроники и других промышленных изделий. Но он также хрупкий, а это значит, что его трудно резать. Обычные инструменты могут вызвать трещины или неровные края. Вот почему... Станок для резки графитового внешнего профиля Это очень полезно. Позволяет получать чистые, точные разрезы, при этом экономя материал и ускоряя процесс!

Эти станки используют сложные системы ЧПУ для придания графиту самых разнообразных и необычных форм. Поэтому, независимо от того, изготавливаете ли вы детали для машин, электроды или что-то совершенно уникальное, вам понадобится хороший станок с ЧПУ.

Усовершенствованный станок для резки графитового внешнего профиля

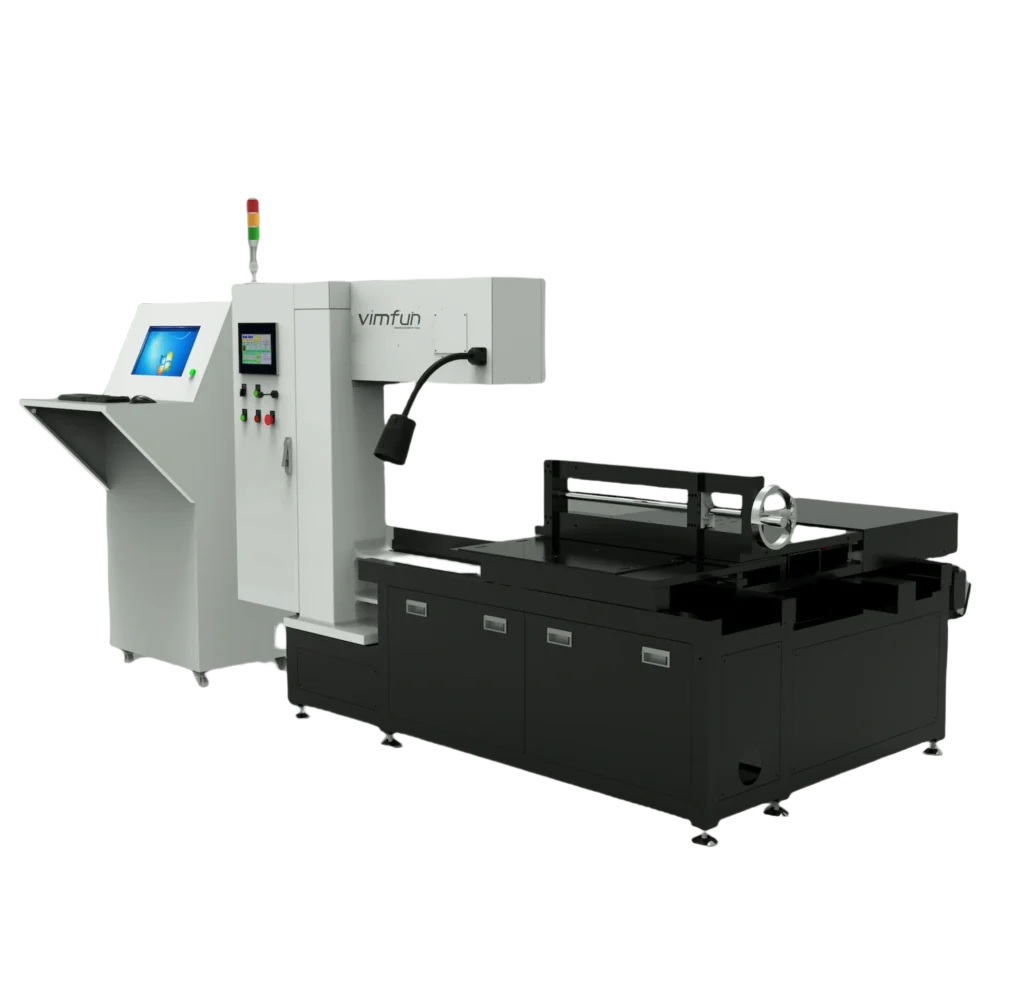

Сайт SVI 60-60 Это мощный станок для резки алмазной проволоки с ЧПУ, предназначенный для бережной резки графитовых блоков.

Благодаря этому кривые, углы и сложные геометрические формы кажутся простыми. Станок для резки графита с ЧПУ Режет чисто, практически без пыли и сколов. Отлично подходит как для изготовления большого количества вещей, так и для простого воплощения какой-либо идеи.

Он имеет прочную раму, обеспечивающую устойчивость при распиловке больших блоков. Стол перемещается по сверхточным направляющим, управляемым ЧПУ. Это гарантирует плавную и точную резку каждый раз.

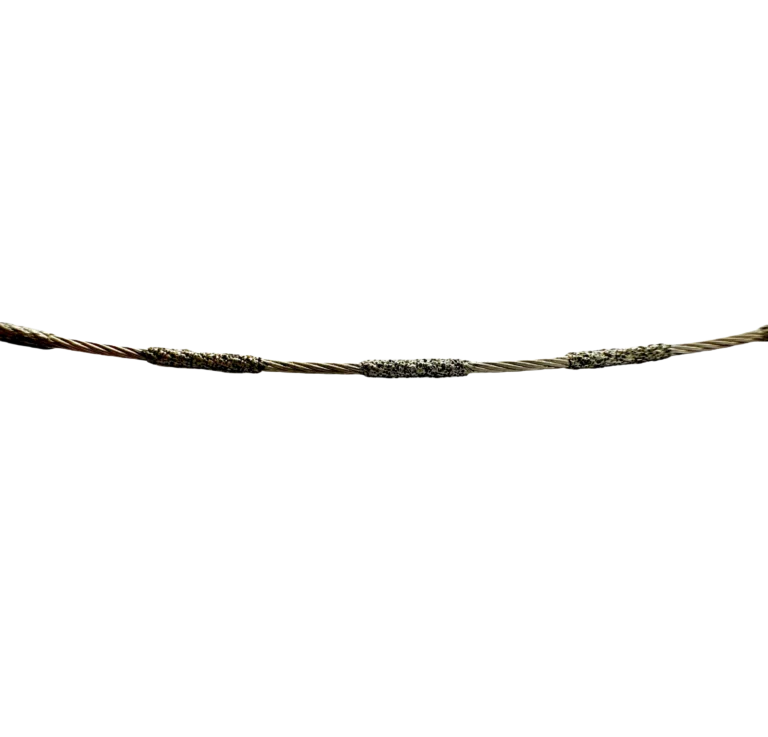

В ней используется алмазная проволока, которая очень быстро режет в одном направлении. Это делает кромки гладкими и ровными. Обычные пилы могут оставлять следы или сколы, но эта — нет.

Вы можете задать желаемую толщину каждого среза и точно вырезать множество деталей, поскольку ЧПУ-станок контролирует весь процесс. Он даже имеет два режима для резки прямых линий или сложных форм. Кроме того, он автоматически удерживает проволоку в натянутом состоянии, даже если вы режете в течение длительного времени.

Принцип работы станка для наружной профилированной резки графита

Это Станок для резки графитового внешнего профиля Используется высокоточная алмазная проволока для резки графита. Она управляется ЧПУ (числовым программным управлением), поэтому проволока точно следует заданному направлению.

Проволока вращается с невероятной скоростью, двигаясь по графиту и аккуратно срезая ненужные участки. В результате получаются гладкие края и желаемая форма. Датчики и программное обеспечение контролируют все параметры, скорость и давление, поэтому трещины отсутствуют, а результаты всегда превосходны.

В отличие от обычных пил, которые могут производить пыль и зазубренные кромки, эти пилы... обработка графитовых блоков Они внимательны, безопасны и выполняют свою работу.

Почему точность важна при резке графита

Когда дело доходит до графита, точность имеет решающее значение. Даже небольшая ошибка может всё испортить. Графит не очень прочный, поэтому грубая резка или слишком сильное давление могут привести к трещинам или поломкам. А это лишь приводит к потерям материала и увеличению затрат.

Тщательная резка гарантирует, что каждая графитовая деталь будет точно такой, какой должна быть. Это имеет огромное значение для таких изделий, как полупроводники, батареи и электроника, где малейшие ошибки могут привести к огромным проблемам.

Особенности нашей системы профильной резки с ЧПУ

Наш сайт станки для резки графитового внешнего профиля Они оснащены множеством компонентов, обеспечивающих их превосходную работу, бесперебойную эксплуатацию и высокую точность. Речь идёт о высокоскоростной алмазной проволоке, ЧПУ-управлении и регулируемом автоматически натяжении.

Точная обработка графита Программа имеет простой способ управления, позволяющий любому программировать сложные фигуры. Она обеспечивает плавное движение проволоки по кривым и углам. Программа даже отслеживает износ и натяжение проволоки, чтобы всё работало идеально. Это предотвращает поломки оборудования и гарантирует неизменно высокое качество.

Передовые технологии резки сложных форм

Детали из графита часто требуют необычной формы. Простые разрезы для этого не подходят. Вот тут-то и возникает проблема. станки для резки графитового внешнего профиля Они сияют. Они могут повторять любую желаемую форму, будь то 2D или 3D, с невероятной точностью.

Алмазная проволока позволяет вырезать крутые кривые и кромки, не повреждая материал. Станок с ЧПУ определяет оптимальный способ резки, регулирует натяжение проволоки и контролирует скорость ее перемещения. Это означает, что даже самые сложные формы получаются гладкими и ровными.

Наибольшую выгоду от этого получают отрасли, требующие графитовых элементов необычной формы, такие как производство полупроводников или электродов на заказ. графит для алмазной проволоки, производители могут выпускать надежные и качественные комплектующие.

Гладкие края с минимальным количеством пыли и износа.

Резка графита может привести к загрязнению, если не соблюдать осторожность. Наши станки для резки графитовых профилей разработаны таким образом, чтобы минимизировать количество пыли и стружки. Резка алмазной проволокой бережно относится к графиту. Натяжение и скорость настроены оптимально, чтобы предотвратить образование трещин.

Всё это означает гладкие кромки, чистые поверхности и практически полное отсутствие отходов материала. Меньшее количество пыли безопаснее, обеспечивает более эффективную работу станка и сокращает объем уборки. Кроме того, это предотвращает слишком быстрый износ алмазной проволоки, что экономит ваши деньги.

Даже на больших и толстых блоках графита можно получить заточку высочайшего качества. Это и делает наши инструменты такими замечательными. Оборудование для фрезерования графитовых профилей Отлично подходит для тонкой работы или изготовления изделий в больших масштабах.

Высокоскоростная работа для массового производства

В производстве время — деньги. Наши станки для резки графитового наружного профиля созданы для быстрой работы без потери точности. Они имеют несколько осей и автоматическое управление, что позволяет им работать без перерыва, делая их идеальными для производства грузов.

Алмазная проволока быстро разрезает материалы, а станки с ЧПУ гарантируют безупречную точность каждого разреза. Это означает, что заводы могут производить больше продукции, сохраняя при этом высокое качество.

Применение в полупроводниковой и промышленной отраслях.

Графит встречается повсюду. В полупроводниковой промышленности он используется для электродов и радиаторов. На заводах его применяют в пресс-формах, подшипниках и других деталях машин.

Станки для резки графитового внешнего профиля Они удобны для работы с материалами самых разных форм и размеров. С их помощью можно резать блоки, стержни, пластины и создавать специальные контуры. Это делает их ценными для всех, кто работает с графитом.

Благодаря точной и чистой резке они сокращают расход материала и повышают надежность деталей. Это особенно важно в отраслях, где производительность имеет первостепенное значение.

Надежная машина, рассчитанная на длительную эксплуатацию.

Резка графита может быть вредна для станков, поэтому вам нужно что-то долговечное. Наш станки для резки графитового внешнего профиля В них используются прочные стальные рамы, мощные двигатели и надежная электроника. Они созданы для работы в сложных условиях.

Если конструкция прослужит дольше, это означает меньше ремонтных работ и меньше простоев. Такие детали, как алмазные проволоки и двигатели, легко заменяются, поэтому поддерживать оборудование в рабочем состоянии не составляет труда.

Прочная конструкция также гарантирует сохранение точности изделия с течением времени. Это ключевой момент для компаний, которым постоянно необходимо производить высококачественные детали из графита.

Возможности индивидуальной настройки специальных графитовых компонентов

В каждой отрасли свои особенности. Для некоторых работ требуются особые формы или методы резки. Наши высокоточные режущие инструменты с ЧПУ его можно доработать в соответствии с этими потребностями.

Вы можете программировать специальные формы, изменять скорость резки и регулировать натяжение проволоки в соответствии с материалом. Есть даже дополнительные модули и программное обеспечение, позволяющие работать с большими блоками или нестандартными кривыми.

Благодаря возможности тонкой настройки, компании могут создавать именно то, что им нужно. Будь то для проверки идеи или для крупномасштабного производства., Промышленные станки для обработки графита Достигать результатов незамедлительно.

Выберите нас в качестве поставщика решений для резки графита.

Vimfun — это имя, которому можно доверять, когда речь идет о станках для алмазной проволочной резки графита. Мы ценим технологии и точность. Наши станки делают обработку графита быстрее, чище и сверхточной.

Мы предлагаем широкий ассортимент станков для резки графита с ЧПУ, подходящих для самых разных задач. Наши станки просты в использовании, работают без сбоев и предназначены для быстрой и точной резки.

С Vimfun вы получаете превосходные технологии, долговечное оборудование и поддержку в любое время. Мы прислушиваемся к нашим клиентам и создаем индивидуальные решения. Выбирая Vimfun, вы получаете лучшее оборудование для резки графита.

Вопросы и ответы

Что такое станок для наружной профилированной резки графита?

Станок, использующий технологию ЧПУ и алмазную проволоку для вырезания из графита сложных форм и фигур.

Почему ЧПУ-резка так важна для обработки графита?

Графит хрупкий материал, и обработка на станках с ЧПУ гарантирует чистые кромки, минимальный отход и высокую точность.

В каких отраслях промышленности используются станки для профильной резки графита?

Полупроводники, электроника, производство батарей, промышленное производство и изготовление графитовых деталей на заказ.

Представляют ли собой сложные формы проблему для станка?

Абсолютно нет! ЧПУ-управление позволяет точно вырезать сложные двухмерные и трехмерные формы.

Почему стоит отдать предпочтение Vimfun при выборе станков для резки графита?

Компания Vimfun специализируется на станках для резки алмазной проволоки, уделяя особое внимание точности, долговечности и быстрой обработке графита.