CNC graphite cutting machines help many shops and plants cut graphite quickly, neatly, and safely. They make every cut smooth and sharp with no waste or extra effort. These machines save time, cut costs, and help do more work in less time. They are built with strong steel, innovative tools, and easy controls so that every job comes out right. Modern industries use them to meet fast needs and get high-quality products each time. Workers like them because they are safe to use, easy to learn, and always give the same good results with less stress. These machines bring speed, care, and trust to every task.

CNC Graphite Cutting Machines for Modern Industries

Today’s industries need fast, safe, and accurate machines. CNC Graphite Cutting Machine solutions are trusted by companies worldwide because they are strong, quick, and straightforward. These machines save much time, lower costs, and give smooth, sharp, and clean cuts. Hand cutting cannot reach this level of detail or speed. They are used for tools, molds, EDM parts, and many other items. With the right CNC machine, any factory can work better, grow faster, and make stronger products with less waste.

Why CNC Graphite Cutting Matters

Graphite is a very special material. It is soft enough to shape, but strong enough to stay solid under heat and pressure. This makes it essential for many industries. Graphite is used for molds, electrodes, and tools in daily work. Cutting it by hand is slow, messy, and not correct. A precision CNC graphite milling machine makes fine, smooth, and precise cuts. It also reduces waste and saves both time and effort. This allows workers to focus on detail and speed. For both large factories and small shops, CNC graphite cutting is now the wise choice.

Benefits of Graphite CNC Machines

- Very high accuracy with each cut

- Longer tool life with less wear

- Safer with dust control systems

- Can cut small shapes and large blocks

- Perfect for EDM electrodes, molds, and block work

A graphite electrode cutting CNC machine is a smart buy for many industries. It makes work easy, safe, and gives much better results.

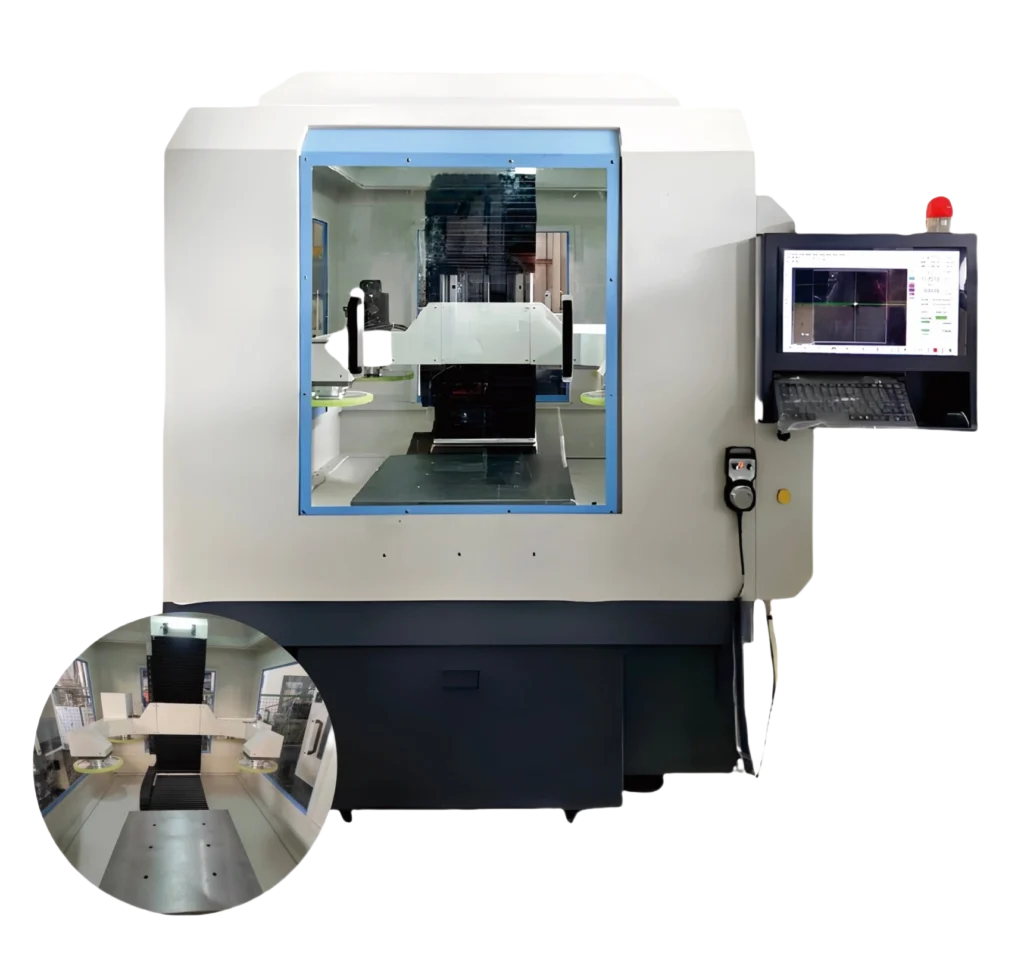

- SH 60-60 Horizontal Graphite Cutting Machine

The SH 60-60 Horizontal Graphite Cutting Machine is stable and strong. It is compact, simple to use, and can fit many types of workshops. It is called the best CNC machine for graphite cutting because it gives both speed and quality. Many companies use it for graphite blocks and molds. This machine is safe, lasts long, and provides good results at a fair cost. Many industries trust it for balanced work.

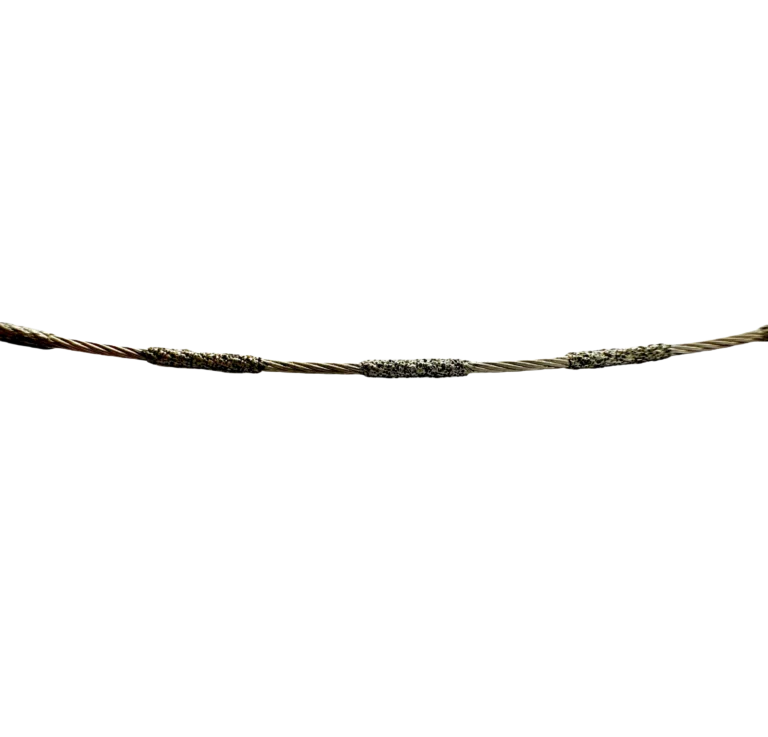

- SV 240-40 high-precision CNC diamond wire cutting machine

The SV 240-40 high-precision CNC diamond wire cutting machine produces fine and clean cuts. It is powerful, runs fast, and makes sharp shapes every time. It is known as an advanced graphite CNC router machine because it can handle work where small details matter most. This machine is the best choice for high-value jobs and projects that need a perfect finish. It is strong, steady, and very reliable.

- SV 60-60 Vertical Graphite Cutting Machine

The SV 60-60 Vertical Graphite Cutting Machine is made for fast, neat, straight vertical cuts. It is called an affordable CNC graphite machining center because it gives high-quality results at a lower cost. Many industries use it for larger graphite parts and easy block cutting. It is simple to use, care for, and strong in daily performance. It is a machine that fits the budget and still gives high output.

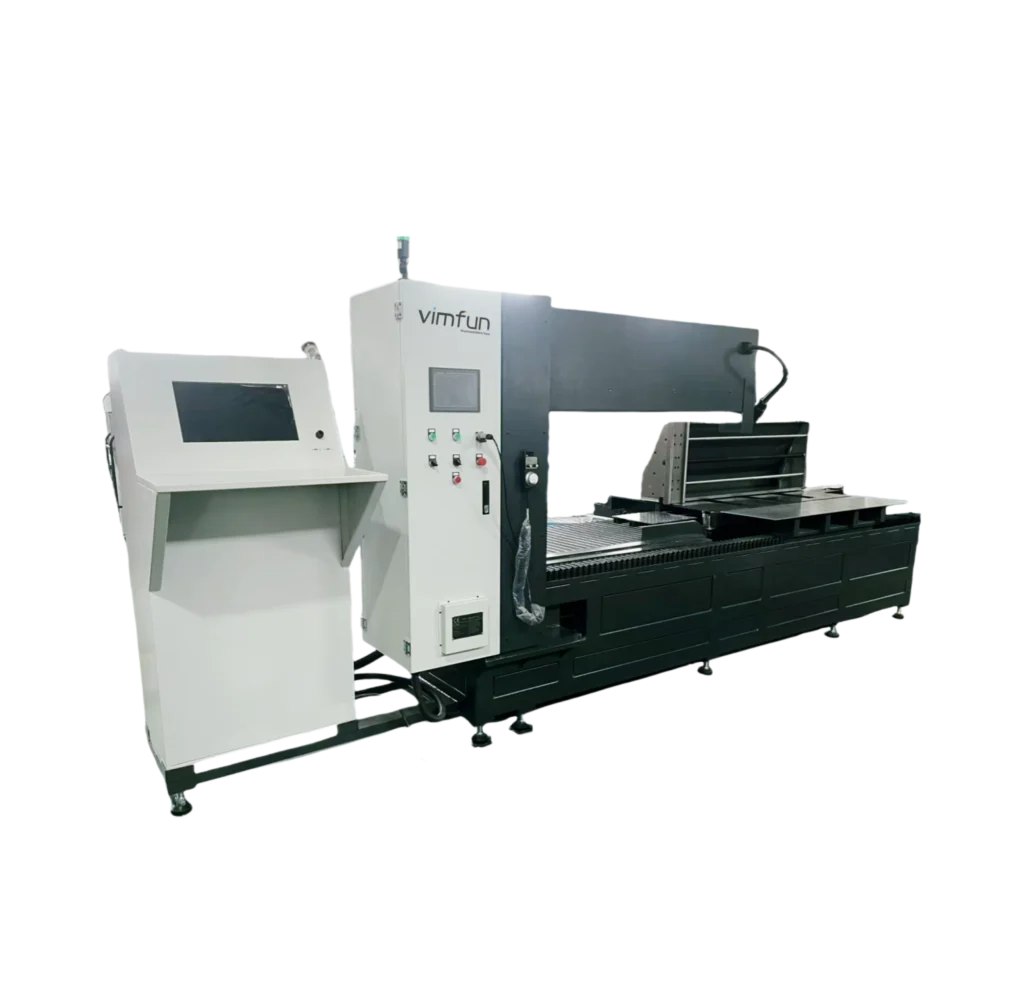

- SVI 160-100 CNC Automatic Graphite Cutting Machine

The SVI 160-100 CNC Automatic Graphite Cutting Machine runs entirely automatically. It cuts faster, saves labor, and supports high production. It is the best CNC machine for graphite block cutting and also works as a graphite mold CNC cutting machine. This is the wise choice for factories with many orders and heavy work. It can run for long hours without slowing, giving quick and clean results. It is a trusted machine for industries that want speed and volume together.

Details About CNC Graphite Cutting Machines

| Machine Model | Cutting Style | Key Feature | Best Use Case |

| SH 60-60 | Horizontal | Compact & stable | Graphite block cutting |

| SV 240-40 | Diamond Wire | Ultra precision | EDM electrodes |

| SV 60-60 | Vertical | Low cost & clean cuts | Large parts |

| SVI 160-100 | Automatic | High-speed automation | Mass production |

Each CNC Graphite Cutting Machine has its own key feature and best use.

Pick Vimfun For Accurate Quality

Vimfun gives trusted CNC graphite machining solutions for all kinds of industries. They offer CNC graphite cutting machine like SH 60-60, SV 240-40, SV 60-60, and SVI 160-100. Each Vimfun machine is safe, quick, and built to last for many years. They focus on strong quality and care for their customers. If you need a machine for molds, blocks, or electrodes, Vimfun is the place to go. Visit Vimfun to explore the CNC graphite cutting machine for EDM electrodes and more models. Vimfun helps industries grow with advanced machines and complete support.

With CNC graphite cutting machines, work is done quickly, cleanly, and safely with less waste. They help companies save money, lower staff stress, and make each job turn out better. They add significant value to projects and help firms reach goals on time. These machines are a strong and trusted tool for daily top results for all modern industries.

FAQs

- Which is the best CNC Graphite Cutting Machine?

The SH 60-60 is best for the balance of speed and price. The SV 240-40 is best for jobs requiring fine detail.

- Can CNC machines cut graphite blocks?

The SVI 160-100 is the best CNC machine for graphite block cutting. It is built for large blocks and heavy jobs.

- Are these machines safe to use?

Yes, all Vimfun machines have dust control and safety covers to keep workers safe and the shop clean.

- Can CNC graphite machines make EDM electrodes?

Yes, a graphite electrode cutting CNC machine is made for EDM and produces strong, high-quality electrodes.

- Where can I buy these machines?

You can buy them at Vimfun. They offer support, delivery, and training for buyers.

- Do these machines need special training?

No, Vimfun machines are simple and easy to use. They come with guides and training help.

- How long do these machines last?

These machines are built with a strong design. With care, they can last many years and give the same good results.

- What industries use these machines?

They are used in tool making, mold design, EDM electrode work, and many other fields. Any company that needs clean and correct graphite cutting can use them.