When you need minimal and exact shapes in graphite, the graphite inner profile cut machine you use matters a lot. A CNC machine for graphite inner profile is built to cut with care, smooth lines, and precise detail, even on tiny shapes. These machines make inside cuts for moulds, tools, custom parts, and tricky shapes that need clean work. With the right machine, you can get high precision graphite profile cut results while saving time, cost, and effort. The work is neat, safe, and simple for large plants and small shops. Graphite inner profile cut machines also reduce waste, make jobs faster, and keep each shape sharp and accurate.

Is Inner Profile Cutting Essential

Inner profile cuts are significant for moulds, custom parts, and jobs that need exact shape and size. Inner profile graphites for moulding tools must be cut to the correct size, with no chips or cracks. Even a small crack can make a mold tool weak or useless. This is why new machines are made for cutting graphite profiles without chips, giving smooth and clean results every time. Inner cuts are used in many fields, like electronics, mould shops, car parts, medical tools, and air and space work. In all these fields, accuracy is key, and even minor errors can lead to large problems.

Factors Affecting Cut Quality

There are many factors affecting quality in graphite profile cuts. Some of the most common are:

- Sharpness of the tool edge

- Machine speed and feed rate

- Density and type of graphite used

- Dust filters and clean air systems

- The skill of the person running the machine

Each factor changes the end result. Dull tools can crack, while sound dust makes the cut face smooth. If the speed is too fast, the edges can break, but if the speed is too slow, the job takes too long. A good balance of these parts is needed to make the best cut with the least waste.

Maintenance of Graphite Machines

Taking care of the machine makes it last longer and work better. Maintenance of graphite profile cut machines should be done often to keep it in good shape. Key steps include:

- Clean the dust filters often

- Replace or sharpen dull tools

- Keep cooling water or air systems working

- Oil the moving parts to stop wear

- Check belts, clamps, and guides to keep cuts steady

When these steps are done on time, the graphite inner profile cut machine runs smoothly and gives clean, sharp shapes. Good care also helps avoid breaks and saves costs over many years. A graphite inner profile cut machine that is well cared for always gives better results.

Graphite Profile Cutting Service

Not all shops or users need to buy a complete machine. Some only need a few parts cut for them. A graphite inner profile cutting service is a good choice in this case. Services like this cut custom shapes and send them ready to the customer. This helps save money, space, and setup time. These services are excellent for small shops, labs, test work, or one-time projects where buying a whole machine is unnecessary. With this service, even small groups can get top-quality graphite parts.

Custom Profile Cuts

Many industries need custom graphite profile cut to spec because standard parts do not always fit. CNC machines make this easy since they can cut shapes according to the exact design. Whether for moulds, dies, or rare parts, CNC machines ensure each piece is neat, smooth, and the correct size. Custom cuts also give freedom to try new ideas, test new designs, and save waste. This is why custom work is in demand across many fields every day.

Machine Options for Better Results

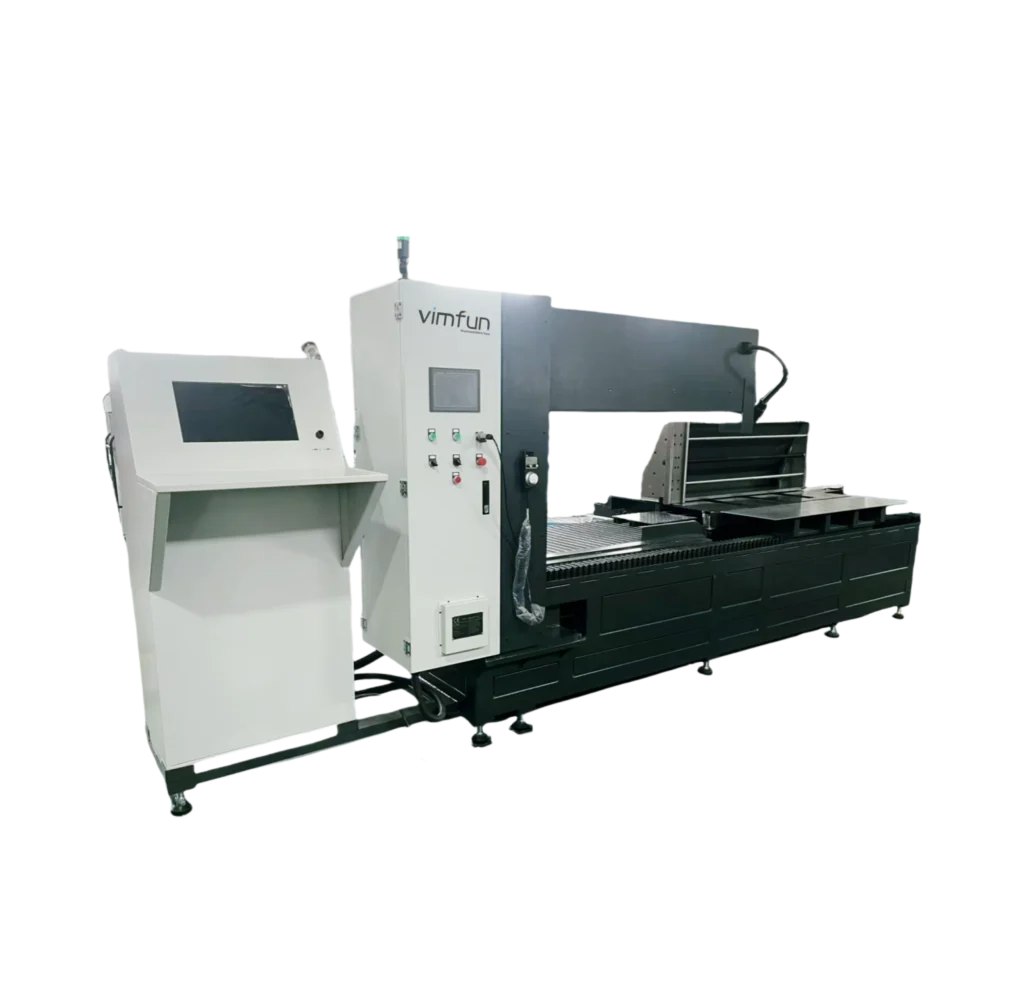

SVI 160-100 CNC Automatic Graphite Cutting Machine

SVI 160-100 Graphite Cutting Machine is built for speed and large jobs. It can handle both inside and outside cuts. It also has a fair graphite profile cutting machine price and gives excellent value. The SVI 160-100 is strong, fast, and a good fit for both large plants and mid-size shops. It is a good choice when you need large runs done quickly.

SVI 60-60 Graphite Outer Profile Cutting Machine

SVI 60-60 machine is made for outer cuts and edges. It has smooth sides, which are perfect for inner profile cut graphite tooling and parts that need complete contour lines. It is small, strong, and easy to run. It also takes up less space, which makes it great for smaller shops. With clean cuts and a strong build, it is a solid pick.

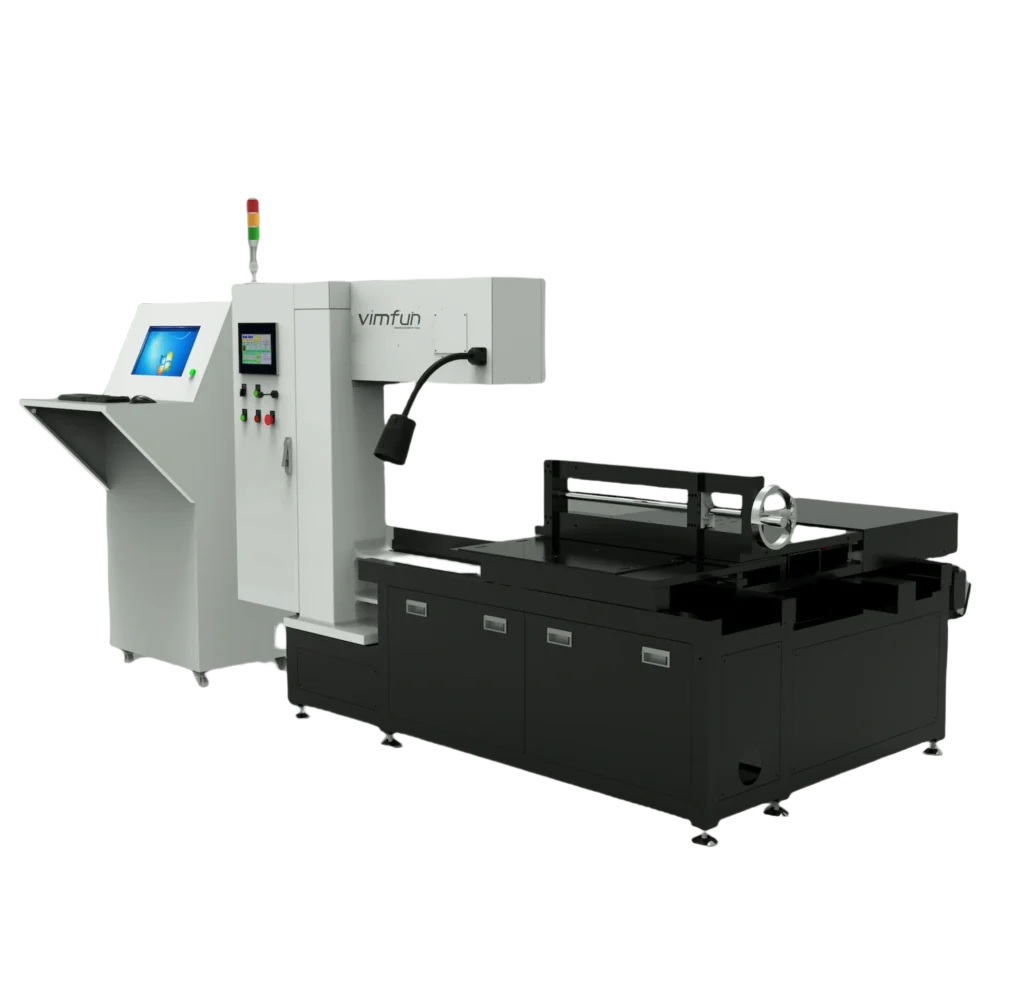

SVI 80-80 Graphite Inner Profile Cutting Machine

SVI 80-80 machine is built for in-depth work. It is a CNC machine for graphite inner profiles that gives neat and sharp cuts on the inside parts. This is the best choice if your job needs inner profile graphites for moulding tools. It is steady, reliable, and used by many who need delicate inner shapes with precise detail.

Compare Graphite Inner Profile Cut Machine Features

| Machine Model | Main Use | Key Strength |

| SVI 160-100 | Automatic Inner + Outer | Fast speed, auto system, large projects |

| SVI 60-60 | Outer Cuts | Clean sides, small size |

| SVI 80-80 | Inner Cuts | Fine detail, high accuracy |

Buy Graphite Inner Profile Cut Machine

For good graphite inner profile cut machines, visit VIMFUN. They sell the SVI 160-100 CNC Automatic Graphite Cutting Machine, the SVI 60-60 Graphite Outer Profile Cutting Machine, and the SVI 80-80 Graphite Inner Profile Cutting Machine. On their site, you can read full info, see more models, and pick the right tool for your work. VIMFUN also gives help, service, and support to ensure you use your graphite inner profile cut machine to the best of its ability.

FAQs

- What is the best machine for inner profile graphite cuts?

The SVI 80-80 Graphite Inner Profile Cutting Machine is the best for fine inner cuts and small shapes.

- How can I lower the price of my graphite profile cutting machine?

Pick a model that fits your work size. The SVI 160-100 is suitable for huge jobs at a fair cost, while smaller models are best for light jobs.

- Can I order custom graphite parts instead of buying a machine?

Many shops offer graphite inner profile cutting service, so you can get custom parts made for you.

- What care does the graphite inner profile cut machine need?

Basic graphite profile cut machine maintenance, like cleaning dust, checking tools, and oiling parts, will keep it strong for years.

- Do all machines cut both inner and outer shapes?

Not all. The SVI 60-60 is best for outer cuts, while the SVI 80-80 is for inner detail.