A graphite slicing machine is especially made to cut the graphite with accuracy. There are automated blade adjustment features that help to cut the graphite easily. It is easy to use. These machines are best for tough jobs. These machines are used in various essential sectors. For the accurate cuts you can easily use these machines. Everyone can easily use these machines without errors. And these machines are especially designed to last for a long time.

Benefits of Automated Blade Adjustment

An automated blade change saves both time and effort. It also makes each cut steady and the same without needing extra skill. Graphite Slicing Machine helps you meet industrial graphite slice thickness tolerances and ensures all slices look smooth and even. It also adds safety, speed, and ease to your work since the machine does most heavy tasks. It reduces mistakes, tool wear, and stress for the user while keeping jobs neat and straightforward.

Recommended Machines for Graphite Slicing

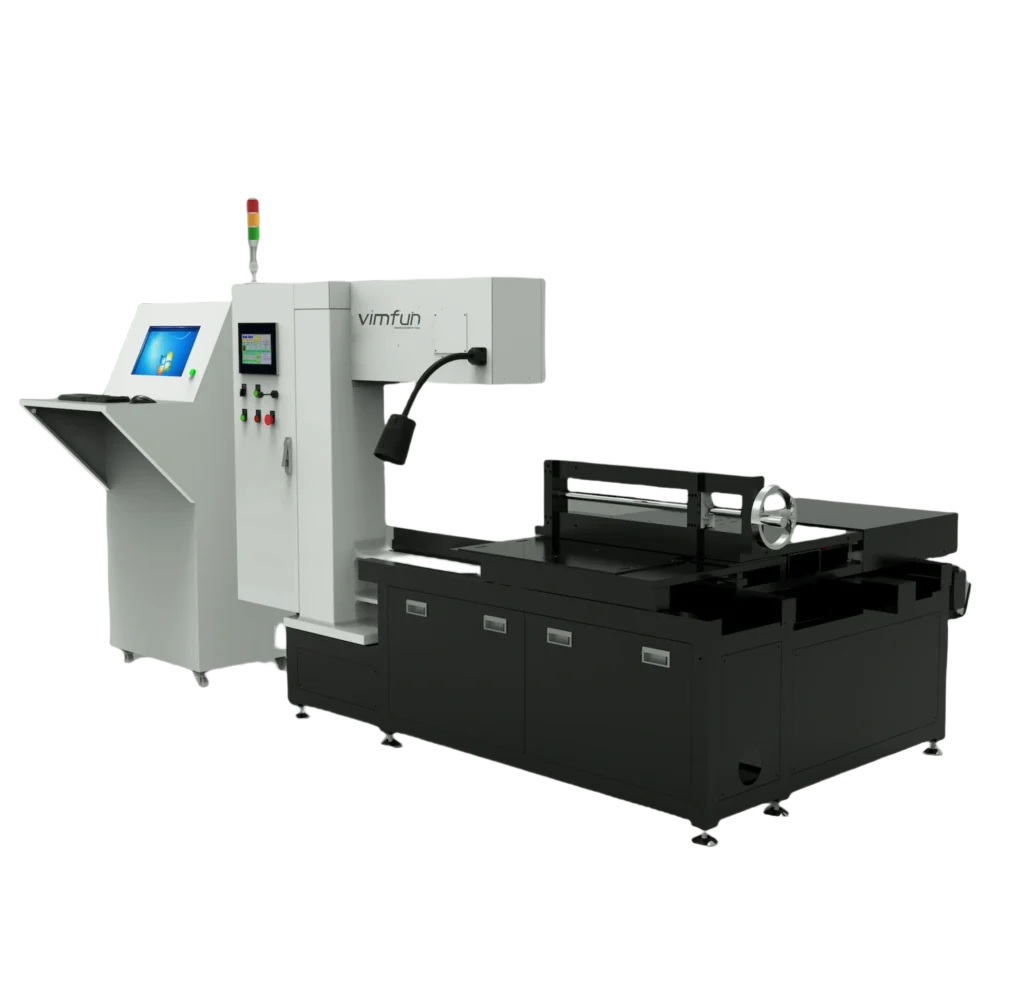

SH 60-60 Horizontal Graphite Cutting Machine

SH 60-60 Horizontal Graphite Cutting machine is suitable for flat and wide blocks, often used simultaneously in large tasks or many parts. It moves steadily for accurate cuts and very smooth faces. It can hold industrial graphite slice thickness tolerances all day. It is strong, simple to run, low cost, and made for extended use and steady work, so you get more value, less trouble, and less downtime.

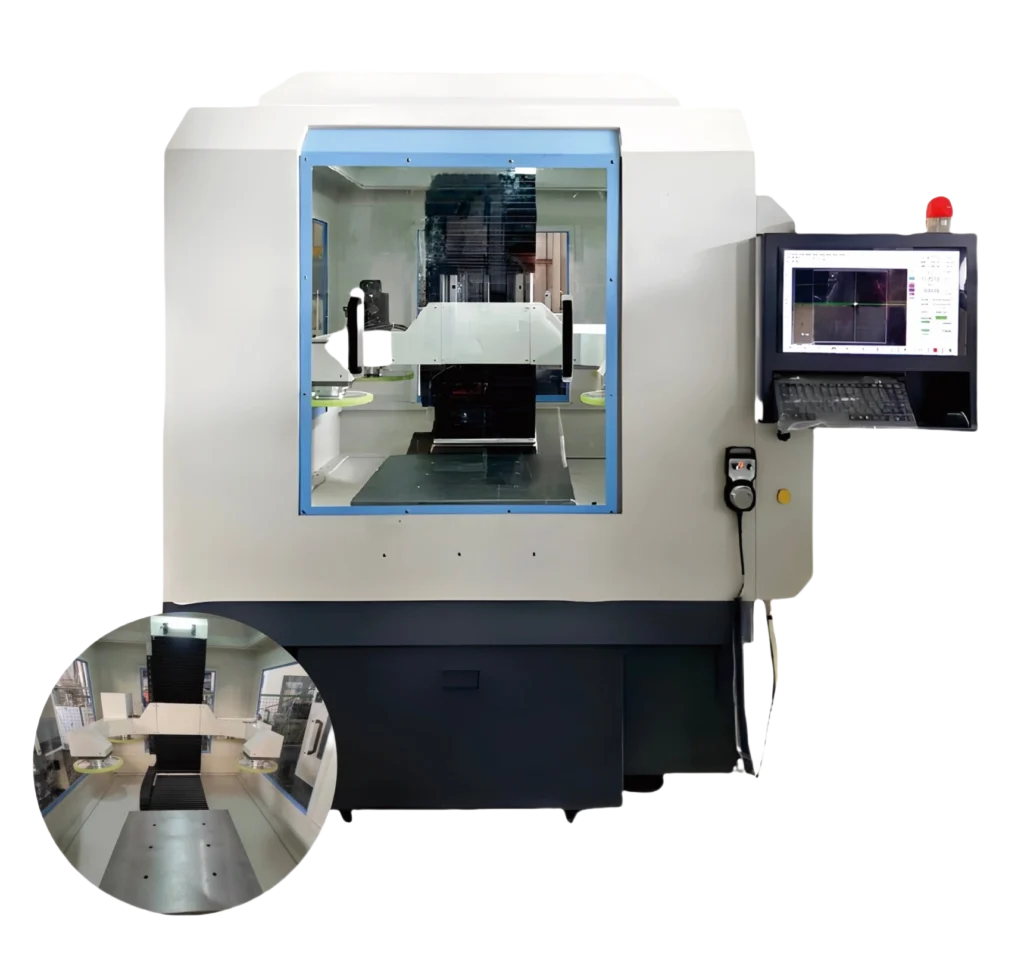

SV 60-60 Vertical Graphite Cutting Machine

SV 60-60 Vertical Graphite Cutting Machine unit is best for tall and narrow blocks. It gives a smooth edge and a fast cut for many shapes and sizes. It is excellent for a CNC graphite slicing machine for EDM electrodes and custom parts. It is easy to load, quick to clean, and safe for new staff and skilled users. Its design helps speed up work and reduce dust for a neat job site.

SVI 60-60 Graphite Outer Profile Cutting Machine

SVI 60-60 Graphite Outer Profile Cutting Machine unit is best for making special forms and outer shapes that standard machines cannot cut well. It slices curves, edges, and outer lines with neat care and smooth results. It is excellent for making battery and EDM parts in many shapes and styles, so you can finish more jobs in less time. It gives clean work for both simple and complex shapes.

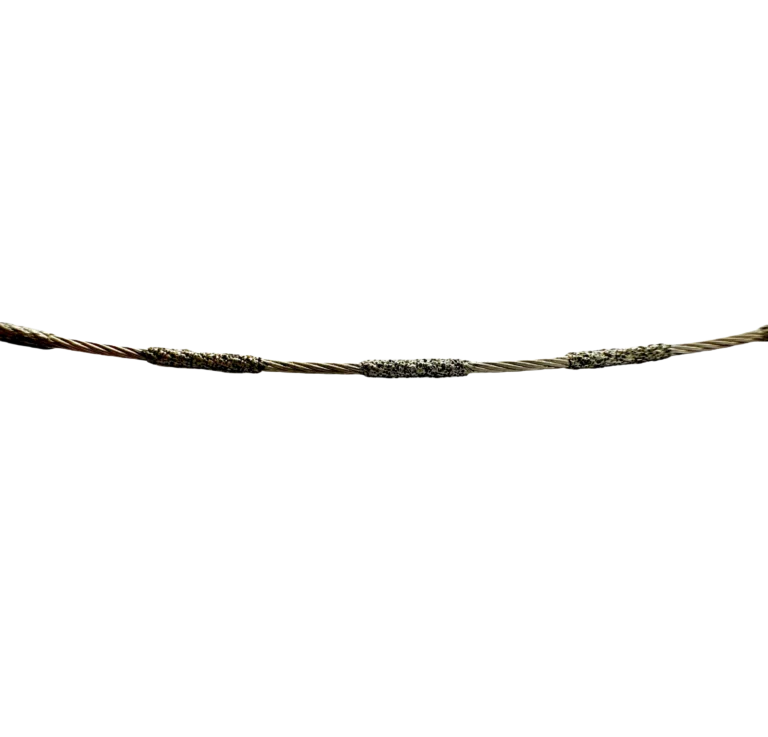

SV 240-40 CNC Diamond Wire Cutting Machine

SV 240-40 CNC Diamond Wire Cutting Machine high-speed model uses strong diamond wire with intelligent drive control. It is a high speed graphite slicing machine for battery anodes and other thin slice parts. It works well for wafer shapes, thin plates, and more. It runs smoothly, cuts fast, keeps waste low, and lasts long even under heavy daily use, so you always get high value and safe work.

Graphite Slicing Machine Parts Table

| Part Name | Use |

| Blade Unit | Cuts graphite neat with smooth edge and less dust |

| Clamp System | Holds block steady so it does not move during cut |

| Dust Control | Keeps work area clean, safe, and clear for all |

| Auto Feed | Moves block at the right pace and keeps cut even |

| Control Panel | Easy to set up, change settings, and adjust fast |

| Safety Guard | Keeps user safe and blocks dust and chips |

Graphite Slicing Vs Cutting Methods

Graphite slicing versus cutting methods shows that slicing is softer, smoother, and gives less waste. Slicing holds the block shape accurately, lowers chip loss, and cuts down dust, so you save time and protect your health. Cutting can be rough with more dust, waste, and extra work to clean up parts later. Knowing this difference helps you pick the best way for your job and save on cost while making safer, cleaner results.

Maintenance Tips

Follow these graphite slicing machine maintenance tips to keep it strong and safe for prolonged use:

- Clean the blade after each use to keep it sharp and ready.

- Check clamps for a tight hold before every job.

- Change filters in dust control often so the air stays fresh and clear.

- Test the auto feed once a week to make sure it runs smoothly.

- Keep the control panel dry and check cables for safe use.

- Oil moving parts are needed to reduce wear and damage.

- Teach staff safe cleanup and check after every workday.

Graphite Slicing Machine Price

The graphite slicing machine price depends on size, speed, parts, and brand. Machines with CNC and auto blade change cost more but give better cuts, faster work, and less waste in the long run. Look for graphite wafer slicing machine manufacturers who offer complete support, spare parts, training, and warranty. This will help you get longer life from your machine and lower cost over time with safer and smoother use.

VIMFUN: for the Best Graphite Slicing Machines

We suggest buying from VIMFUN because they offer many models, spare parts, and full support. Their website has all these models with detailed pages, guides, and clear videos. It also has spare parts and expert help that is fast and simple. Visit VIMFUN to see the SH 60-60, SV 60-60, SVI 60-60, and SV 240-40 models. Their team can guide you to the right choice, share price info, and give setup and care tips.

A good machine makes your job clean, safe, and fast with less waste and stress. Check the precision graphite slicing machine price and see what you need most. Look at VIMFUN for the best deal, clear support, and long-term value so you can focus more on your work and less on your tools.

This graphite slicing tool is right for neat, sharp, and smooth cuts. With the auto blade set, it works smartly, safely, and quick. A strong tool for clean jobs, it saves time, gives precise cuts, and makes work easy. Built to last, it is a tool you can trust.

FAQs

- What is the best blade for graphite slicing?

Use blades with the right graphite slicing blade specifications for your block size, block strength, and slice thickness so you get smooth and neat cuts.

- Can I slice graphite at high speed?

Yes, a high speed graphite slicing machine for battery anodes can do this safely and neatly when set up right.

- How do we keep the slice size the same?

Use machines with auto feed, keep the blade sharp, and often check industrial graphite slice thickness tolerances to stay true and even.

- How often should I do maintenance?

Follow maker steps and do small checks each day and large checks each month to keep your machine safe and strong for extended use.