Connectable Diamond Wire

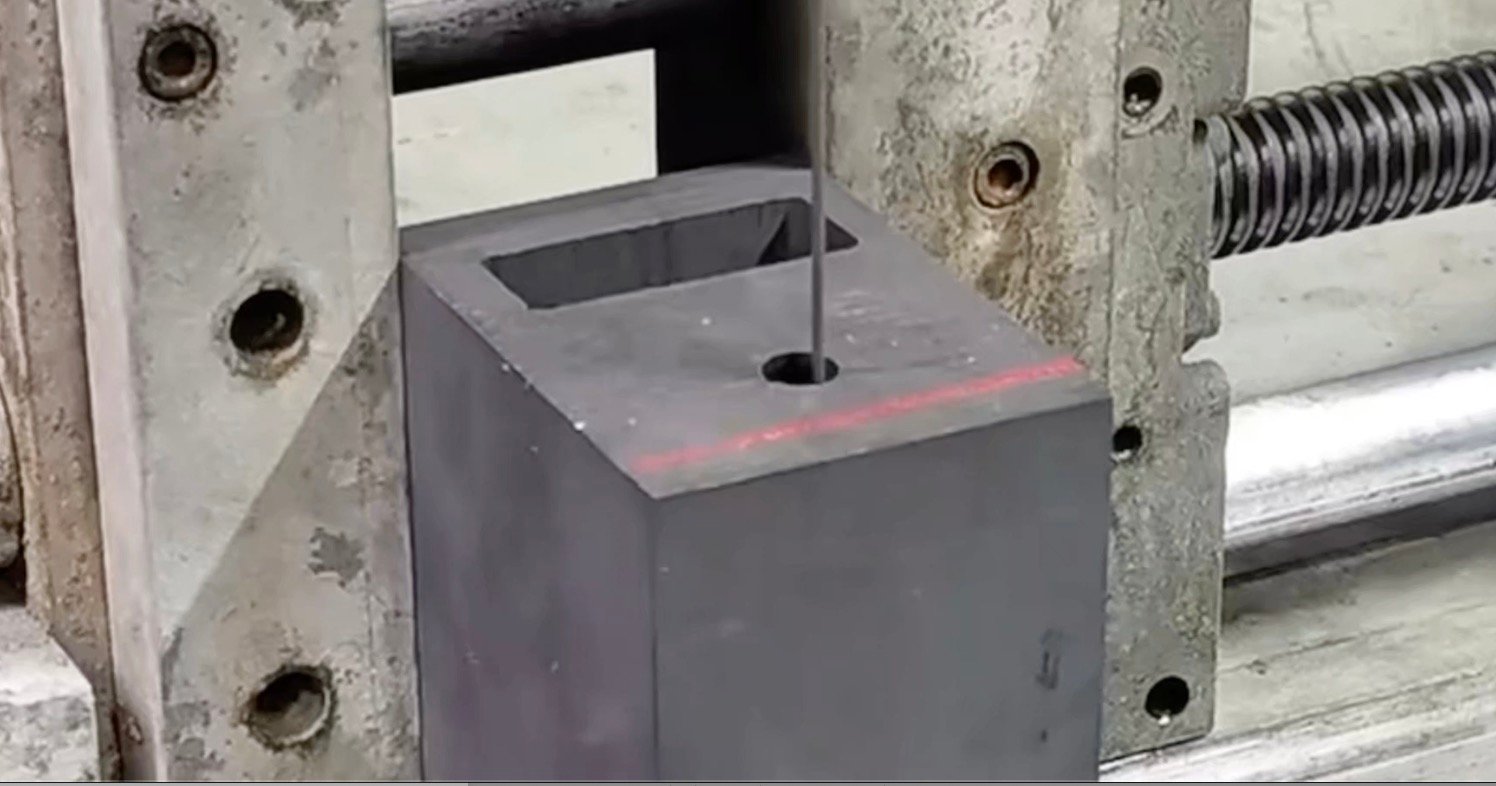

Our connectable diamond wire is a specialized cutting solution for graphite parts that require internal hole or cavity cutting. Supplied with open ends, this wire can be manually inserted through pre-drilled holes in the workpiece, then cut to length and joined on-site using a dedicated splicing tool.

Once connected, it forms a closed-loop diamond wire, suitable for use in endless diamond wire cutting machines. This wire uses a segmented electroplated coating, providing excellent chip clearance and stability — especially useful in tight or dust-heavy inner cutting conditions.

⚙️ Key Features

Open-Ended Structure for On-Site Looping

Allows users to feed wire through enclosed or narrow internal holes before closing the loop.Manual Length Adjustment

Wire can be cut on-site to match any required loop length for custom machines or tool paths.Segmented Electroplated Coating

Improves chip evacuation and reduces resistance during inner cavity cutting.Heavy-Duty Wire Core

Wire diameters range from 1.5 mm to 2.5 mm, providing high tension stability and durability.Compatible with Insertion-Required Cutting Jobs

Ideal for parts that cannot be cut using pre-closed wire loops.

CONNECTABLE WIRE TECHNICAL SPECIFICATION

| Parameter | Value |

|---|---|

| Structure | Open-Ended Diamond Wire (connectable) |

| Coating Type | Segmented Electroplated, Bare Grit |

| Wire Diameter Range | 1.5 mm – 2.5 mm |

| Grit Size | 80# (optional) |

| Length | Supplied in bulk, user-cuttable |

| Closing Method | On-site fusion or mechanical joining |

| Recommended Cutting Mode | Dry or semi-dry |

| Application Type | Inner hole or internal cavity cutting in graphite materials |

Typical Applications

Cutting internal holes or chambers inside large graphite blocks

Situations where standard endless loops cannot be pre-inserted

Graphite crucibles, tubes, or chambers with internal machining paths

R&D setups or special tool access configurations

Low-volume or custom-size graphite structures

Usage Instructions

Pre-drill or identify a small through-hole in the graphite workpiece

Feed the open-ended wire through the hole manually

Cut the wire to match your machine’s loop length

Use a splicing tool or joining device to connect both ends

Install and tension the closed loop on the wire saw as usual

We also supply wire joining tools upon request.

Packaging & Delivery

Supplied in coils or straight lengths

Length markings available on request

Joining tool kits available separately

Lead time: 5–7 business days

THE APPLICATION OF THIS DIAMOND WIRE

Customer Testimonials

Frequently Asked Questions

What materials can I cut with an endless diamond wire saw?

How can I use an endless diamond wire loop saw?

You need a wire saw machine which can tention the cutting wire.buy one or manully make one.

What is the serving life of an endless diamond wire saw?

What is the wire length?

If the wire breaks, can it be reconnected and used again?

How Can I buy the diamond wire loop?

Let us konow your required wire dia and wire length, we will send the diamond wire loop to your location by DHL or Fedex.