Diamond Wire for Graphite Cutting

Our full electroplated diamond wire is a high-precision endless loop wire specifically engineered for graphite cutting applications. It features a uniform diamond coating along the entire wire, with exposed diamond particles (open-grit structure) that enhance sharpness and cutting consistency.

Unlike traditional wire saws that use spooled wire, this closed-loop wire is designed exclusively for endless diamond wire cutting machines, offering high-speed performance with minimal kerf and smoother surface finish

⚙️ Key Features

Endless Loop Design

A closed wire loop that runs in one direction — stable, efficient, and compatible with endless wire machines only.Bare Grit Electroplated Coating

Diamond grains are exposed directly on the surface (not embedded), providing superior sharpness and cleaner slicing.Precision Surface Quality

Enables extremely smooth cutting surfaces, ideal for high-purity graphite parts.Fine Wire Compatibility

Available in wire diameters as small as 0.3 mm, allowing for narrow kerf widths and delicate workpiece processing.Customizable Lengths

Wire loops are manufactured to match your machine specifications. Tell us your model, and we’ll deliver the right fit.

ELECTROPLATED DIAMOND WIRE LOOP TECHNICAL SPECIFICATION

Specifications

Specifications

| Parameter | Value |

|---|---|

| Structure | Endless (Closed Loop) |

| Coating Type | Full Electroplated, Bare Grit |

| Wire Diameter Range | 0.3 mm – 1.0 mm |

| Grit Sizes Available | 80# / 100# / 120# (others on request) |

| Length | Custom per machine model |

| Recommended Cutting Mode | Dry or semi-dry |

| Suitable Materials | Graphite blocks, plates, EDM blanks, battery graphite |

Typical Applications

Typical Applications

High-precision slicing of graphite blocks and slabs

Production of graphite electrodes, battery anodes, and mold blanks

CNC profile cutting requiring smooth surface finish

Cleanroom or high-purity graphite applications

R&D labs and semiconductor graphite component preparation

Equipment Compatibility

Equipment Compatibility

This wire is compatible with all Vimfun endless diamond wire cutting machines, including:

SV Series (vertical cutters)

SH Series (horizontal cutters)

SVI Series (profile cutters)

SVR Series (rotary cutters)

We also supply custom loops for non-Vimfun machines. Contact us with your required loop length.

Packaging & Delivery

Packaging & Delivery

Vacuum-sealed in dust-free packaging

Each wire labeled with diameter and loop length

Typical lead time: 5–7 working days

Bulk quantity and OEM available

3 TYPES OF DIAMOND CUTTING LOOPS

https://www.youtube.com/watch?v=R6Ba4VVPP5A

The difference between different Electroplated Diamond Wire Loop

- Full-Coated Electroplated Diamond Wire Loop:

- The cutting wire of full-coated wires is relatively thin, with the thinnest being 0.3 mm.

- These wires are particularly advantageous in cutting hard and brittle materials such as quartz, silicon rods, optical glass, and rare metals.

- These wires are particularly advantageous in cutting hard and brittle materials such as quartz, silicon rods, optical glass, and rare metals.

- The fully coated wire has a large number of diamond abrasives all over the surface of the cutting wire, so it has a strong cutting force. Therefore, it has obvious advantages when cutting materials with small chip removal and high hardness.

- Our fully coated wire not only has a high abrasive density, but also uses a mixture of raw diamonds and crushed diamonds, making the cutting wire both sharp and wear-resistant. Therefore, the service life is longer than others.

- Segmented-Coated Electroplated Diamond Wire Loop:

- The thinnest segmented-coated wire is 0.8mm.

- The segmented coating creates a lot space on the surface of the cutting wire, which can accommodate a large amount of material debris during the cutting process. As the cutting wire moves, it carries and discharges the debris, significantly increasing its chip removal capacity.

- These wires excel in cutting materials like graphite and corrugated paper, which are not very hard but produce a lot of dust.

- Thread- Coated Electroplated Diamond Wire Loop:

- The thinnest thread-coated wire is 0.5 mm.

- The threaded coating creates spiral gaps on the surface of the diamond wire, which can accommodate a large amount of material debris during the rotation of the cutting wire. As the cutting wire moves, it carries and discharges the debris, significantly increasing its chip removal capacity.

- These wires excel in cutting materials like graphite and corrugated paper, which are not very hard but produce a lot of dust.

Additionally, full-coated Electroplated Diamond Wire Loop are widely used in materials processing where cutting fluid can be applied, whereas segmented-coated and thread- coated diamond wires are mainly used in dry cutting processes.

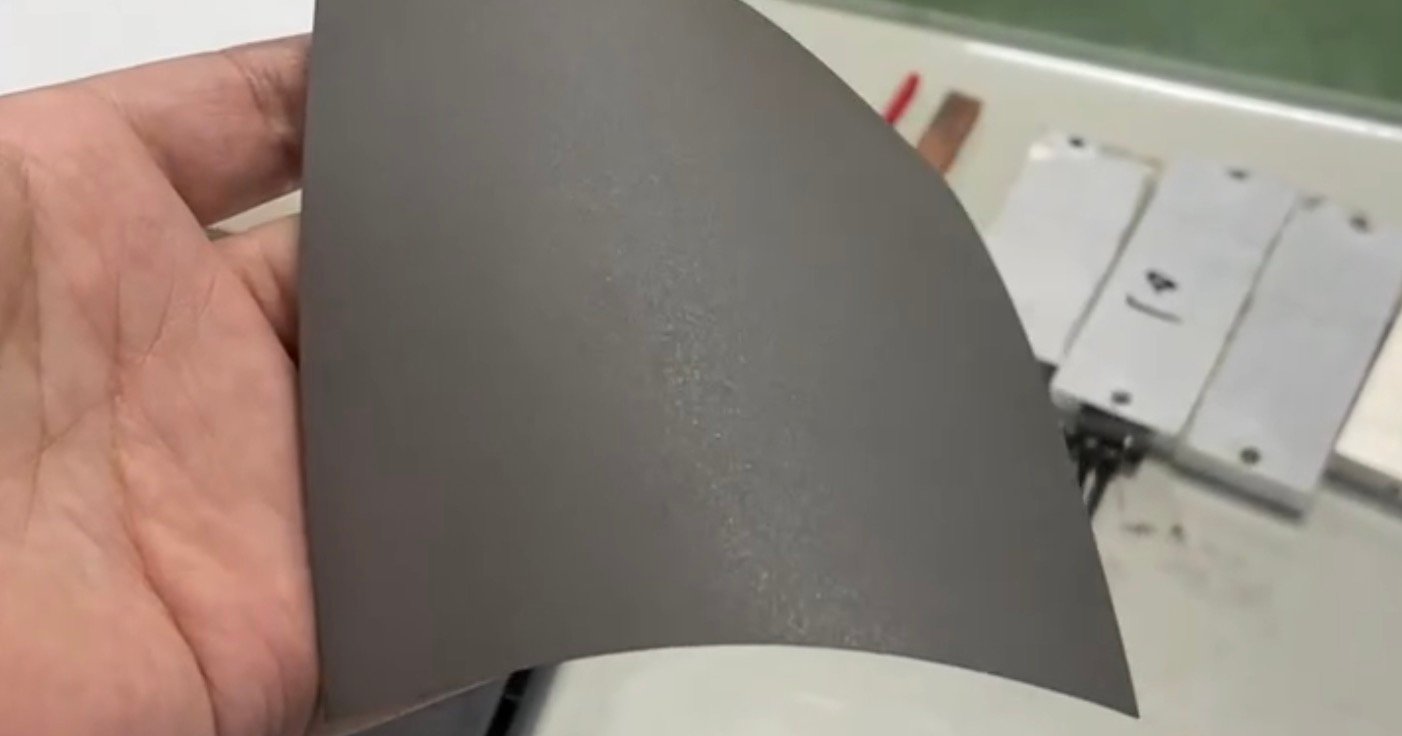

HOW ELECTROPLATED DIAMONDWIRE LOOP LOOKS

THE MATERIAL ELECTROPLATED DIAMOND WIRE LOOP CUT

Porous Metal

Electroplated Diamond Wire Loop

Endless diamond wire can cut porous metal fact and clean withut damage the material structure

Graphite

Electroplated Diamond Wire Loop

It’s widely used to cut differnt size graphite products such as graphite boat, Electrodes,Molds, Industrial Furnace Components, Graphite Crucibles, Battery Anodes…

Carbon-Carbon Composites

Electroplated Diamond Wire Loop

Our endless wire saw can cut carbon- carbon material without delamination,

Industrial Ceramic

Electroplated Diamond Wire Loop

The cutting speed of green ceramics is very fast, and the cutting angle of special shapes is also perfect.

Corrugated Paper Board

Electroplated Diamond Wire Loop

This machine can cut Corrugated paper very fast and maintain paper structure, widly used to cut cat scrath boad.

Customer Testimonials

Frequently Asked Questions

What materials can I cut with an endless diamond wire saw?

How can I use an endless diamond wire loop saw?

You need a wire saw machine which can tention the cutting wire.buy one or manully make one.

What is the serving life of an endless diamond wire saw?

What is the wire length?

If the wire breaks, can it be reconnected and used again?

How Can I buy the diamond wire loop?

Let us konow your required wire dia and wire length, we will send the diamond wire loop to your location by DHL or Fedex.

Specifications

Specifications Typical Applications

Typical Applications Equipment Compatibility

Equipment Compatibility Packaging & Delivery

Packaging & Delivery