SV 240-40

The SV 240-40 is a high-precision CNC diamond wire cutting machine engineered specifically for cutting graphite boats and elongated graphite components. Designed to meet the demands of photovoltaic, semiconductor, and high-temperature processing industries, this machine offers stable, burr-free slicing of long graphite structures with exceptional surface quality.

Key Features of SV 240-40

Purpose-Built for Graphite Boats

Engineered specifically for long and thin graphite structures, including boats, carriers, and trays used in semiconductor and PV applications.Endless Diamond Wire Cutting

Utilizes a high-speed endless diamond wire system for stable, smooth, and chip-free cutting of fragile graphite materials.Customizable Cutting Range

The cutting dimensions and fixturing system can be tailored to fit graphite boats of various lengths and widths.Low Kerf Loss, High Precision

Achieves clean slicing with kerf widths as narrow as 0.4 mm, minimizing material waste and reducing edge damage.Vacuum Chuck Clamping System

Uses a high-hold vacuum platform to securely fix the graphite boat during cutting.

This method allows the entire material length to be utilized — no tail stock, no clamps in the cutting zone — meaning zero material waste.Easy Loading of Elongated Workpieces

Side-loading platform allows easy placement and alignment of long graphite parts using cranes or rollers.CNC-Controlled Automation

Ensures repeatable cutting paths and programmable parameters for consistent results, batch after batch.- Ultra-Low Cutting Force

Abrasive cutting method reduces mechanical stress on delicate edges, preventing chipping or microfractures. - Simple Slice-Only Configuration

This machine is optimized for straight slicing only, ensuring maximum mechanical stability and throughput for high-volume production.

SV240-40 TECHNICAL SPECIFICATION

| No. | Name | Specification |

| 1 | Maximum Workpiece Length (mm) | 2400 |

| 2 | Maximum Workpiece Width (mm) | 400 |

| 3 | Maximum Workpiece Height (mm) | 400 |

| 4 | Worktable X-Axis Travel (mm) | 2500 |

| 5 | Worktable Y-Axis Travel (mm) | 500 |

| 6 | Maximum Diamond Wire Speed (m/s) | 70 |

| 7 | Minimum Feed Increment X-Axis (mm) | 0.01 |

| 8 | Minimum Feed Increment Y-Axis (mm) | 0.01 |

| 9 | Repeat Positioning Accuracy X-Axis (mm) | 0.01 |

| 10 | Repeat Positioning Accuracy Y-Axis (mm) | 0.01 |

| 11 | Total Power Consumption (kW) | 4 |

| 12 | Power Supply | 380V 50Hz |

| 13 | Machine Size(mm) | 5100*1900*2150 |

| 14 | Machine Weight(kg) | 3500 |

| 15 | Air Pressure(MPa) | 0.5-0.8 |

See the SV 240-40 in Action at Customer Sites

Comparison Between Diamond Band Saw and a Single Diamond Wire Saw

Aspect | Diamond Band Saw | Endless Diamond Wire Saw |

Cutting Mechanism | Utilizes a continuous loop of diamond-coated band as the cutting tool. | Employs a continuous loop of diamond-coated wire as the cutting tool. |

Cutting Speed | Generally slower cutting speed due to the movement of the band. | Faster cutting speed due to the continuous linear motion of the wire. |

Kerf Width | Typically has a wider kerf width, leading to more material wastage. | Minimizes kerf width, resulting in minimal material wastage. |

Cut Surface Quality | May require additional polishing steps to achieve a smooth finish. | Simultaneously cuts and polishes, ensuring a smooth and shiny surface. |

Versatility | Suitable for basic cuts and straight lines. | Highly versatile, suitable for complex shapes and intricate designs. |

Precision | Moderate precision; may not achieve intricate designs accurately. | Offers high precision, ideal for intricate graphite components. |

Material Efficiency | Can be less material-efficient due to wider cuts. | Maximizes material efficiency with narrow cuts. |

Dust Generation | Generates more dust, potentially requiring dust extraction systems. | Produces minimal dust, contributing to a cleaner working environment. |

Application | Mainly used for simpler cutting tasks | Ideal for various cutting needs, especially intricate graphite parts. |

Ideal Use Case | Basic straight cuts in graphite. | Precision cuts, intricate designs, and complex graphite components. |

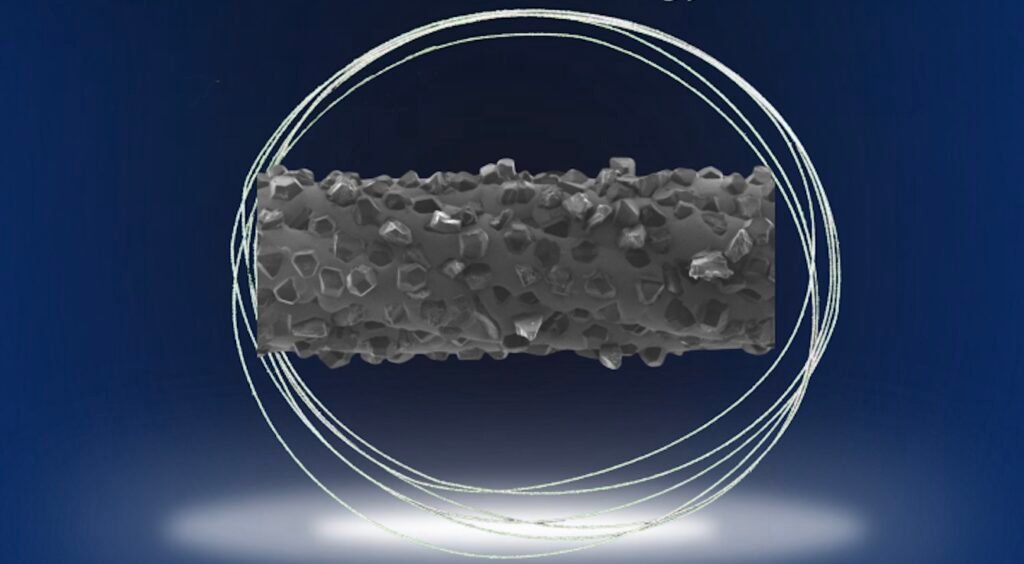

COMPARISON OF THE CUT SURFACE EFFECT

TYPICAL APPLICATIONS OF THIS GRAPHITE BOAT CUTTING MACHINE

Photovoltaic Industry (Solar Crystal Growth)

Graphite boats are widely used as carriers in silicon ingot pulling and wafer sintering processes.

The SV 240-40 enables precise cutting of these long graphite structures, ensuring dimensional consistency, flatness, and minimal kerf loss — all critical for efficient crystal growth operations.

Hot Zone & Thermal Insulation Systems

Many high-temperature systems, such as vacuum furnaces and MOCVD reactors, use custom-cut graphite trays or fixtures.

SV 240-40 offers accurate, repeatable slicing of these parts with clean edges, reducing post-processing and improving equipment compatibility.

Semiconductor Packaging & Furnace Systems

In the semiconductor industry, graphite boats are used to hold wafers or substrates during thermal processing.

Our machine provides burr-free slicing of graphite carriers used in diffusion, annealing, and oxidation furnaces, preserving surface quality and structural integrity.

Custom Graphite Component Production

For machining centers or OEM suppliers, this machine is ideal for batch slicing of various graphite boat formats — whether for solar, semiconductor, or new material pilot lines — delivering reliable performance with low dust and easy operation.

WHY CHOOSE US

High-Speed Endless Wire Cutting

High-Rigidity Cast Structure

High-Precision Guide Rails and Ball Screw

Automatic Constant-Tension System

Micron-Level Feed Control

User-Friendly Smart Interface

Fully Enclosed Protective Design (Optional)

Low Maintenance & Cost Efficiency

Modular Design

Low Maintenance & Cost Efficiency

Automatic Lubrication System

Customer Testimonials

Frequently Asked Questions

What is the maximum thickness the machine can handle for cutting?

What is the difference between this wire saw and BAND SAW?

The cutting speed would be similar, but wire saw’s cut surface quality is far more better. and the kerf loss is smaller.