Graphite inner profile cutting machines are very useful in many industries. They help to cut graphite parts into exact shapes. These machines are used in factories that make molds, electrodes, and technical ceramics. They save time and make work easier. Using a CNC graphite cutting machine or a graphite wire cutting machine helps workers make parts faster. These machines are strong, safe, and accurate.

Why Graphite Inner Profile Cutting Machines Are Important

Graphite inner profile cutting machines are essential for producing graphite parts. They cut inside holes, slots, and molds very accurately. A graphite inner hole cutting machine can make perfect holes without breaking the graphite. Industries such as electronics, automotive, and aerospace need these machines. They help reduce mistakes and save material. Workers can make many parts quickly with the right machine.

Types of Graphite Cutting Machines

There are many types of graphite cutting machines. CNC graphite cutting machines are computer-controlled. They give exact cuts every time. Graphite wire cutting machines are good for cutting small or thin shapes. Graphite slot cutting machines help create grooves in parts. Graphite mold cutting machines produce high-quality molds for various applications. EDM electrode graphite cutting machines are used to make electrodes for electrical discharge machining. Technical ceramics cutting machines safely cut very hard materials.

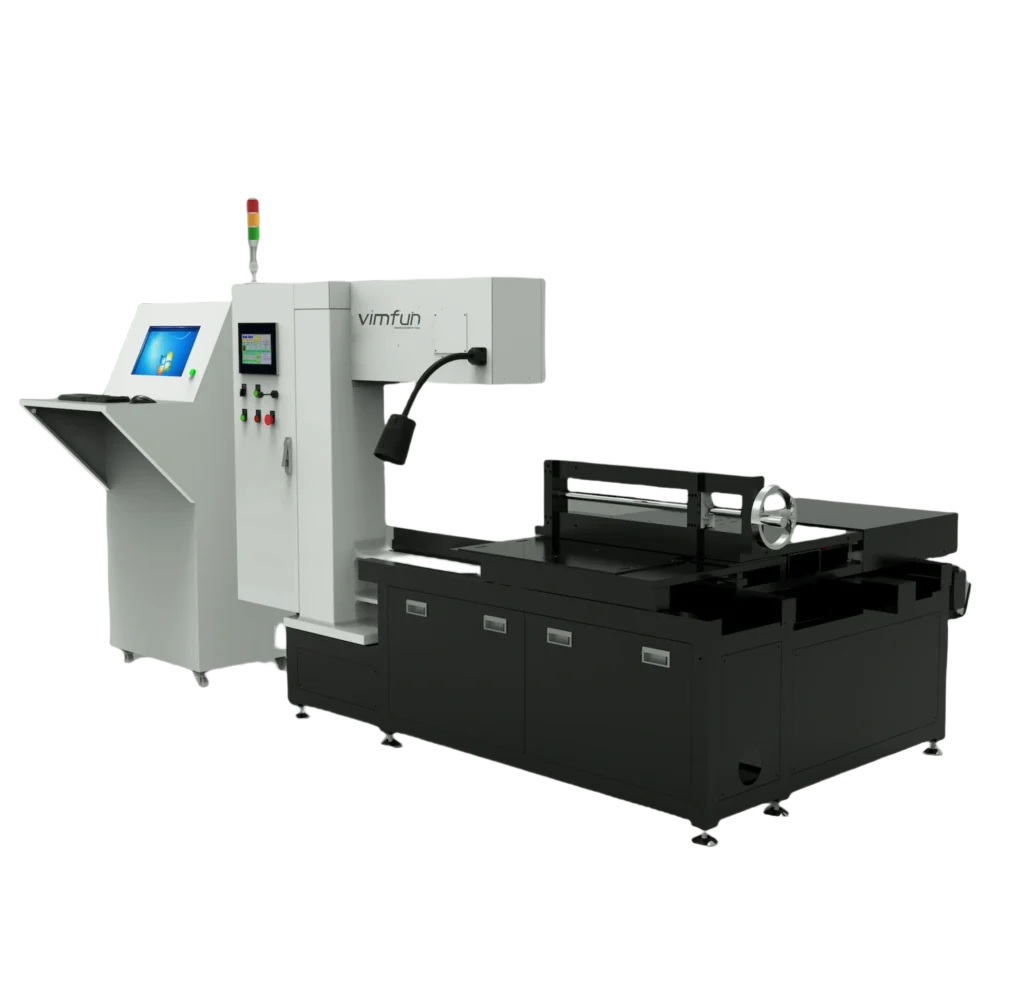

SVI 80-80 Graphite Inner Profile Cutting Machine

The SVI 80-80 Graphite Inner Profile Cutting Machine is very strong and accurate. It is perfect for cutting inner shapes in graphite parts. It works for molds, slots, and holes. It is very useful in factories that make electrodes or technical ceramics.

Features:

- CNC control for exact cutting

- Works with wire cutting and slot cutting

- Good for EDM electrode cutting

- Easy to use

The SVI 80-80 is very reliable. It can work for many hours without problems. It helps make parts quickly and without mistakes.

Benefits of CNC Graphite Cutting Machines

CNC graphite cutting machines are very useful in factories. They are computer-controlled and make exact cuts. These machines reduce human mistakes. They are very good for creating many parts of the same size and shape. They save time and material. CNC machines are also safe and easy to use. Workers can make complicated parts quickly.

Advantages of Graphite Wire Cutting Machines

Graphite wire cutting machines use a thin wire to cut graphite. They are very good for making small and detailed shapes. These machines cut smoothly without breaking the graphite. Factories that make molds or inner holes use these machines. They are fast and make accurate cuts every time. Combining wire cutting with CNC control gives the best results.

Graphite Inner Hole Cutting Machines and Their Uses

Graphite inner hole cutting machines make holes inside graphite parts. These holes are very exact and smooth. They are used in EDM electrodes, molds, and technical ceramics. Factories need these machines to make high-quality parts. Using inner hole cutting machines helps reduce errors and save material. They make the work easier and faster.

Graphite Slot and Mold Cutting Machines

Graphite slot cutting machines are used to make grooves in graphite parts. Graphite mold cutting machines make perfect molds for industry. These machines are very accurate. They help factories save material and time. Cars, airplanes, and electronic parts are often made with these machines. They make parts that are all the same size and shape.

EDM Electrode Graphite Cutting Machines

EDM electrode graphite cutting machines make graphite electrodes. These are used in electrical discharge machining. The machines make very smooth surfaces and exact dimensions. Factories that need high precision use these machines. They help to make parts quickly and without errors.

Endless Diamond Wire Saw and CNC Diamond Wire Saw Machines

Endless diamond wire saw machines cut very hard materials. CNC diamond wire saw machines also cut hard materials, but are computer-controlled. They make smooth and exact cuts. They are good for large industrial work. Factories use these machines to cut graphite and technical ceramics. They are safe, fast, and precise.

Technical Ceramics Cutting Machines

Technical ceramics cutting machines are used to cut very hard materials, such as ceramics and graphite. They are strong and accurate. Factories that make technical parts for electronics, aerospace, and medical use need these machines. Using them with graphite inner profile cutting machines gives the best results. Parts come out smooth and perfect.

How to Choose the Right Graphite Cutting Machine

Choosing the right machine is very important. CNC machines are well-suited for automation and repetitive cutting. Wire cutting machines are good for detailed work. Diamond wire saws are best for hard materials. Factories often use more than one machine. This helps them make parts faster and better. Choosing the right machine saves money and reduces waste.

Maintenance and Safety Tips

Graphite cutting machines last longer when well-maintained. Clean machines after use. Check wire tension on wire-cutting machines. Update software in CNC machines. Always wear safety gear when working. Follow all safety rules. This keeps workers safe and machines working well.

Get Your Graphite Inner Profile Cutting Machine Today

Need a good graphite inner profile cutting machine? Vimfun offers strong and easy-to-use machines like the SVI 80-80. They cut graphite quickly, safely, and smoothly. These machines are great for molds, holes, slots, and electrodes. Small workshops or large factories can use them to save time and make parts right the first time. Don’t wait! Contact Vimfun today and get the right graphite cutting machine for your work.

Graphite inner profile cutting machines are very useful for working with graphite and ceramics. Machines like the SVI 80-80 cut fast, safely, and correctly. The right machine saves time and material and lasts a long time.

FAQs

- What is a graphite inner profile cutting machine?

It is a machine that cuts graphite into holes, slots, or shapes.

- Why do factories use these machines?

They make work faster, safer, and more correct.

- What is the SVI 80-80 machine?

It is a strong and easy machine for cutting graphite parts.

- What kinds of graphite cutting machines are there?

There are CNC, wire-cutting, slot-cutting, mold-cutting, and diamond-saw machines.

- How do these machines help factories?

They save time, save material, and make smooth parts.

- How should I take care of a graphite cutting machine?

Clean it, check wires, follow safety rules, and use it carefully.