Finding a reliable Horizontal graphite cutting machine manufacturer is crucial for factories and workshops that work with graphite. A trusted manufacturer produces strong, secure, and long-lasting machines. Blocks of graphite are precisely cut into smooth shapes using these machines. They help to time and reduce waste. Choosing a good Horizontal graphite cutting machine manufacturer also means you get help, spare parts, and service when you need it. Many companies now make easy-to-use, not too expensive machines.

Choose a Horizontal Graphite Cutting Machine Manufacturer

A trusted Horizontal graphite cutting machine manufacturer gives machines that work well for years. These machines can cut big graphite blocks safely and quickly. They use strong parts and smart designs to make cutting easier. A good manufacturer also teaches users how to use the machine correctly. They provide repair and support to keep the machines working. As a result, manufacturers can complete tasks more quickly and save money on repairs.

Features of a Horizontal Graphite-Cutting Machine

Modern machines from a professional Horizontal graphite cutting machine manufacturer have many useful features. They use diamond wires to cut graphite very cleanly. You can change the speed and move the wire smoothly. The machines are stable and do not shake. They save graphite and cut it exactly how you want. These machines are easy to run and need less maintenance. They are a smart choice for any factory seeking fast, safe cutting.

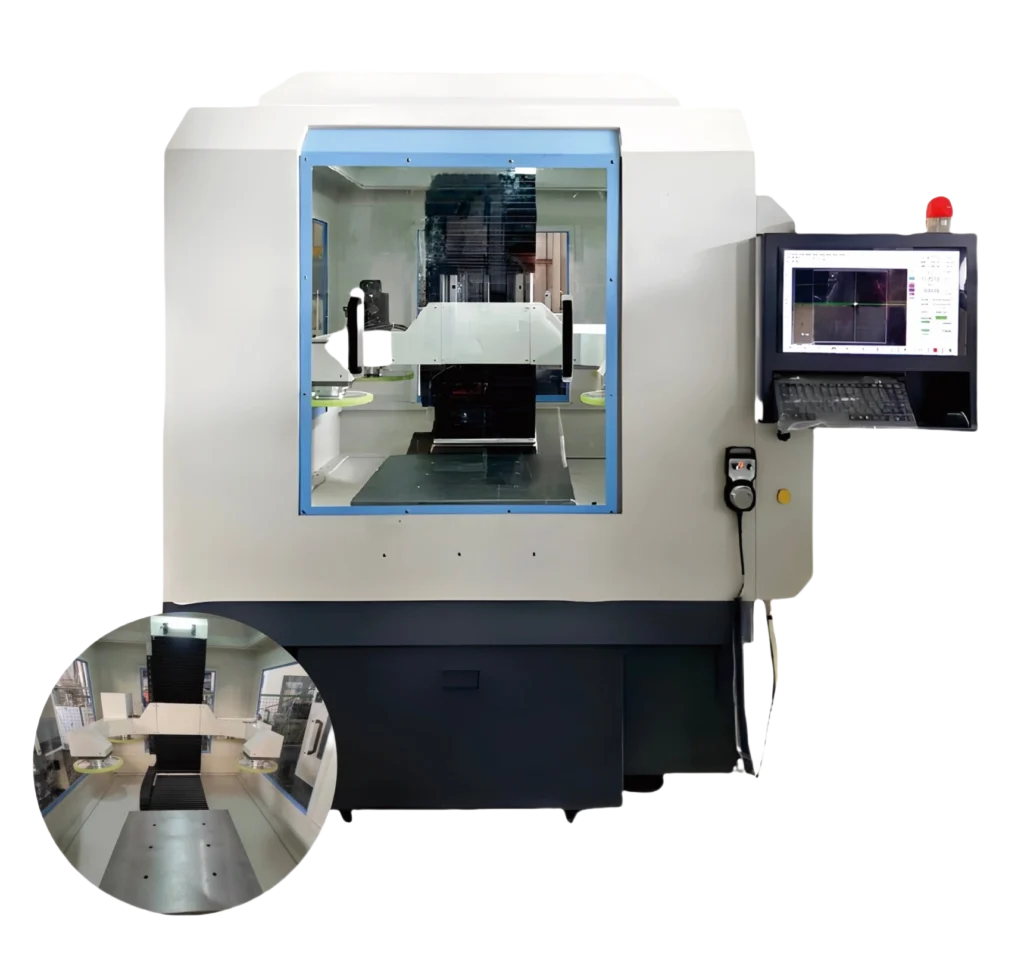

SH 60-60 Horizontal Graphite Cutting Machine

The SH 60-60 Horizontal graphite cutting machine manufacturer is a great machine for cutting graphite blocks. It is strong, accurate, and easy to use.

- Uses Diamond Wire Graphite-Cutting Machine for smooth cuts

- Can cut large graphite blocks with little waste

- Works as a Graphite Block Cutting Machine and a Graphite Slab Cutting Machine

- Runs well and does not need much maintenance

This machine is perfect for small and large factories. It is simple to use, takes up less space, and helps workers cut graphite faster. The SH 60-60 saves time and makes sure cuts are clean and correct.

Uses of Horizontal Diamond Wire Saws

A Horizontal Diamond Wire Saw is very helpful for cutting graphite. It can cut blocks, slabs, and molds. The machine cuts quickly and precisely. Companies use it to make graphite parts for batteries, electrodes, and other products. Using this saw reduces mistakes and saves material. It is very useful for factories that need to cut many blocks every day.

Why a Graphite Slicing Machine is Useful

A Graphite Slicing Machine helps cut graphite into thin and even slices. It works quickly and saves labor. The machine can handle many blocks at once. It keeps the graphite surface smooth and reduces waste. Using a slicing machine makes workers’ work easier. It also helps factories produce high-quality graphite components without spending too much.

Graphite Wire Saw Machine for Factories

A Graphite Wire Saw Machine is strong and made for heavy work. It can easily cut thick graphite blocks and molds. The machine is good for factories that need to cut many pieces every day. It gives exact results and uses less graphite. A wire saw machine is safe and simple to run. It also lasts long and requires few repairs.

How to Choose a Graphite Block Slicing Machine

Picking the right Graphite Block Slicing Machine is very important. Look for a machine that is fast and accurate. It should be strong and last for years. A good slicing machine can handle a wide range of block sizes. It works smoothly and saves money on repairs. Choosing a reliable machine helps factories cut graphite without mistakes and complete work faster.

Benefits of Industrial Graphite Cutting Equipment

Industrial Graphite Cutting Equipment makes cutting graphite easier and faster. These machines can cut large blocks with exact shapes. They reduce waste and create smooth surfaces. Factories that use industrial cutting machines save time and money. These machines help workers finish large jobs without stress. They are very useful for modern factories that need high-quality graphite pieces.

Uses of Graphite Mold Cutting Machine

A Graphite Mold Cutting Machine is needed to make graphite molds. These molds are used in metal casting and electronics. The machine cuts molds exactly and cleanly. It reduces mistakes and waste. Factories that use mold cutting machines save money and work faster. The machine is easy to run and lasts a long time. It is a smart choice for companies making graphite parts.

Advantages of Graphite Slab Cutting Machine

A Graphite Slab Cutting Machine cuts graphite blocks into thin slabs. It makes even and smooth pieces. The machine works fast and saves labor. It reduces waste and makes production easier. Factories can use it every day without problems. The machine is safe and simple to operate. It is very helpful for companies that need many graphite slabs for their work.

Trusted Horizontal Graphite Cutting Machine Manufacturer

Get a cutting graphite machine from Vimfun. We are a trusted horizontal graphite cutting machine manufacturer. Our machines are strong, safe, and very easy to use. They cut graphite blocks, slabs, and molds clean and fast. Whether you have a small shop or a big factory, Vimfun machines save time and material. Try our SH 60-60 Cutting Machine for smooth and simple cutting. It makes perfect cuts every time. Don’t wait—visit Vimfun now to get the right machine for your work. Cutting graphite has never been so easy!

A trusted horizontal graphite cutting machine manufacturer is good for any factory. Machines like the SH 60-60 are strong and easy to use. They save time, waste less, and make cutting graphite simple.

FAQs

- Why should I choose a trusted manufacturer?

A trusted maker provides strong, safe, and easy-to-use machines, with help available if needed.

- What is the SH 60-60 machine?

The SH 60-60 is a strong, simple machine that cuts graphite quickly and cleanly.

- Can small workshops use these machines?

Yes, small shops and big factories can use them to save time and materials.

- What types of cutting machines are used for graphite?

Diamond wire saws, slicing machines, mold cutters, and slab cutters are used.

- How do these machines help factories?

They make cutting easy, fast, and correct while saving money and graphite.