Products

SHINE High Quality, Good Products

Cut Faster and Better with Us

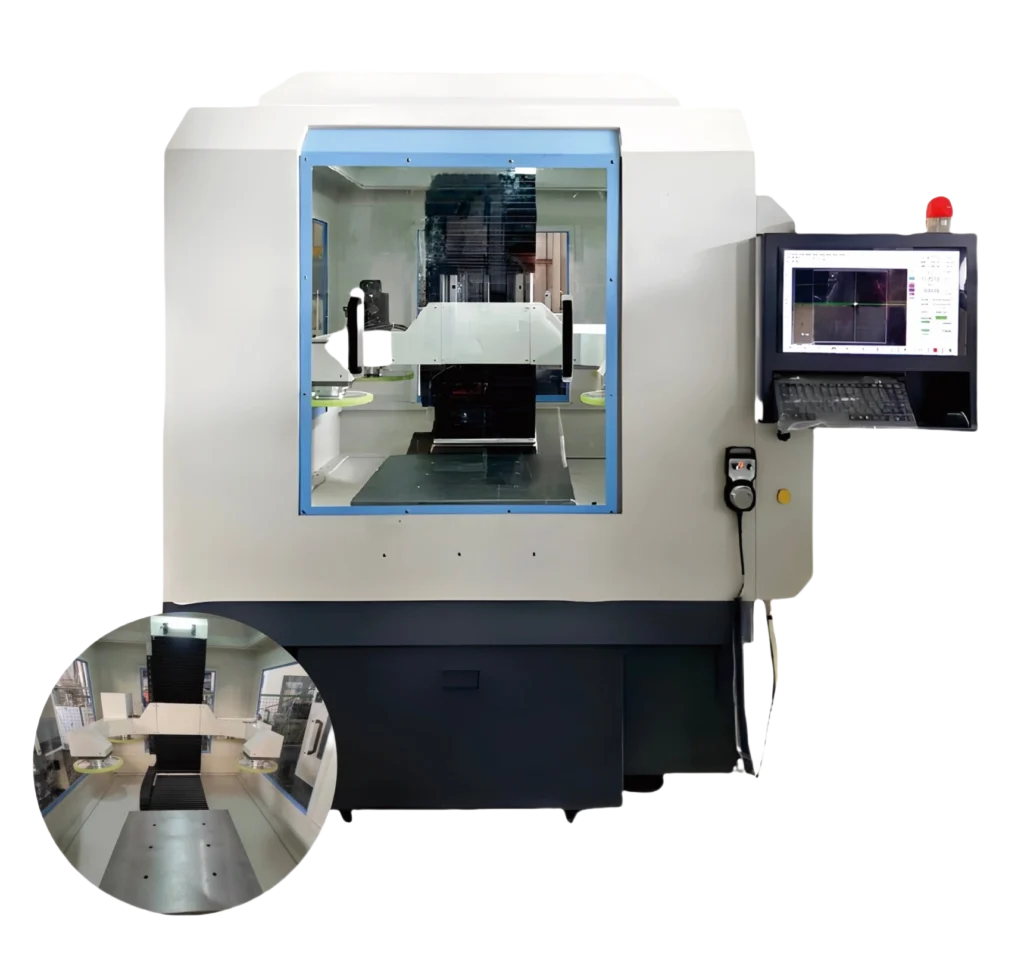

A Horizontal Graphite Cutting Machine is a specialized cutting system designed to process graphite blocks in a horizontal orientation. Unlike vertical systems where the wire moves top-down, horizontal machines position the graphite material lengthwise and typically move either the diamond wire or worktable laterally, enabling stable slicing of thick, heavy, or wide graphite components.

- Max Workpiece Length (mm): 600

- Max Workpiece Width (mm): 600

- Max Workpiece Height (mm): 600