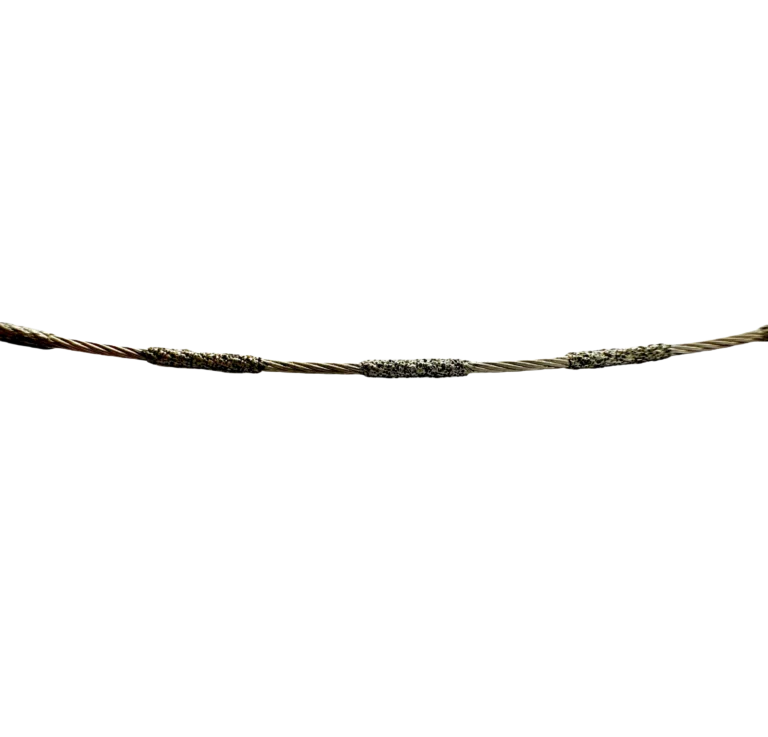

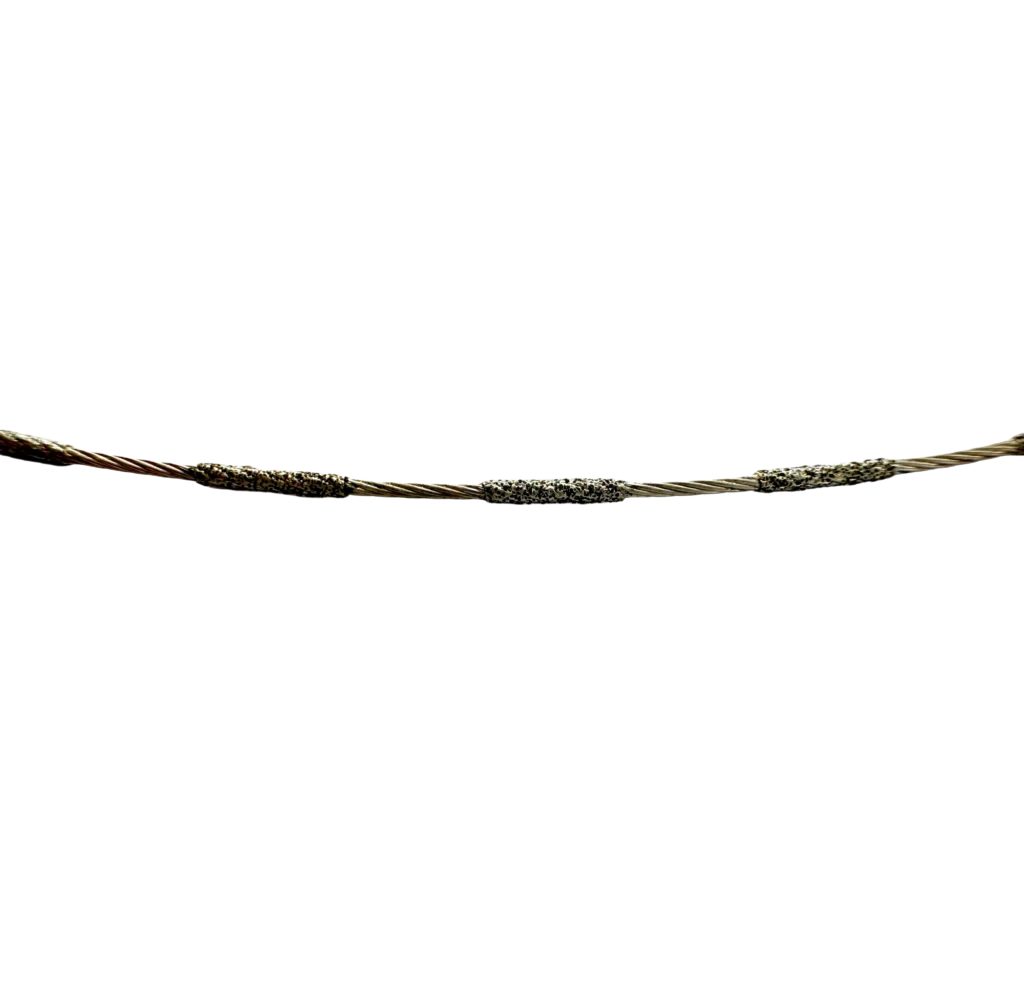

Segmented diamond wire is very useful for cutting graphite. It is strong, quick, and long-lasting. Mainly being a single, continuous line, this wire is made in segments. During cutting, this design helps in removing graphite pieces. It also reduces friction, so machines work smoothly. This wire is used in graphite-working factories to cut sheets, rods, and blocks. They save money and time as a result. Every time, segmented diamond wire makes accurate, clean cuts.

Advantages of Segmented Diamond Wire

Segmented diamond wire has many benefits. It cuts graphite easily and with less force. The segments help remove waste material while cutting. This keeps the wire and machine cooler. It also reduces friction and energy use. Clean edges result from the wire staying straight when cutting. It is more durable than typical cutting wires. It is finally less expensive to use this cable. With various cutting tasks, it is highly reliable.

Applications of Segmented Diamond Wire

This wire is used in many industries. It can cut graphite blocks, rods, and plates. Factories use it to make graphite electrodes, heat sinks, and electronic components. It works well in both small workshops and big factories. The wire is very useful when precision and speed are important. Companies in the automotive, aerospace, and electronics industries use it to make high-quality graphite products. For cutting abrasive graphite, it is one of the finest cutters.

Features of Segmented-Diamond Wire

Segmented-diamond wire has special Electroplated diamond wire. These diamonds are very hard and help cut better. The segments are not continuous, so the friction is low. Chips from cutting graphite are removed easily. The wire uses less energy and cuts smoothly. It is suitable for both regular cutters and endless diamond wire machines. Cutting is quick, clean, and effective because of its design. This wire is durable, accurate, and strong.

Segmented Diamond Wire for Graphite Cutting

Our Segmented Diamond Wire for Graphite Cutting is strong and reliable. It has electroplated diamond segments for consistent cutting. The non-continuous coating reduces wear and heat. It removes chips quickly, keeping the cutting smooth. It works with endless diamond wire systems or standard machines. The wire has low cutting resistance to save energy. It is perfect for high-volume graphite cutting jobs.

- Strong electroplated diamond segments

- Non-continuous coating reduces wear

- Fast chip removal for smooth cutting

- Works with endless diamond wire systems

- Low energy use and smooth performance

How Segmented Diamond Wire Helps Cutting

Graphite cutting is easy with segmented-diamond wire. It touches the surface evenly, which keeps the edges smooth. It keeps the wire cool by quickly removing the chips. Machines use less energy when there is less friction. This saves money and makes things work better. Every time, the wire gives the same results. It is a safe and dependable way to cut graphite.

Maintenance and Handling Tips

Be careful with the wire so it works well. Check the tension on the wire often. Keep it straight so it doesn’t break. Cutting speed and pressure should be just right. To get rid of graphite dust, clean the wire often. Following these steps will make the wire last longer. The machines are also safe, and it keeps cutting smoothly.

Why Choose Segmented-Diamond Wire

This diamond wire is strong, safe, and efficient. It cuts clean edges and lasts a long time. Chips are removed easily, so machines run continuously. Compared to standard wires, it is faster and more energy-efficient. For industries that use a lot of graphite, it is a great choice. This wire lowers costs and improves performance.

Make Graphite Cutting Easy with Segmented Diamond Wire

Do you want to cut graphite fast and clean? At Vimfun, our Diamond Wire makes cutting simple. It lasts a long time, removes waste easily, and saves energy. You always get cuts that are accurate and quick. Both big companies and small workshops may benefit from it. With this wire, you can cut more effectively and save time and money. Don’t wait—try Vimfun’s Diamond Wire today and see how easy graphite cutting can be. Buy now and make your work faster and easier! We are a top-rated manufacturer and supplier.

Graphite cutting will get easier with new wires. New wires will last longer, use less power, and cut faster. These diamond wires will stay useful in factories.

FAQs

- What is this wire used for?

It is used to cut graphite fast, clean, and easily.

- Why choose this wire for cutting?

It lasts long, cuts smoothly, and removes waste well.

- Where can this wire be used?

In factories or small workshops, graphite blocks, rods, and sheets.

- What are its main features?

Strong diamond parts, low friction, easy chip removal, and it works with many machines.

- How do I take care of this wire?

Keep it clean, check tension, and use the correct cutting speed for longer life.