Giới thiệu

Vật liệu composite sợi carbon ngày càng được sử dụng rộng rãi trong ngành hàng không vũ trụ, ô tô và quốc phòng nhờ tỷ lệ độ bền trên trọng lượng vượt trội cũng như khả năng chống mỏi và ăn mòn. Tuy nhiên, cấu trúc nhiều lớp độc đáo và các sợi có tính mài mòn khiến chúng khó cắt sạch và chính xác bằng các phương pháp thông thường. Để giải quyết những thách thức này, cắt dây kim cương Công nghệ này đã nổi lên như một giải pháp có độ chính xác cao để gia công vật liệu composite sợi carbon. Bài viết này khám phá những ưu điểm của công nghệ này và so sánh nó với các kỹ thuật cắt truyền thống.

Vì sao phương pháp cắt truyền thống gặp khó khăn với vật liệu composite sợi carbon?

Các phương pháp truyền thống như cưa cơ khí, phay CNC và cắt bằng tia nước mài mòn thường dẫn đến các vấn đề không mong muốn như tách lớp, kéo sợi, độ rộng vết cắt quá mức và hư hỏng do nhiệt. Những vấn đề này không chỉ ảnh hưởng đến chất lượng linh kiện mà còn làm tăng thời gian gia công sau đó và lãng phí vật liệu. Độ cứng và cấu trúc không đồng nhất của sợi carbon đòi hỏi một phương pháp cắt giúp giảm thiểu ứng suất cơ học đồng thời tối đa hóa độ chính xác.

Ưu điểm của công nghệ cắt dây kim cương

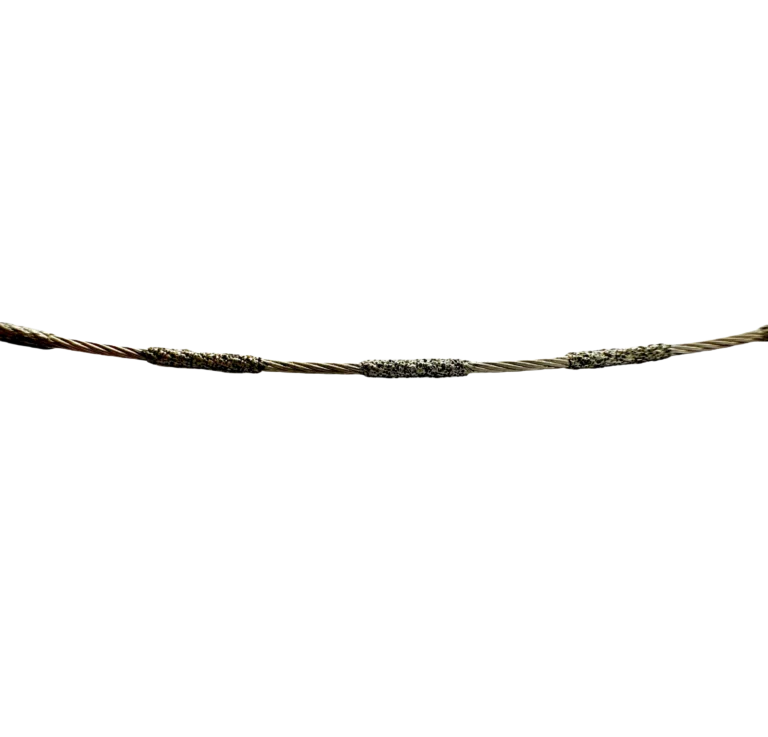

Cắt bằng dây kim cương sử dụng một vòng dây liên tục được gắn các hạt mài mòn kim cương để cắt xuyên qua vật liệu với sự tiếp xúc vật lý và nhiệt lượng tối thiểu. Dưới đây là những lợi ích chính đối với gia công vật liệu composite sợi carbon:

- Lực cắt thấp: Tính chất mài mòn của dây kim cương giúp giảm thiểu ứng suất cơ học lên vật liệu composite, giảm nguy cơ tách lớp hoặc nứt sợi.

- Độ rộng rãnh cắt hẹp: Với đường kính dây nhỏ đến 0,35 mm, độ rộng vết cắt có thể được kiểm soát ở mức khoảng 0,4 mm, giúp giảm đáng kể lượng vật liệu bị hao phí.

- Bề mặt sạch sẽ: Dây mài kim cương tạo ra các bề mặt nhẵn, đồng nhất, thường loại bỏ nhu cầu gia công hoàn thiện thứ cấp.

- Độ chính xác cao: Cho phép tạo ra các hình dạng phức tạp và các mặt cắt mỏng, điều khó có thể đạt được bằng các phương pháp truyền thống.

- Ít sinh nhiệt: Giảm nguy cơ biến dạng do nhiệt hoặc suy thoái nhựa.

So sánh hiệu suất với các phương pháp truyền thống

Để hiểu được giá trị cắt dây kim cương Vì vậy, việc so sánh nó với các kỹ thuật truyền thống sẽ rất hữu ích:

| Phương pháp cắt | Chiều rộng rãnh cắt | Hư hỏng bề mặt | Nguy cơ tách lớp | Chất thải vật liệu | Xử lý hậu kỳ |

|---|---|---|---|---|---|

| Cưa máy | ≥ 0,8 mm | Vừa phải | Cao | Cao | Thường được yêu cầu |

| Máy phun tia nước mài mòn | ~0,5 mm | Thấp | Trung bình | Trung bình | Thỉnh thoảng |

| Cắt dây kim cương | ~0,4 mm | Tối thiểu | Thấp | Thấp | Hiếm khi cần thiết |

Như đã trình bày, cắt bằng dây kim cương mang lại những ưu điểm rõ rệt về khả năng kiểm soát độ rộng vết cắt, chất lượng bề mặt và bảo toàn vật liệu.

Ứng dụng công nghiệp

Cắt bằng dây kim cương đặc biệt thích hợp cho:

- Các linh kiện hàng không vũ trụ Yêu cầu độ chính xác nhẹ.

- Phụ tùng ô tô chẳng hạn như các tấm kết cấu và các yếu tố gia cường.

- Thiết bị y tế bao gồm các phần tử composite carbon có hình dạng tùy chỉnh.

- Hàng hóa thể thao và tiêu dùng, bao gồm xe đạp và các phụ kiện làm từ sợi carbon.

Khả năng mở rộng và hiệu suất ổn định khiến nó trở thành lựa chọn đáng tin cậy cho cả môi trường nghiên cứu và phát triển cũng như sản xuất hàng loạt.

Phần kết luận

Đối với các nhà sản xuất sử dụng vật liệu composite sợi carbon, cắt bằng dây kim cương mang đến một phương pháp đột phá giúp đạt được kết quả sạch hơn, chính xác hơn và hiệu quả hơn. Không giống như các phương pháp truyền thống thường làm ảnh hưởng đến độ bền vật liệu và tăng chi phí sản xuất, cắt bằng dây kim cương cho phép các nhà sản xuất đáp ứng các tiêu chuẩn hiệu suất cao với lượng chất thải tối thiểu.