Nói thật lòng, cắt những vật liệu siêu cứng có thể rất khó khăn. Bạn cần một dụng cụ mạnh mẽ, nhanh chóng và cho ra thành phẩm gọn gàng. Đó là lý do tại sao vòng dây kim cương phủ xoắn ốc Được ưa chuộng rộng rãi trong nhiều ngành nghề. Nó cực kỳ bền chắc và cho ra những đường cắt đáng tin cậy. Thêm vào đó, nó rất tuyệt vời cho các vật liệu như thủy tinh, silicon, sapphire và thạch anh.

Ngày nay, các cửa hàng cần những thứ giúp tiết kiệm thời gian, giảm thiểu lãng phí và duy trì chất lượng hàng hóa ở mức cao nhất. máy cắt vòng dây kim cương xoắn ốc Nó thực sự là một người bạn đồng hành tuyệt vời. Nó cắt rất sạch, bền bỉ và hoạt động tốt, ngay cả khi bạn sử dụng nhiều.

Điều gì khiến dây kim cương phủ xoắn ốc có độ bền cao đến vậy?

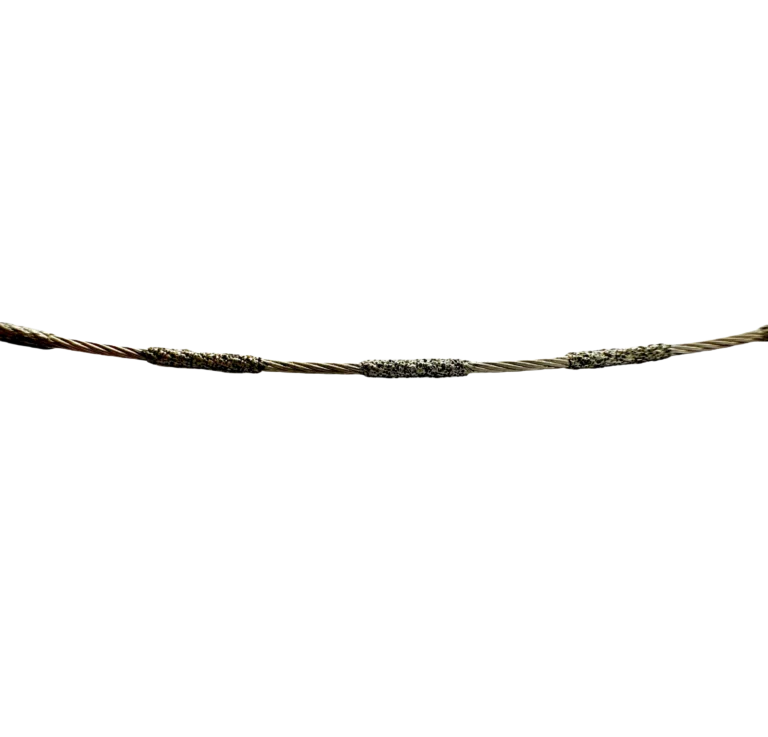

Tất cả nằm ở cách nó được chế tạo. Sợi dây này có những mảnh kim cương nhỏ li ti gắn vào theo hình xoắn ốc. Và những viên kim cương đó cực kỳ cứng. Kim cương là một trong những vật liệu cứng nhất! Vì vậy, điều đó mang lại cho sợi dây khả năng cắt rất mạnh.

Cái lưỡi xoắn ốc đó cũng khá thông minh. Nó phân tán lực khi cắt dọc theo toàn bộ sợi dây, vì vậy nó giữ được độ ổn định và không dễ bị gãy. Bạn sẽ sử dụng được lâu hơn và có những đường cắt sạch hơn. Lớp phủ đó bảo vệ dây khỏi bị hư hại, nhiệt và ma sát. Và điều đó cũng có nghĩa là nó vẫn sắc bén, ngay cả sau khi bạn đã cắt trong nhiều giờ.

Vòng dây kim cương phủ xoắn ốc hiệu suất cao

Dây này, giống như vòng dây kim cương hiệu suất cao Với phương pháp cắt than chì, sản phẩm này mang lại những đường cắt nhanh, mịn và sạch.

Thiết kế xoắn ốc đó giúp các mảnh kim cương được bố trí sao cho không khí lưu thông tốt hơn và bụi bẩn không bị cản trở. Điều này giúp ngăn ngừa dây mài bị tắc nghẽn, đảm bảo quá trình cắt diễn ra trơn tru.

Nó cũng loại bỏ phoi vụn nhanh chóng, điều này cực kỳ hữu ích khi bạn cắt mà không có nhiều chất lỏng. Bạn sẽ có tốc độ cắt tốt hơn và lượng bụi tích tụ cũng ít hơn. Các mũi kim cương sắc bén luôn sẵn sàng để cắt, vì vậy dây có thể cắt xuyên qua than chì cứng mà không gặp vấn đề gì.

Một điểm hay nữa là nó là một vòng lớn liền mạch, vì vậy nó hoạt động với tất cả các loại cưa dây kim cương dạng vòng, bao gồm cả máy của Vimfun và nhiều hãng khác. Vòng dây chắc chắn này rất phù hợp cho những công việc nhanh chóng, cần sự sạch sẽ và chính xác.

Được thiết kế cho các ứng dụng cắt gọt khắc nghiệt

Đôi khi, bạn cần cắt những thứ rất cứng, dễ vỡ hoặc dễ bị nóng. Dây cắt thông thường khó có thể làm được điều đó. Chúng dễ bị gãy hoặc không cắt đều. Nhưng dây cắt vòng xoắn phủ kim cương được thiết kế để xử lý những trường hợp khó khăn đó.

Nó hoạt động tốt ngay cả khi bạn dùng lực mạnh. Nó có thể cắt xuyên qua các khối silicon, thanh sapphire, tấm thạch anh và khối than chì. Hơn nữa, nó giữ nguyên vị trí khi cắt. Điều này rất quan trọng vì bạn cần phải cẩn thận khi cắt những vật liệu cứng. Dây không bị rung lắc hay trượt, vì vậy bạn sẽ có được đường cắt tốt mỗi lần.

Cắt chính xác cao với lượng vật liệu lãng phí tối thiểu

Ngày nay ai cũng muốn sự chính xác. Ngay cả một sai sót nhỏ cũng có thể gây ra hậu quả nghiêm trọng. Vòng dây kim cương phủ xoắn ốc Giúp giảm thiểu những sai sót. Nó cắt rất chính xác và không cắt bỏ quá nhiều phần thừa khi cắt.

Bởi vì vòng dây kim cương phủ xoắn ốc Nó khá mỏng, cắt rất sát mép, nên bạn không bị mất nhiều vật liệu dưới dạng bụi. Điều này rất tuyệt nếu bạn đang làm việc với những vật liệu đắt tiền như silicon hoặc sapphire. Khi dây cắt sạch và thẳng, các xưởng sẽ tiết kiệm được vật liệu và tiền bạc. Thêm vào đó, bạn không cần phải làm nhiều công việc sau khi cắt.

Khả năng chống mài mòn vượt trội cho thời gian sử dụng lâu dài.

Cắt những vật liệu siêu cứng sẽ tạo ra ma sát, điều này có thể làm hỏng các loại dây thông thường. Nhưng dây kim cương dạng vòng xoắn ốc lại có khả năng chống ma sát rất tốt. Điều đó có nghĩa là nó có thể xử lý các bề mặt gồ ghề mà không bị mòn quá sớm.

Lớp phủ xoắn ốc đó giúp bảo vệ dây khỏi nhiệt và lực tác động. Các viên kim cương vẫn giữ nguyên vị trí, ngay cả sau khi bạn đã sử dụng chúng nhiều lần. Nhờ vậy, dây có độ bền cao và bạn không cần phải thay thế thường xuyên. Điều này giúp bạn tiết kiệm chi phí và cắt nhanh hơn.

Hiệu suất ổn định trên cả vật liệu cứng và giòn.

Một trong những điều tuyệt vời nhất về điều này vòng dây kim cương phủ xoắn ốc Ưu điểm của nó là hoạt động tốt bất kể bạn đang cố gắng cắt vật liệu gì. Các vật liệu cứng, dễ vỡ thường bị nứt hoặc vỡ vụn, nhưng dây này cắt trơn tru và ngăn chặn điều đó xảy ra.

Hình dạng xoắn ốc giúp các viên kim cương cắt đều, và lớp phủ giữ cho dây thẳng. Điều đó có nghĩa là bạn sẽ có được kết quả tốt như nhau bất kể bạn đang làm việc với vật liệu gì. Cho dù bạn đang cắt vật liệu dày hay mỏng, dây vẫn đáng tin cậy.

Thích hợp cho thủy tinh, silicon, sapphire, thạch anh và nhiều chất liệu khác.

Dây kim cương xoắn ốc được sử dụng trong rất nhiều công việc vì chúng có thể làm được rất nhiều việc. Nó rất tuyệt vời để cắt lát:

- Tấm kính

- Silicon

- ngọc bích

- Thạch anh

- Gốm cứng

- Than chì

- Các bộ phận quang học

Mỗi loại vật liệu này đều nổi tiếng là cứng hoặc dễ vỡ. Các dụng cụ thông thường có thể làm nứt hoặc để lại các cạnh sắc nhọn, nhưng vòng dây kim cương phủ xoắn ốc Mang lại kết quả mượt mà, sạch sẽ. Nó cũng giúp nâng cao chất lượng sản phẩm, điều rất quan trọng trong các ngành như điện tử, quang học, năng lượng mặt trời và các vật liệu đòi hỏi kỹ thuật cao.

Giải thích về công nghệ phủ xoắn ốc tiên tiến

Bí quyết tạo nên độ bền của sợi dây nằm ở lớp phủ xoắn ốc. Lớp phủ này được thiết kế để giữ các mảnh kim cương theo hình xoắn ốc. Hình dạng đó giúp tạo ra nhiều điểm cắt hơn trên sợi dây.

Càng nhiều điểm tiếp xúc thì đường cắt càng mượt mà hơn. Thiết kế xoắn ốc cũng tạo thêm không gian để làm mát và loại bỏ vụn vật liệu. Khi cắt vật liệu cứng, vụn vật liệu có thể gây cản trở và làm xước, nhưng thiết kế xoắn ốc giúp loại bỏ chúng nhanh hơn.

Tại sao nên chọn dây kim cương của chúng tôi?

Chúng tôi tạo ra sản phẩm của mình. vòng dây kim cương vô tận cho than chì Mang đến cho bạn những đường cắt sắc nét, bền lâu và kết quả hoàn hảo. vòng dây kim cương phủ xoắn ốc Dây dẫn được kiểm tra kỹ lưỡng để đảm bảo độ bền và độ tin cậy. Chúng tôi cũng rất quan tâm đến sự an toàn, vì vậy dây dẫn hoạt động tốt ngay cả trong các máy cắt tốc độ cao.

Ngoài ra, Vimfun còn sản xuất máy cắt dây kim cương dùng cho than chì và các vật liệu khó cắt. Họ thực sự chú trọng đến công nghệ, độ chính xác và cách sử dụng máy móc. Khi bạn sử dụng sản phẩm của chúng tôi, cưa vòng xoắn ốc kim cương chính xác Với các máy học từ Vimfun, bạn sẽ có được kết quả thậm chí còn tốt hơn.

Có thể đặt làm dây dẫn với kích thước và thông số kỹ thuật theo yêu cầu.

Các công việc khác nhau đòi hỏi kích thước dây khác nhau. Một số vết cắt cần dây rất mỏng, trong khi những vết khác lại cần dây dày hơn, chắc chắn hơn. Đó là lý do tại sao chúng tôi cung cấp các kích thước tùy chỉnh. Bạn có thể chọn kích thước dây, chiều dài và loại lớp phủ dựa trên nhu cầu của mình.

Chúng tôi cũng giúp bạn chọn lựa tốt nhất. cắt kim cương mạ điện xoắn ốc Chúng tôi cung cấp dây cắt phù hợp với vật liệu và mục tiêu cắt của bạn. Nếu bạn cần những đường cắt siêu chính xác, chúng tôi có thể đề xuất các loại dây mỏng hơn. Nếu bạn đang sử dụng các vật liệu thực sự cứng, chúng tôi có thể cung cấp cho bạn các loại dây chắc chắn hơn với lớp phủ dày hơn. Chúng tôi muốn giúp bạn đạt được kết quả tốt nhất mọi lúc.

Nguồn cung ổn định, giao hàng nhanh chóng và hỗ trợ chuyên nghiệp.

Thời gian là tiền bạc. Bạn không thể chờ đợi mãi để có hàng. Đó là lý do tại sao chúng tôi cung cấp dịch vụ giao hàng đáng tin cậy và dây kim cương luôn có sẵn. Chúng tôi luôn dự trữ đầy đủ hàng, vì vậy bạn có thể nhận được dây khi cần.

Chúng tôi cũng có đội ngũ nhân viên sẵn sàng hỗ trợ. Nếu bạn có thắc mắc về dây, cắt hoặc cài đặt máy, nhóm của chúng tôi có thể hướng dẫn bạn đúng cách. Họ có thể giúp bạn chọn loại dây phù hợp, thiết lập tốc độ phù hợp và đạt được kết quả tốt nhất. Chúng tôi muốn đảm bảo mọi việc diễn ra suôn sẻ cho bạn.

Tóm lại là...

Dây cắt kim cương phủ xoắn ốc là lựa chọn tuyệt vời để cắt những vật liệu cứng. Nó chắc chắn, bền lâu và cắt rất cẩn thận. Lớp phủ xoắn ốc giúp nó cắt dễ dàng và giữ được độ sắc bén. Nhiều ngành công nghiệp tin dùng nó để cắt các vật liệu như thủy tinh, silicon, sapphire, thạch anh, than chì, và nhiều hơn nữa. Lớp phủ xoắn ốc cao cấp và khả năng chống mài mòn mang đến cho bạn những đường cắt đáng tin cậy. Và khi bạn sử dụng nó với các máy móc từ... Vimfun, Mọi thứ sẽ ngày càng tốt hơn.

Nếu bạn muốn duy trì sự nhất quán, hãy sử dụng dụng cụ bền và cắt tỉa gọn gàng. Vòng dây kim cương dùng để cắt khô Đó là cách tốt nhất.

Câu trả lời nhanh

Dây kim cương phủ xoắn ốc là gì? Đó là loại dây chắc chắn với các hạt kim cương được sắp xếp theo hình xoắn ốc để cắt.

Tại sao? Lớp phủ giúp bảo vệ các viên kim cương, nhờ đó dây dẫn sẽ bền lâu.

Cắt được những gì? Thủy tinh, silicon, sapphire, thạch anh, than chì và các vật liệu cứng khác.

Giảm thiểu lãng phí? Đúng vậy! Đó là một sợi dây mỏng cắt được đường thẳng hẹp.

Kích thước tùy chỉnh? Chắc chắn rồi! Hãy chọn những gì bạn cần.