Máy cắt biên dạng bên trong bằng than chì của chúng tôi được thiết kế và sản xuất cẩn thận với độ chính xác cao. Bạn có thể sử dụng chúng trong các ngành công nghiệp chế tạo khuôn mẫu và gia công kim loại. Những máy móc này là lựa chọn tốt nhất để có được những đường cắt chất lượng, mượt mà và an toàn nhất mỗi lần sử dụng. Hãy sử dụng các thiết bị này để đảm bảo quy trình đúc khuôn và gia công của bạn luôn diễn ra suôn sẻ. Bạn có thể sử dụng các thiết bị này trong nhiều lĩnh vực khác nhau để đạt được kết quả chính xác.

Bảng điều khiển thông minh của máy cho phép bạn thiết lập tất cả các quy trình cắt và tùy chỉnh hình dạng cho các sản phẩm cắt. Máy được chế tạo với các bộ phận thân máy có khả năng chịu được thời tiết khắc nghiệt. Thiết kế chống gỉ của máy giúp bạn tạo ra những sản phẩm cắt chất lượng chính xác trong nhiều năm.

Ứng dụng của máy gia công biên dạng bên trong bằng than chì

Máy CNC gia công biên dạng bên trong bằng than chì giúp người dùng chế tạo khuôn mẫu một cách sạch sẽ, trơn tru và dễ dàng. Nó tạo hình than chì thành các chi tiết mềm mại, gọn gàng và tinh xảo với các góc sắc nét và các cạnh đều đặn. Mỗi đường cắt đều mịn, bóng và đồng nhất mỗi lần. Máy được thiết kế để tạo ra các đường cắt biên dạng than chì có độ chính xác cao, trông gọn gàng và hoàn toàn phù hợp cho việc chế tạo khuôn mẫu và dụng cụ. Nó cũng tạo ra rất ít bụi và chất thải, giữ cho nơi làm việc của bạn sạch sẽ và an toàn. Điều này giúp công việc nhanh hơn, dễ dàng hơn và thoải mái hơn cho mọi người sử dụng.

Cắt than chì dễ dàng và mượt mà

Khi cắt than chì, mục tiêu là duy trì bề mặt phẳng và nhẵn, không bị nứt hoặc vỡ vụn. Máy định hình bên trong bằng than chì Giúp việc này trở nên dễ dàng hơn. Nó di chuyển chậm và nhẹ nhàng, cho phép kiểm soát hoàn toàn và tạo ra những đường cắt hoàn hảo. Điều này cho phép bạn tạo ra các dụng cụ bằng than chì có đường cắt định hình bên trong vừa khít với khuôn của bạn. Hệ thống làm mát giữ cho than chì không bị nóng lên, vì vậy bạn có thể cắt định hình than chì mà không bị vỡ vụn hoặc cháy. Mỗi đường cắt đều trông đều và gọn gàng, lý tưởng cho cả những người làm khuôn nhỏ và lớn, những người yêu cầu hình dạng sạch sẽ và chính xác mỗi khi làm việc.

Máy móc mạnh mẽ và đáng tin cậy từ VIMFUN

VIMFUN thiết kế các loại máy móc mạnh mẽ, ổn định và dễ sử dụng. Mỗi mẫu máy đều được chế tạo để sử dụng lâu dài mà vẫn đảm bảo độ chính xác. Những chiếc máy này có thể dễ dàng thực hiện cả các đường cắt bên trong và bên ngoài. Ngay cả sau nhiều giờ làm việc, chúng vẫn hoạt động trơn tru và chắc chắn mà không làm giảm độ chính xác. Dưới đây là một số mẫu máy tốt nhất do VIMFUN sản xuất, hoạt động hiệu quả trong nhiều xưởng khác nhau, từ các xưởng nhỏ đến các nhà máy lớn.

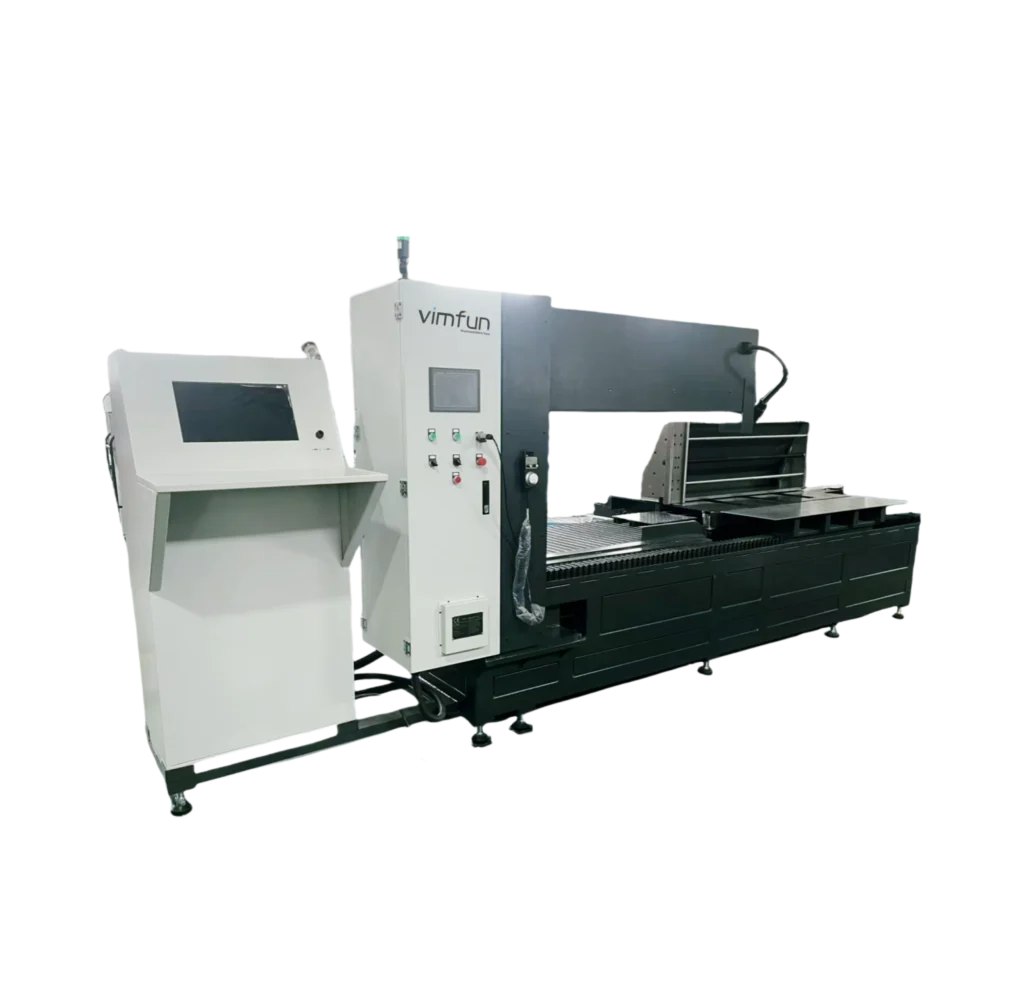

- Máy cắt than chì tự động CNC SVI 160-100

Các Máy cắt than chì tự động CNC SVI 160-100 Máy này được chế tạo để cắt các khối than chì lớn với công suất và tốc độ cao. Nó có khung chắc chắn giúp máy ổn định trong quá trình sử dụng. Máy giúp bạn tạo ra các đường cắt than chì theo yêu cầu một cách nhanh chóng và dễ dàng. Hệ thống tự động tiên tiến cho phép bạn thực hiện các công việc dài với ít sự hỗ trợ hơn, tiết kiệm thời gian và năng lượng. Mỗi đường cắt đều mịn, sạch và chính xác. Điều này làm cho nó trở thành lựa chọn tốt nhất cho các nhà sản xuất khuôn mẫu và khuôn dập đang tìm kiếm những chiếc máy chất lượng cao, bền bỉ.

- Máy cắt biên dạng ngoài bằng than chì SVI 60-60

Các Máy cắt biên dạng ngoài bằng than chì SVI 60-60 Máy này được thiết kế để tạo hình các mặt ngoài của khuôn. Nó tạo ra các cạnh mềm mại, đều và chi tiết với các đường nét mượt mà. Bạn cũng có thể sử dụng nó với các lưỡi bào than chì định hình bên trong cho các dụng cụ tạo hình để tạo ra các hình dạng khuôn hoàn chỉnh hơn. Máy hoạt động êm ái, dễ sử dụng và hoàn hảo cho cả các xưởng lớn và nhỏ. Nó tạo ra các đường cắt gọn gàng và đều với tiếng ồn, độ rung và độ lắc tối thiểu. Model này là một lựa chọn thông minh cho các xưởng yêu cầu tốc độ cao, tiếng ồn thấp và kết quả sạch sẽ.

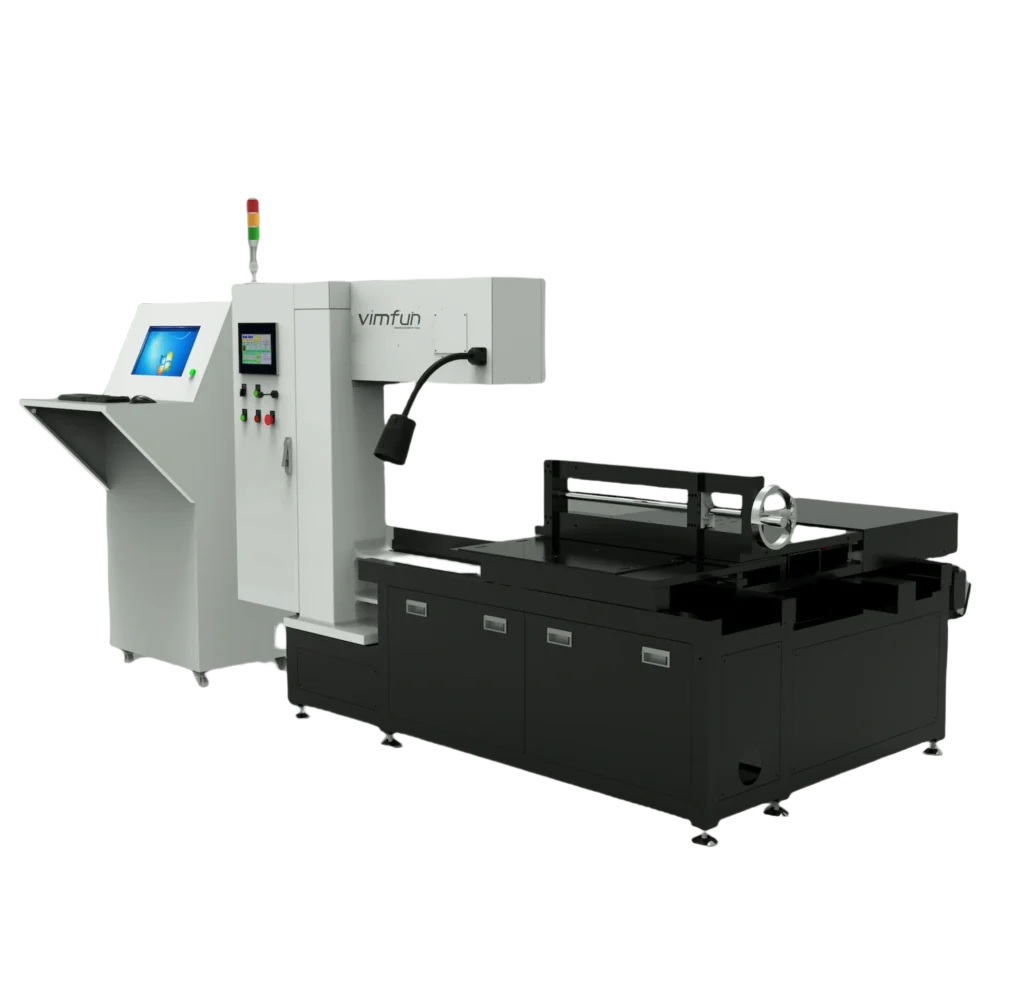

- Máy cắt biên dạng trong bằng than chì SVI 80-80

Máy cắt biên dạng trong bằng than chì SVI 80-80 nhỏ gọn nhưng mạnh mẽ. Máy được thiết kế cho các công việc tinh tế và chi tiết, đòi hỏi sự điều khiển chính xác. Đây là sự lựa chọn phù hợp cho các xưởng dịch vụ cắt biên dạng trong bằng than chì. Hệ thống điều khiển cho phép bạn dễ dàng thiết lập tốc độ, độ sâu và tốc độ cấp liệu. Máy cũng có bộ hút bụi tích hợp để giữ cho khu vực làm việc sạch sẽ. Ngay cả với các chi tiết nhỏ, máy này cũng cho ra các đường cắt sáng bóng và đều, trông hoàn hảo mọi lúc.

Giữ máy ở vị trí tốt hơn

Chăm sóc tốt sẽ giúp bạn Máy định hình bên trong bằng than chì Khỏe mạnh và hoạt động tốt trong thời gian dài. Hãy thử thực hiện những bước đơn giản này mỗi ngày:

- Sau mỗi lần hoàn thành công việc, hãy lau sạch bụi và các mảnh vụn nhỏ.

- Bôi trơn các bộ phận chuyển động để tránh bị kẹt.

- Kiểm tra các bu lông và ốc vít, siết chặt chúng khi cần thiết.

- Thực hiện các thao tác cắt thử nhỏ sau khi thay lưỡi dao.

- Hãy lập danh sách kiểm tra định kỳ để theo dõi quá trình chăm sóc và kiểm tra.

Với việc bảo dưỡng đúng cách máy cắt biên dạng than chì, bạn sẽ đạt được kết quả tốt hơn, ít hỏng hóc hơn và thời gian sử dụng hàng ngày lâu hơn.

Giá cả và giá trị của máy cắt biên dạng than chì

Khi bạn nhìn vào Máy định hình bên trong bằng than chì Hãy cân nhắc giữa giá cả, chất lượng, tuổi thọ và giá trị sử dụng. Máy móc VIMFUN mang lại hiệu suất tuyệt vời và tiết kiệm điện năng. Chúng hoạt động trơn tru trong nhiều năm với những sửa chữa nhỏ cần thiết. Mua một chiếc máy mang lại cho bạn giá trị tốt, sự an toàn và sức mạnh. Mỗi mẫu máy được thiết kế dành cho những người chế tạo khuôn mẫu và dụng cụ muốn có kết quả chất lượng cao mà không phải chịu chi phí quá lớn. Đó là sự lựa chọn thông minh cho bất cứ ai muốn kết hợp hiệu suất với tiết kiệm chi phí.

Mẹo bổ sung để cắt tốt hơn

Dưới đây là một số mẹo cần thiết để cắt vật liệu một cách gọn gàng:

- Luôn sử dụng lưỡi dao sạch và sắc bén.

- Hãy đeo khẩu trang và kính để tránh bụi.

- Hãy thử tốc độ trên những mảnh nhỏ trước.

- Sử dụng đế phẳng, chắc chắn để tránh bị rung lắc.

- Chọn loại than chì phù hợp để có bề mặt hoàn thiện mịn hơn.

- Hãy lưu lại các thiết lập tốt nhất cho lần sau.

Những bước đơn giản này giúp bạn có được những đường cắt mượt mà hơn, kéo dài tuổi thọ dụng cụ và đạt được kết quả tốt hơn mỗi khi làm việc.

Nơi lý tưởng để mua máy gia công biên dạng bên trong bằng than chì.

VIMFUN Đây là nơi tốt nhất để mua máy gia công biên dạng bên trong bằng than chì, vì họ cung cấp hỗ trợ đầy đủ trước và sau khi mua để đảm bảo bạn sử dụng máy một cách hiệu quả nhất. Trang web cũng cung cấp hỗ trợ đầy đủ, các mẹo và hướng dẫn sử dụng máy. Bạn có thể mua các thiết bị chất lượng tốt nhất từ họ với giá cả hợp lý. Họ cung cấp cho bạn dịch vụ tốt nhất và các sản phẩm chất lượng chính xác theo dự án của bạn.

Câu hỏi thường gặp

- Máy gia công biên dạng bên trong bằng than chì có chức năng gì?

Nó cắt than chì thành những hình dạng gọn gàng để làm khuôn, khuôn dập và các công cụ được sử dụng trong nhiều ngành công nghiệp.

- Làm thế nào để cắt than chì mà không tạo ra vụn?

Hãy sử dụng dụng cụ sắc bén, thao tác chậm rãi và giữ cho phôi luôn mát khi cắt rãnh than chì mà không tạo ra mảnh vụn.

- Tôi cần chăm sóc máy móc của mình như thế nào?

Hãy vệ sinh, tra dầu và kiểm tra tất cả các bộ phận sau mỗi lần sử dụng để đảm bảo máy hoạt động trơn tru.

- Một máy có thể cắt cả hình dạng bên trong và bên ngoài không?

Đúng vậy. VIMFUN sản xuất các loại máy có thể thực hiện cả hai loại cắt một cách dễ dàng.

- Làm sao để chọn được cái tốt nhất?

Hãy cân nhắc quy mô công việc, loại công việc và giá cả của máy cắt biên dạng than chì.

- Tôi có thể mua nó ở đâu?

Bạn có thể truy cập trang web của VIMFUN để xem tất cả các mẫu, video và tùy chọn mua hàng.