Máy cắt định hình ngoài bằng than chì được sử dụng để cắt than chì với độ chính xác cao. Than chì vừa cứng vừa giòn. Nếu cắt không đúng cách, nó rất dễ vỡ. Vì lý do này, cần có máy móc chuyên dụng. Máy cắt than chì hiện đại cho ra những đường cắt mịn và các cạnh sắc nét. Nó hoạt động với hệ thống điều khiển CNC để dẫn hướng đường cắt. Điều này giúp giảm thiểu sai sót trong quá trình làm việc. Nhiều nhà máy sử dụng máy này để cắt an toàn và ổn định. Nó lý tưởng cho các ngành công nghiệp cần những hình dạng than chì hoàn hảo mọi lúc.

Tầm quan trọng của việc cắt than chì bằng máy CNC chính xác

Cắt chính xác than chì là điều thiết yếu trong sản xuất hiện đại. Các bộ phận làm từ than chì phải có kích thước chính xác như nhau. Ngay cả những sai sót nhỏ cũng có thể dẫn đến những vấn đề lớn. Cắt biên dạng CNC cho phép kiểm soát chính xác mọi chuyển động của máy. Điều này đảm bảo quá trình cắt diễn ra trơn tru và ổn định. Máy cưa dây chuyên dụng cho than chì phân bổ áp lực đều, giúp ngăn ngừa nứt và vỡ vụn. Cắt chính xác cũng giúp cải thiện tuổi thọ sản phẩm, cho phép các nhà máy sản xuất cùng một bộ phận nhiều lần với chất lượng nhất quán.

Công nghệ đằng sau kỹ thuật cắt dây kim cương

Công nghệ máy cắt dây kim cương Được sử dụng rộng rãi để cắt than chì. Nó sử dụng một sợi dây mỏng được phủ kim cương. Lưỡi cưa dây kim cương chuyển động theo vòng lặp. Điều này tạo ra vết cắt mịn và đều. Nó giảm nhiệt và ma sát trong quá trình làm việc. Điều này đặc biệt hữu ích cho việc cắt khối than chì. So với cắt bằng lưỡi dao, cắt bằng dây kim cương gây ra ít hư hại hơn. Nó cũng tạo ra ít chất thải hơn. Phương pháp này cải thiện độ chính xác khi cắt và độ hoàn thiện bề mặt. Nó được tin dùng cho các công việc CNC chất lượng cao.

Cắt biên dạng CNC cho các hình dạng phức tạp

Cắt định hình bằng máy CNC cho phép máy móc dễ dàng cắt nhiều hình dạng khác nhau. Các chi tiết bằng than chì thường có các cạnh và đường cong nhạy cảm. Việc cắt các hình dạng này bằng tay rất khó khăn. Hệ thống CNC tuân theo các thiết kế kỹ thuật số với độ chính xác cao. Điều này làm cho việc cắt các hình dạng phức tạp trở nên đáng tin cậy và đơn giản. Máy lặp lại cùng một thiết kế một cách hoàn hảo mỗi lần. Điều này rất hữu ích cho việc sản xuất khuôn mẫu và điện cực. Cắt CNC cũng tiết kiệm thời gian. Nó giảm thiểu sức lao động của con người và cải thiện an toàn.

Khả năng cắt than chì khổ lớn

Việc cắt than chì khổ lớn là cần thiết cho các bộ phận công nghiệp quan trọng. Các bộ phận này được sử dụng trong lò nung và thiết bị hạng nặng. Máy cắt biên dạng ngoài bằng than chì được chế tạo cho kích thước lớn có thân máy chắc chắn. Nó giữ cho dây ổn định trong quá trình cắt. Điều này làm giảm rung động và tiếng ồn. Các khối than chì lớn có thể được cắt trong một lần thiết lập. Điều này tiết kiệm thời gian và nhân công. Máy vẫn duy trì độ chính xác như cũ ngay cả với vật liệu lớn. Điều này cho phép các nhà máy hoạt động hiệu quả và năng suất hơn.

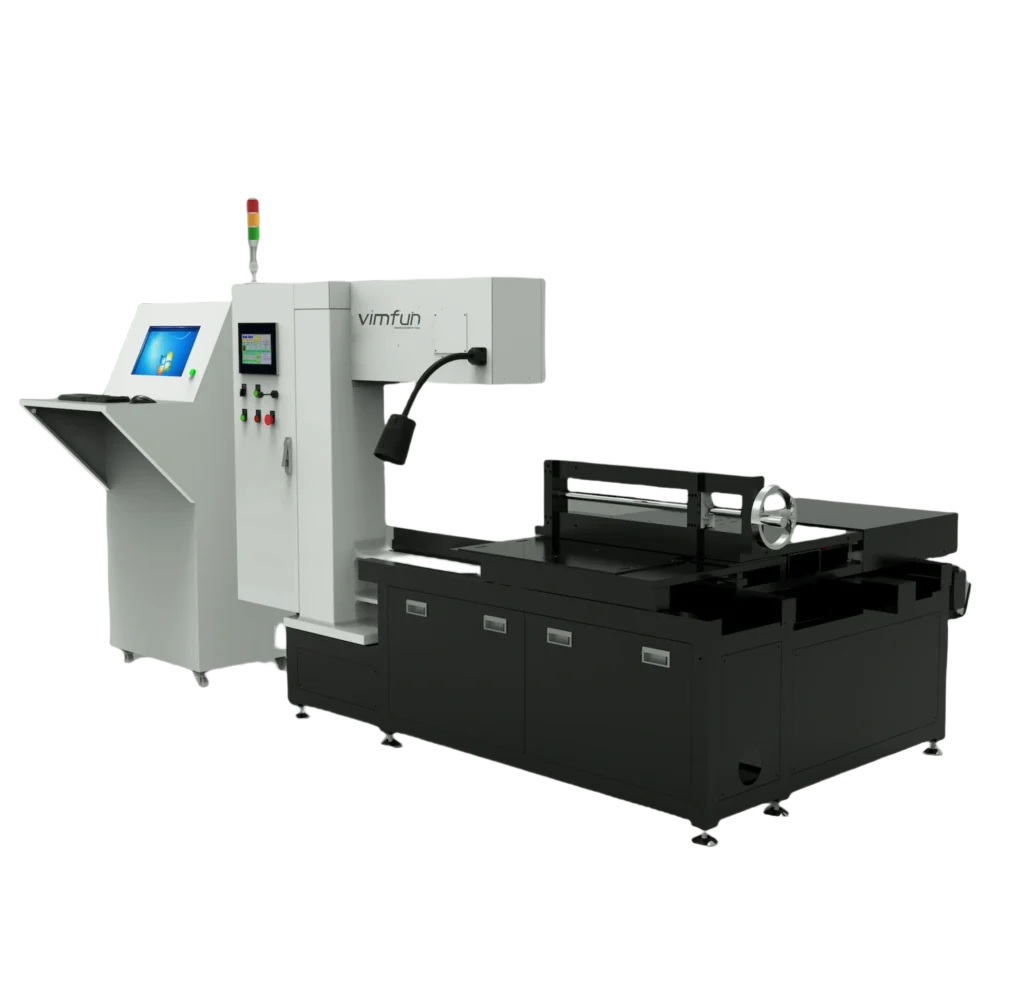

Máy cắt biên dạng ngoài bằng than chì SVI 60-60

Các Máy cắt biên dạng ngoài bằng than chì SVI 60-60 Máy này được chế tạo để gia công CNC chính xác. Nó hỗ trợ các chức năng cắt biên dạng CNC tiên tiến. Máy hoạt động ổn định và dễ vận hành. Nó hoạt động tốt cho việc cắt than chì chính xác và cắt than chì khổ lớn. Nó cũng phù hợp cho việc cắt các hình dạng phức tạp. Thiết kế cho phép làm việc nhiều giờ mà không ảnh hưởng đến độ chính xác. Điều này làm cho nó trở thành một lựa chọn tốt cho người dùng công nghiệp.

- Sử dụng công nghệ cưa dây kim cương vô tận.

- Hoạt động như một máy cưa dây dùng cho vật liệu than chì.

- Hỗ trợ các tác vụ cắt khối than chì

- Được thiết kế để cắt biên dạng ngoài ổn định.

Ứng dụng trong các ngành công nghiệp

A Máy cắt biên dạng ngoài bằng than chì Nó được sử dụng trong nhiều ngành công nghiệp. Nó được dùng để làm điện cực than chì trong sản xuất điện tử. Nó được sử dụng trong các nhà máy năng lượng để chế tạo các bộ phận than chì chịu nhiệt. Các nhà máy sản xuất khuôn mẫu phụ thuộc vào việc cắt than chì chính xác để tạo ra các chi tiết nhỏ. Các công ty hàng không vũ trụ sử dụng nó để tạo ra các bộ phận chắc chắn và nhẹ. Hệ thống máy cắt dây kim cương đáp ứng nhiều nhu cầu khác nhau. Nó giúp các công ty đáp ứng các quy định chất lượng nghiêm ngặt. Điều này làm cho máy móc trở nên có giá trị trong nhiều lĩnh vực sản xuất khác nhau.

Lợi ích về hiệu quả và chi phí

Sử dụng máy cắt than chì hiện đại giúp cải thiện tốc độ làm việc. Cắt bằng dây kim cương giảm thiểu lãng phí vật liệu. Ngoài ra, nó còn ngăn ngừa hư hỏng dụng cụ. Sai sót do thao tác thủ công được giảm thiểu nhờ cắt biên dạng CNC. Điều này giúp tiết kiệm chi phí sửa chữa và làm lại. Một máy có thể thực hiện nhiều nhiệm vụ cắt khác nhau. Điều này giúp cải thiện năng suất nhà máy. Theo thời gian, Máy cắt biên dạng ngoài bằng than chì Giúp giảm tổng chi phí sản xuất. Đồng thời, cải thiện chất lượng sản phẩm cuối cùng và sự hài lòng của khách hàng.

Tổng quan kỹ thuật

| Tính năng | Sự miêu tả |

| Phương pháp cắt | Máy cắt dây kim cương |

| Loại dây | Cưa dây kim cương vô tận |

| Hệ thống điều khiển | Cắt định hình CNC |

| Vật liệu | Cắt khối than chì |

| Sự chính xác | Cắt than chì chính xác |

| Cắt hình dạng | Cắt hình dạng phức tạp |

| Phạm vi kích thước | Cắt than chì khổ lớn |

| Ứng dụng | Cưa dây để cắt các hình dạng bằng than chì. |

Nâng cấp khả năng cắt than chì của bạn với máy CNC dễ sử dụng và chính xác.

Nâng tầm kỹ năng cắt than chì của bạn lên một đẳng cấp mới với Vimfun. Máy cắt định hình ngoài bằng than chì của chúng tôi rất dễ sử dụng, cho ra những đường cắt sạch và chính xác. Nó giúp bạn cắt than chì một cách trơn tru và an toàn mỗi ngày. Bạn có thể tạo ra cả những hình dạng đơn giản và phức tạp một cách thành công. Máy bền bỉ và hoạt động ổn định trong thời gian dài. Máy Vimfun giúp tiết kiệm thời gian và giảm thiểu lãng phí. Truy cập trang web của Vimfun để xem chi tiết sản phẩm chính xác và các tính năng thực tế của máy. Liên hệ với Vimfun ngay hôm nay để nhận được sự hỗ trợ thân thiện và tìm được máy lý tưởng cho nhu cầu cắt than chì của bạn.

A Máy cắt biên dạng ngoài bằng than chì Máy cắt than chì với độ chính xác cao. Nó sử dụng công nghệ CNC và dây kim cương để tiết kiệm vật liệu và đảm bảo điều kiện làm việc an toàn. Máy này dễ sử dụng và hoạt động hiệu quả cho việc cắt nhanh.

Câu hỏi thường gặp

- Máy cắt định hình ngoài bằng than chì là gì?

Máy cắt định hình ngoài bằng than chì là một công cụ dùng để cắt than chì thành các hình dạng sạch và chính xác.

- Tại sao máy CNC được sử dụng trong gia công cắt than chì?

Công nghệ CNC giúp máy cắt than chì chính xác và luôn đi đúng đường dẫn.

- Máy cắt dây kim cương là gì?

Đây là một loại máy sử dụng dây có gắn kim cương để cắt than chì một cách trơn tru và an toàn.

- Nó có thể cắt được các khối than chì lớn không?

Đúng vậy, nó có thể cắt các khối than chì lớn mà không làm vỡ hoặc lãng phí vật liệu.

- Nó có thể cắt được những hình dạng nào?

Nó có thể cắt các hình dạng đơn giản và phức tạp với độ chính xác cao.

- Tại sao nó lại tốt hơn các dụng cụ cắt thông thường?

Phương pháp này nhanh hơn, an toàn hơn, giảm thiểu lãng phí mà vẫn cho ra những vết cắt gọn gàng.