Máy cắt than chì này được chế tạo cho các công việc phức tạp đòi hỏi những đường cắt chắc chắn và ổn định. Máy cắt trơn tru, nhanh chóng và tạo ra những đường thẳng không bị trượt. Mỗi đường cắt đều gọn gàng, không có cạnh thô hay phế phẩm. Máy dễ cài đặt, an toàn khi sử dụng và phù hợp cho cả người mới bắt đầu và người dùng có kinh nghiệm. Máy hoạt động tốt trong các xưởng và phòng thí nghiệm bận rộn, nơi mà độ chính xác rất quan trọng. Máy giúp bạn có được kích thước và hình dạng chính xác mỗi lần mà không cần lo lắng. Khung máy chắc chắn và thiết kế thông minh cho phép máy hoạt động cả ngày mà vẫn cho ra những đường cắt hoàn hảo lặp đi lặp lại.

Chọn một máy cắt than chì công suất lớn.

Máy cắt than chì bằng lưỡi kim cương được chế tạo chắc chắn để có thể dễ dàng cắt xuyên qua các khối than chì cứng. Nó cho ra những vết cắt sắc bén, mịn màng và sạch sẽ mỗi lần sử dụng. Máy hoạt động với công suất cao và tốc độ nhanh, nhưng vẫn luôn đặt an toàn lên hàng đầu cho người lao động. Các tiêu chuẩn an toàn cho máy cắt than chì Các bộ phận này là một phần của cấu trúc máy, đảm bảo an toàn cho người lao động khi sử dụng. Khung máy chắc chắn, đế vững vàng và các bộ phận không dễ bị cong vênh hay gãy. Những chiếc máy này được tin dùng tại nhiều nơi làm việc, từ các xưởng nhỏ đến các nhà máy lớn, vì chúng cắt sạch, tạo ra ít bụi và giảm thiểu lãng phí vật liệu.

Giá cả và giá trị của máy cắt than chì

Giá thành của máy cắt than chì thay đổi tùy thuộc vào kích thước, thương hiệu, tốc độ cắt và các tính năng đặc biệt. Máy nhỏ có giá rẻ hơn và phù hợp với các công việc nhẹ, chẳng hạn như trong các xưởng nhỏ hoặc cho người dùng mới. Máy lớn hơn có giá cao hơn nhưng bền hơn, làm việc nhanh hơn và cho kết quả tốt nhất. Ngay cả khi giá ban đầu cao, máy sẽ tiết kiệm tiền về lâu dài nhờ khả năng cắt gọn gàng, tiết kiệm vật liệu và sử dụng được nhiều năm. Khi mua, điều quan trọng là phải kiểm tra chế độ bảo hành, dịch vụ và phụ tùng thay thế, chứ không chỉ giá cả. Hãy tìm mua máy cắt than chì từ những người bán đáng tin cậy để có được giá trị tốt nhất.

Máy móc dùng trong sản xuất điện cực

Máy cắt than chì dùng để chế tạo điện cực được chế tạo để tạo ra các hình dạng mịn và chính xác. Nó đảm bảo mỗi mảnh đều có kích thước phù hợp và giúp công nhân tiết kiệm thời gian. Bề mặt hoàn thiện gọn gàng giúp điện cực sẵn sàng sử dụng trong lò nung mà không cần thêm bước nào nữa. Điều này làm giảm lãng phí và tăng sản lượng. Nhiều người thích máy CNC hơn. máy cắt than chì Các tính năng như tự động cấp phôi, cắt nhanh và điều khiển đơn giản. Những tính năng này giúp ích cho cả các công việc nhỏ và lớn. Chúng cũng giúp giảm thiểu sai sót và đảm bảo mỗi chi tiết đều có hình dạng đồng nhất.

Ứng dụng độ tinh khiết cao

Máy cắt than chì dùng cho công việc đòi hỏi độ tinh khiết cao là thiết bị quan trọng trong phòng thí nghiệm, công việc kỹ thuật hoặc các nhà máy sạch. Những máy này được trang bị vỏ bảo vệ chống bụi và sử dụng... máy cắt than chì Với hệ thống làm mát bằng nước giúp ngăn khói, bụi và nhiệt. Điều này giữ cho nơi làm việc an toàn và sạch sẽ cho các công việc như sản xuất dụng cụ y tế, linh kiện khoa học hoặc thiết bị điện tử như tản nhiệt. Ngay cả một lượng bụi nhỏ cũng có thể gây ra thiệt hại đáng kể, vì vậy thiết kế này bảo vệ công việc và người lao động. Hệ thống làm mát bằng nước cũng giúp lưỡi dao bền hơn và làm mịn mọi vết cắt.

Tốc độ cắt so với độ chính xác

Mọi người thường hỏi liệu cắt nhanh hơn hay cắt sạch hơn thì tốt hơn. Với máy cắt than chì, cần cân bằng giữa tốc độ cắt và độ chính xác. Cắt nhanh giúp tiết kiệm thời gian nhưng có thể để lại các cạnh thô. Cắt chậm hơn cho các cạnh sắc nét hơn nhưng tốn nhiều thời gian hơn. Những máy tốt nhất sẽ giữ được sự cân bằng giữa hai yếu tố này. Hệ thống CNC hiện đại giúp lựa chọn tốc độ và bước tiến phù hợp cho cả hai. Ví dụ, máy cắt tốt nhất cho công việc tản nhiệt sử dụng hệ thống điều khiển CNC thông minh để cắt nhanh nhưng vẫn cho kết quả sạch sẽ.

Tạo hình tự động

Máy cắt và tạo hình than chì tự động giúp công việc an toàn và dễ dàng hơn. Nó giảm thiểu thao tác thủ công và hạ thấp nguy cơ tai nạn. Những máy móc này thông minh và nhanh chóng, có thể cắt nhiều hình dạng cùng một lúc. Điều này giúp tiết kiệm thời gian và cho phép công nhân làm các công việc khác. Tự động hóa cũng hỗ trợ các dự án lớn, nơi nhiều đường cắt phải có hình dạng giống nhau. Chỉ cần một người vận hành, nhiều công việc có thể được hoàn thành cùng một lúc.

Các loại máy cắt than chì được đề xuất

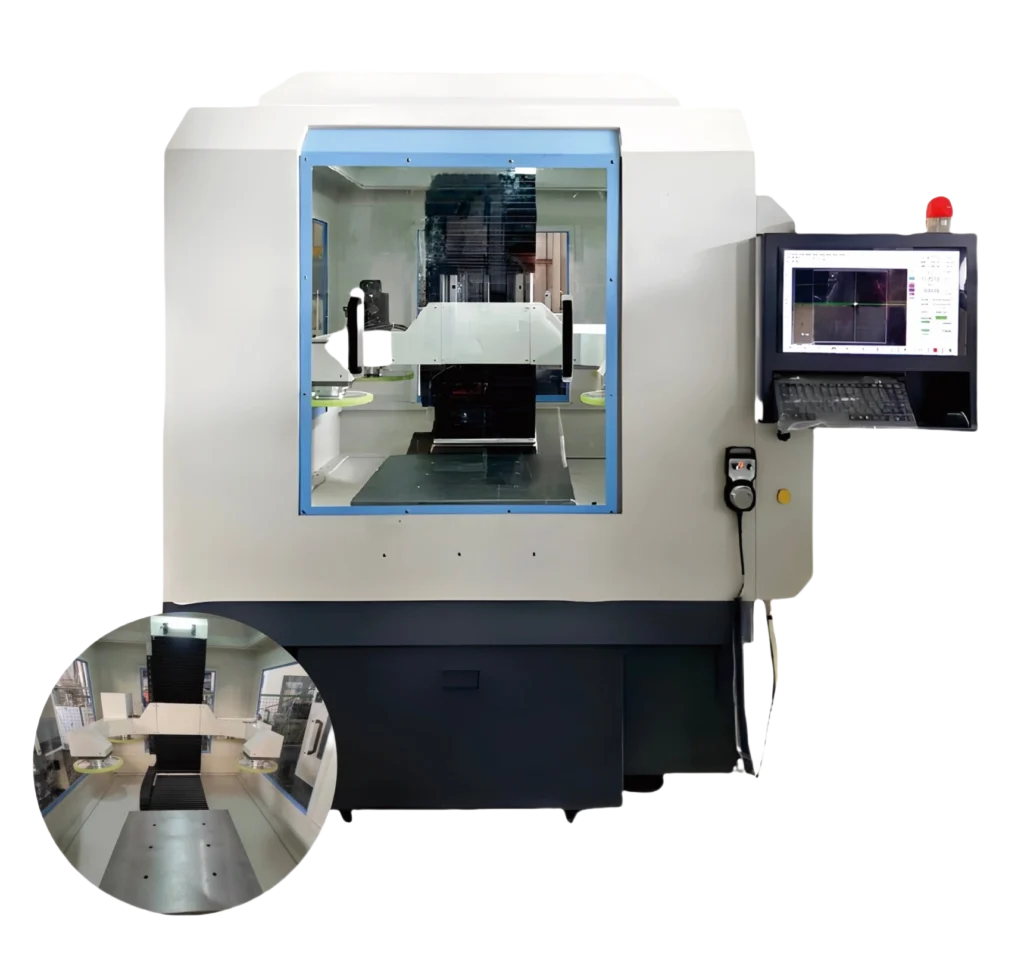

Máy cắt biên dạng ngoài bằng than chì

- Máy cắt biên dạng trong bằng than chì SVI 80-80: Tạo ra những đường cắt bên ngoài gọn gàng với các cạnh mịn.

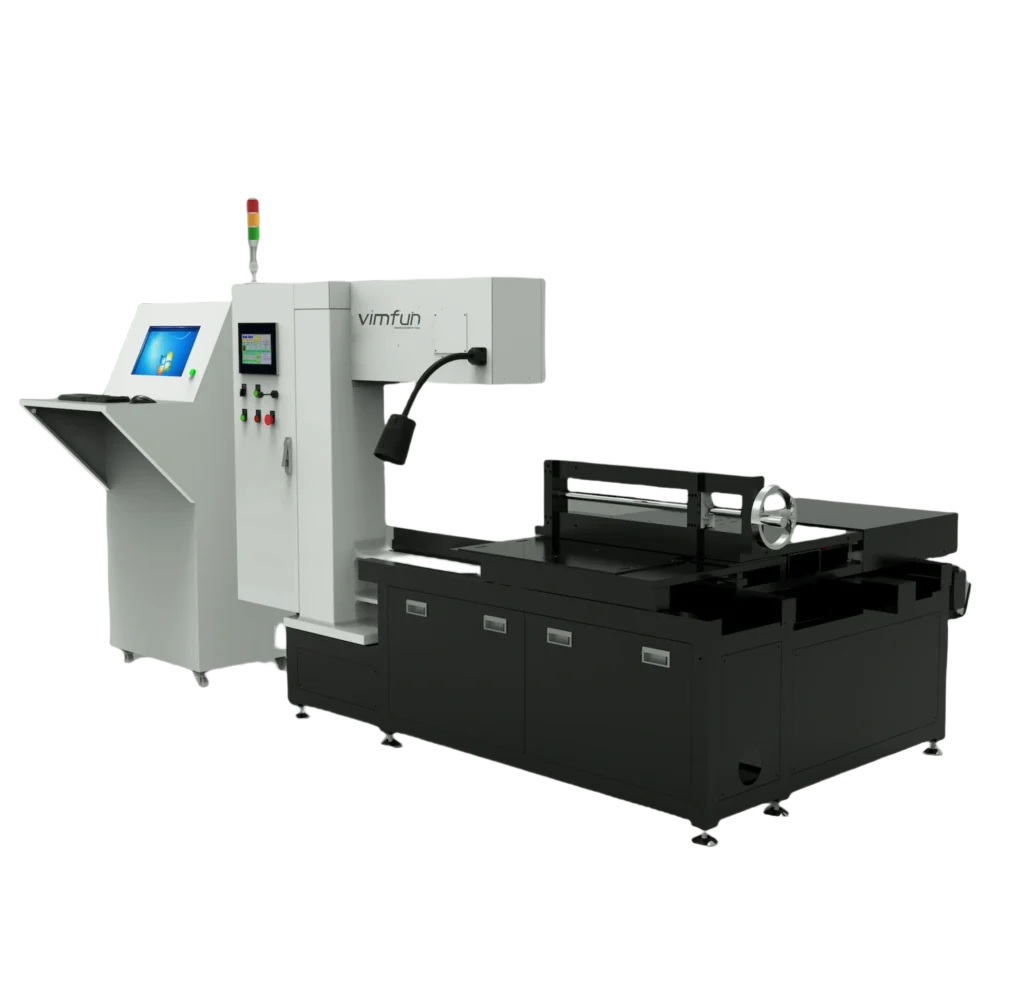

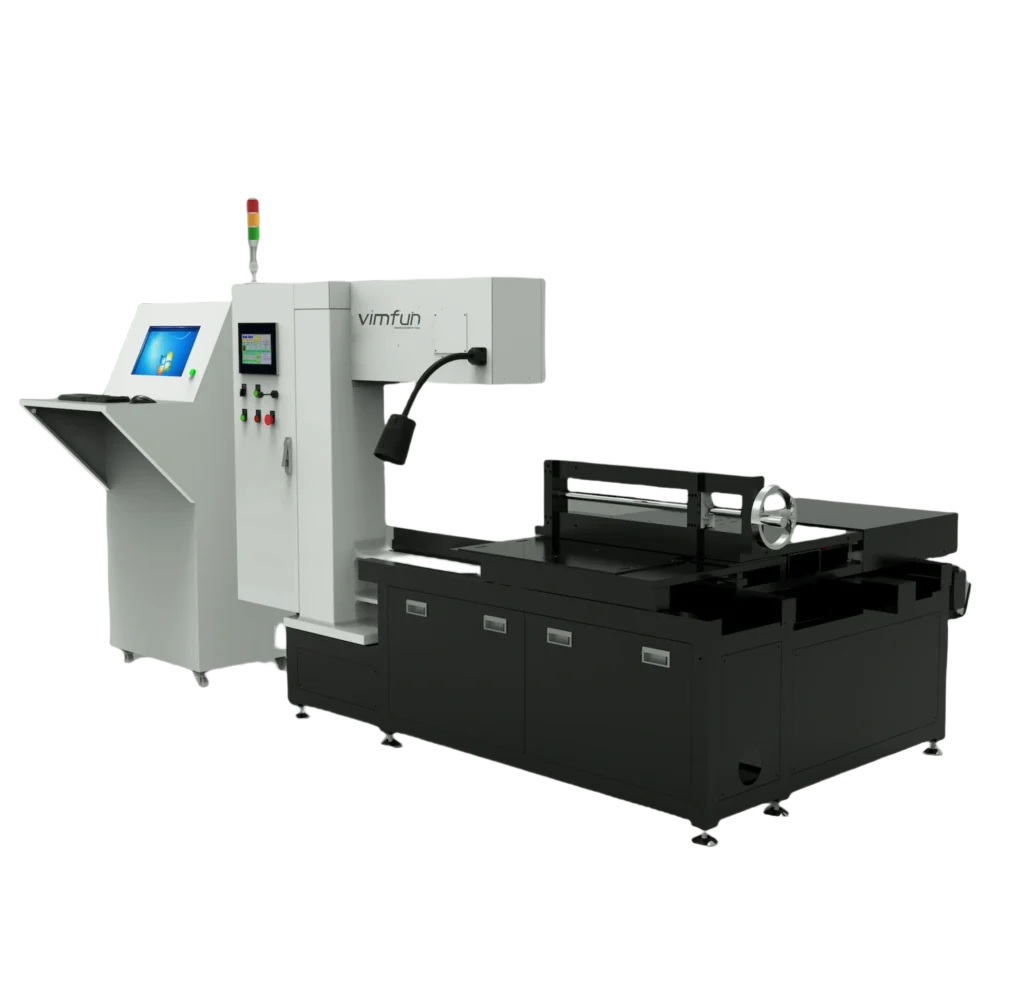

- Máy cắt than chì tự động CNC SVI 160-100: Thích hợp nhất cho công việc tự động nhanh chóng trên các dự án lớn. Cắt nhiều biên dạng cùng một lúc nhờ hệ thống CNC tiên tiến.

Máy cắt biên dạng bên trong bằng than chì

- Máy cắt biên dạng ngoài bằng than chì SVI 60-60: Nhỏ gọn nhưng chắc chắn. Dễ dàng lắp đặt và rất phù hợp cho các cửa hàng có diện tích nhỏ. Hoàn hảo cho những vết cắt nhỏ bên trong.

Máy cắt than chì

- Máy cắt than chì thẳng đứng SV 60-60Giúp cắt lát đều và gọn gàng ở mọi phía. Hệ thống lưỡi dao dọc giữ cho đường cắt thẳng và mịn.

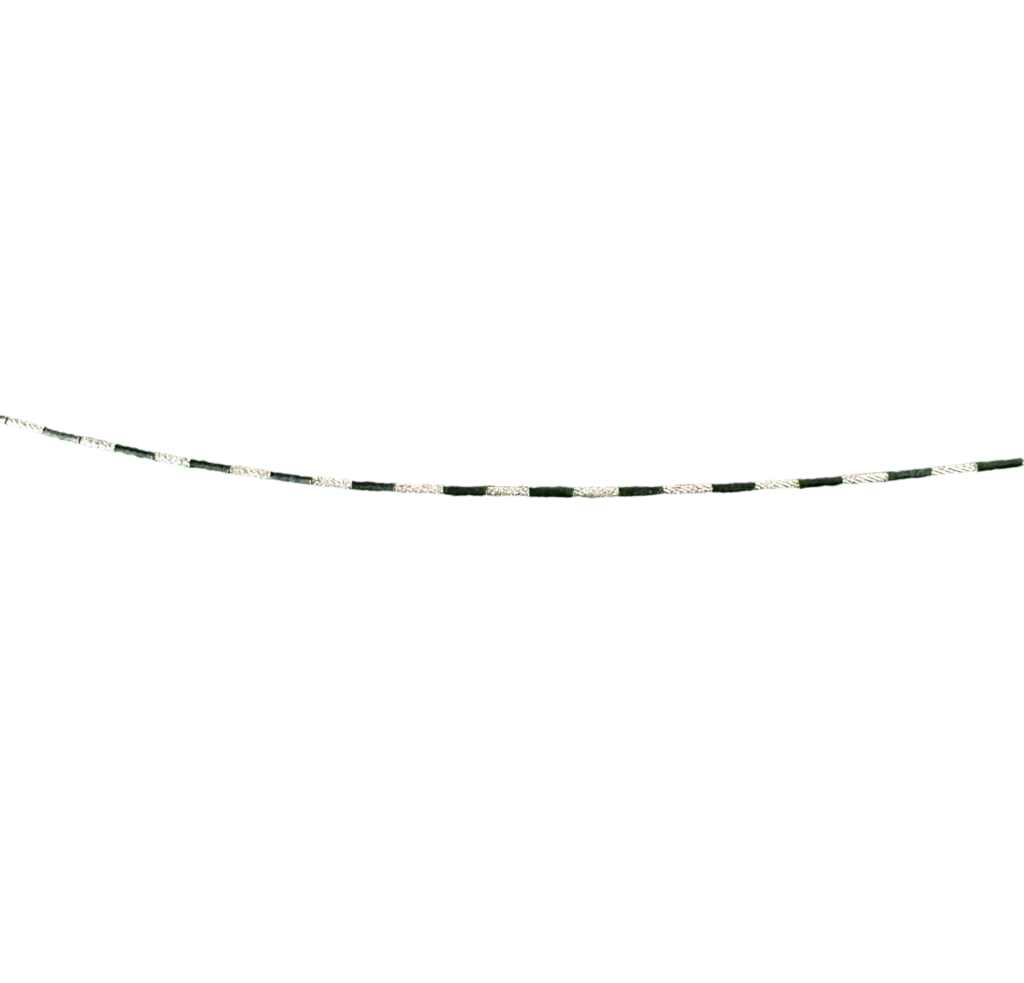

Dây cắt than chì

- Dây kim cương có thể kết nối: Chắc chắn, dễ kết nối, bền lâu và cắt gọn gàng.

- Dây kim cương dùng để cắt than chì: Được thiết kế không để lại dấu vết và tương thích với nhiều loại máy móc.

Lợi ích của dụng cụ cắt bằng than chì

| Loại dụng cụ than chì | Cách sử dụng tốt nhất | Tính năng chính |

| Máy cắt biên dạng ngoài | Các dự án lớn | Gia công CNC tự động, cắt ổn định |

| Máy cắt biên dạng bên trong | Hình dạng nhỏ | Thiết kế nhỏ gọn, dễ dàng cài đặt |

| Máy cắt lát | Những đường cắt gọn gàng | Lưỡi dao thẳng đứng, hoàn thiện gọn gàng |

| Dây cắt | Làm việc linh hoạt | Lưỡi kim cương, tuổi thọ cao |

Công dụng và lợi ích bổ sung

- Nó có thể được sử dụng cho nhiều công việc, chẳng hạn như chế tạo điện cực, làm việc trong phòng thí nghiệm và gia công các bộ phận tản nhiệt.

- Kiểm soát bụi và làm mát bằng nước giúp nơi làm việc an toàn và sạch sẽ hơn.

- Các tính năng tự động giúp giảm thiểu lãng phí và tiết kiệm thời gian.

- Được thiết kế tuân thủ các quy tắc an toàn để đảm bảo an toàn cho người sử dụng.

- Lưỡi dao và dây điện chắc chắn hơn và bền hơn, giúp tiết kiệm chi phí.

Địa điểm lý tưởng để mua máy cắt than chì

Đúng vậy Máy cắt CNC Tính năng này có thể thay đổi cách thức thực hiện công việc. Những máy móc này kết hợp tốc độ, độ an toàn và khả năng cắt chính xác. Bạn có thể lựa chọn từ các dòng máy SVI 80-80, SVI 160-100, SVI 60-60 hoặc SV 60-60 tùy theo nhu cầu. Sử dụng dây kim cương có thể kết nối giúp công việc trở nên tốt hơn và bền lâu hơn. Hãy coi chi phí như một khoản đầu tư, vì những máy móc này sẽ tiết kiệm tiền bạc và thời gian trong nhiều năm. Để có giá tốt nhất và được hỗ trợ, hãy truy cập trang web của chúng tôi. VIMFUN Hãy truy cập trang web và tìm mua chiếc máy giúp công việc của bạn nhanh hơn, an toàn hơn và sạch hơn.

Chiếc máy mạnh mẽ này kết hợp sức mạnh và độ chính xác trong một công cụ bền bỉ. Nó giúp mọi công việc trở nên dễ dàng, nhanh chóng và chính xác, đồng thời tiết kiệm thời gian và vật liệu. Sử dụng nó để có được những đường cắt hoàn hảo mỗi lần với ít công sức hơn và sự tự tin hơn trong mọi nhiệm vụ.

Câu hỏi thường gặp

- Dây kim cương có thể sử dụng được trong bao lâu?

Nếu sử dụng ở tốc độ phù hợp và có hệ thống làm mát tốt, sản phẩm sẽ có tuổi thọ cao. Nếu được bảo quản cẩn thận, tuổi thọ của sản phẩm còn kéo dài hơn nữa.

- Những máy này có thể cắt tản nhiệt được không?

Máy cắt than chì tốt nhất cho công việc chế tạo tản nhiệt được thiết kế chuyên dụng và tạo ra các cạnh sắc nét.

- Những máy móc này có cần làm mát bằng nước không?

Đúng vậy, máy cắt than chì có hệ thống làm mát bằng nước giúp giảm bụi, giữ nhiệt độ thấp và làm cho lưỡi dao bền hơn.

- Tôi có thể mua những chiếc máy này ở đâu?

Bạn có thể mua chúng trên trang web VIMFUN để được giao dịch an toàn và hỗ trợ đầy đủ.

- Những chiếc máy này có dễ sử dụng cho người mới không?

Máy CNC có hệ thống điều khiển và dẫn hướng đơn giản, vì vậy ngay cả người lao động mới cũng học rất nhanh.