The vertical graphite cutting machine price is essential for many factories and small shops. Graphite is a soft material, but it can break easily. It is used to make molds and electronic parts. Graphite needs special machines for cutting. Standard machines can damage it. A vertical cutting machine cuts graphite in a safe and controlled manner. It also gives clean results. Many buyers seek a reliable machine at an affordable vertical graphite cutting machine price. Knowing the machine helps people make better choices.

Why Vertical Graphite Cutting Machines Are Popular

These cutting machines are popular due to their ease of use. They are also very stable during cutting. The vertical design securely holds the graphite block in place. This reduces shaking while cutting. It helps make clean and accurate cuts. These machines are used as graphite block cutting machines in many factories. They also save space in the workshop. Because of these reasons, many people search for a good vertical graphite cutting machine price.

Importance of Diamond Wire Cutting Machine

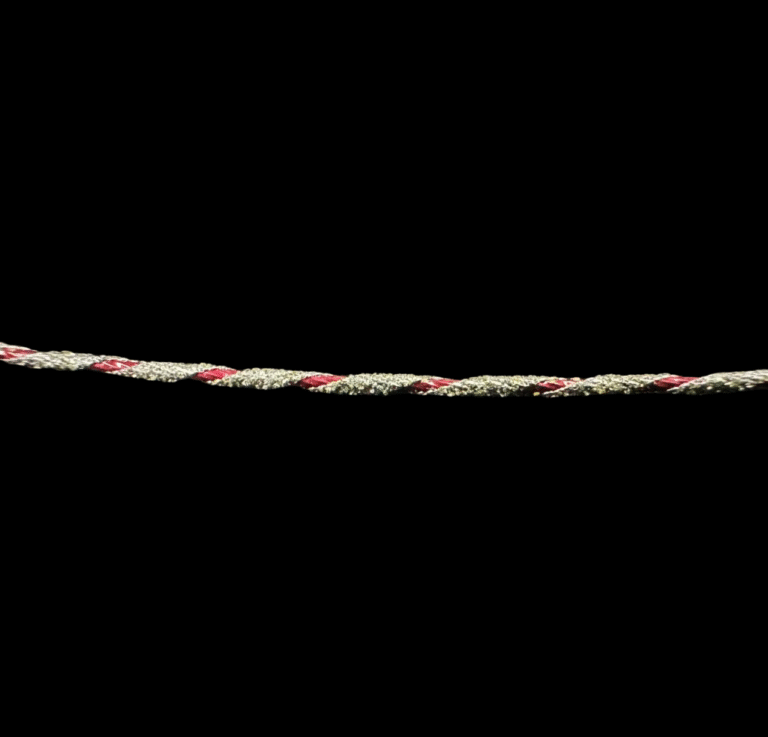

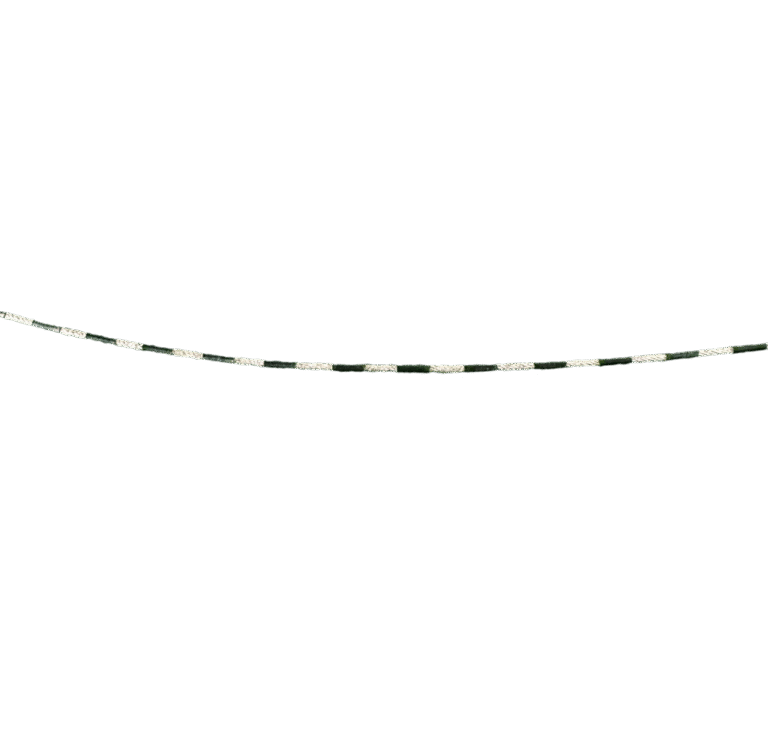

A diamond wire cutting machine is handy for cutting graphite smoothly. It uses a thin wire with a diamond coating to cut the material gently. This method does not break the graphite easily. It also creates smooth surfaces and clean edges. Diamond wire cutting is suitable for high-precision graphite cutting work. It also helps reduce dust in the working area. This makes the cutting process safer and cleaner for workers.

Benefits of Vertical Diamond Wire Saw Design

A vertical diamond wire saw combines vertical structure with diamond wire cutting technology. This design helps maintain a stable and balanced cutting process. It is invaluable for EDM graphite cutting and detailed mold work. The vertical setup allows even pressure on the graphite block. This improves cutting accuracy and reduces waste. Many factories prefer this design because it supports long working hours and consistent quality. These features add value to the vertical graphite cutting machine price.

CNC Graphite Cutter for Easy Operation

A CNC graphite cutter uses computer control to manage cutting speed and direction. This makes the cutting process easy and repeatable. CNC control helps reduce human mistakes during cutting. It is beneficial for mold-grade graphite slicing and complex shapes. Many CNC machines use an endless diamond wire saw to allow continuous cutting. This saves time and improves productivity. CNC systems help factories produce the same quality every time.

Low-Dust Graphite Cutting for Safety

Graphite dust can be hazardous if it becomes airborne in the workspace. Low-dust graphite cutting is crucial for worker safety. Modern graphite cutting machines are designed to minimize dust during the cutting process. Diamond wire cutting creates less dust compared to blade cutting. Enclosed cutting areas and dust collection systems help keep the air clean. This also protects the machine parts from damage. Clean working conditions improve machine life and cutting quality.

SV 60-60 Vertical Graphite Cutting Machine

The SV 60-60 Vertical Graphite Cutting Machine is designed for stable and accurate graphite cutting. It is suitable for factories that need good performance at a reasonable cost. This machine supports diamond wire cutting and vertical operation. It is used for EDM graphite cutting and precision mold work. The vertical graphite cutting machine price of this model is affordable for its features and quality.

Main features:

- Vertical Diamond Wire Saw structure for stable cutting

- Supports High-Precision Graphite Cutting

- Works well for the Graphite Block Cutting Machine needs

- Designed for Low-Dust Graphite Cutting

- Easy to operate and maintain

Industrial Uses of Vertical Graphite-Cutting Machines

These cutting machines are used in many industries. Mold factories use them to cut graphite electrodes. Electronics companies use graphite parts for heat control. The energy and aerospace industries also use graphite materials. The SV 60-60 machine fits these applications very well. It provides stable cutting and clean results. Because it supports many industries, it offers good value for its price.

Factors That Affect Vertical Graphite Cutting Machine Price

Many factors affect the vertical graphite cutting machine price. Machine size, cutting capacity, and CNC control all change the cost. Diamond wire quality also plays an important role. Machines with better dust control and automation usually cost more. However, they save money in the long run by reducing waste and labor costs. Choosing a machine like the SV 60-60 helps strike a balance between price and performance. Buyers should always consider long-term use.

Choose Vimfun for Easy and Affordable Graphite Cutting

At Vimfun, we help you choose the right machine at the right price. We recognize that both good quality and low cost are essential. Our cutting machines are easy to use and give clean cuts. They are strong and made to last a long time. We design our machines for small and large factories. If you want a fair vertical graphite cutting machine price, Vimfun is a wise choice. Visit our website to learn more and talk to our team. Choose Vimfun to work better, save time, and grow your business with ease.

Choosing a vertical graphite-cutting machine is not just about price; it’s also about quality. The SV 60-60 cuts well, produces little dust, and operates steadily. It is suitable for modern factories.

FAQs

- Why is vertical cutting better than other types?

Vertical cutting holds the graphite steady, reduces shaking, and gives more accurate cuts.

- What affects the vertical graphite cutting machine price?

Machine size, cutting method, CNC control, and dust control all change the price.

- What is diamond wire cutting?

It uses a wire with diamonds to cut graphite smoothly and cleanly with less dust.

- Can it be used for molds and electrodes?

Yes, it works well for mold-grade graphite slicing and EDM graphite cutting.

- Is it safe for workers?

Yes, it has low-dust cutting and safe operation for a clean workplace.