A trusted Vertical Graphite Cutting Machine manufacturer helps many industries cut graphite safely and cleanly. Graphite is a fragile yet fragile material. It may break or crack if cutting is not done correctly. Many companies prefer crisp edges and accurate sizes. This is why choosing the right manufacturer is very important. A good Vertical Graphite Cutting Machine manufacturer makes machines that work smoothly and last long. These machines help users save time, reduce waste, and get better results every day.

Importance of Precision in Graphite Cutting

Graphite needs careful cutting. It can chip easily. A small mistake can damage the whole piece. Precision cutting helps maintain the shape and size. A Vertical Graphite Cutting Machine manufacturer designs machines that cut slowly and evenly. Diamond Wire Saw processes are especially helpful here. They cut carefully and keep the surface smooth. This is very important for EDM Graphite Cutting. EDM work requires accurate shapes. Clean cuts make equipment operate well later.

Advanced Vertical Cutting Technology

Vertical cutting is very useful for graphite. The material stays stable during cutting. A Vertical Wire Saw moves in a straight, controlled manner. This reduces pressure on the graphite. It also lowers the risk of cracks. Minimal material loss cutting is supported by vertical machines. Less material is wasted. A CNC Graphite Cutter makes cutting even easier. Paths and sizes may be provided by the user. The machine follows the plan perfectly every time.

Solutions for Graphite Block and Large-Sized Cutting

Graphite Block Cutting needs strong machines. The blocks are heavy and dense. Large Graphite Cutting needs even more support. A trusted Vertical Graphite Cutting Machine manufacturer builds machines with solid frames. These machines do not shake during work. The wire stays tight and steady. This helps cut large and wide graphite blocks effortlessly. Large graphite slabs may be sliced into clean, smooth pieces of the desired size.

Applications Across Multiple Industries

Vertical Graphite Cutting Machine manufacturers are used in many fields. Battery factories use graphite parts every day. Electronics factories need clean graphite pieces. The aerospace and automotive industries also use graphite for thermal control. EDM Graphite Cutting is very common in mold manufacturing. A graphite slab slicing machine helps in the making of perfectly flat sheets. These sheets are used where exact thickness is needed. One machine can support many industries.

Efficiency and Reduced Material Waste

Modern cutting machines focus on minimizing material waste. Diamond Wire Saw cutting uses a very thin wire. The cut line is small. This means less graphite is lost. This is called Minimal Material Loss Cutting. Less waste means lower cost. It also helps the environment. A good Vertical Graphite Cutting Machine manufacturer designs machines that operate quickly and safely. The wire lasts longer. Energy use stays low. This helps factories save money over time.

CNC Automation and Smart Control Systems

CNC systems make cutting easy and accurate. A CNC Graphite Cutter allows users to enter sizes and shapes on a screen. The machine does the rest. It cuts the same way every time. This is helpful for large production work. Smart control systems show cutting speed and wire tension. They help avoid mistakes. Even new operators can use the machine with basic training.

SV 60-60 Vertical Graphite Cutting Machine

The SV 60-60 from a trusted Vertical Graphite Cutting Machine manufacturer is designed for clean, accurate graphite cutting. It has a strong body and a stable design. The machine works well for Graphite Block Cutting and EDM Graphite Cutting. It can also handle large graphite cutting jobs. The vertical structure keeps the material steady during work. This helps produce smooth cuts with less damage.

Features:

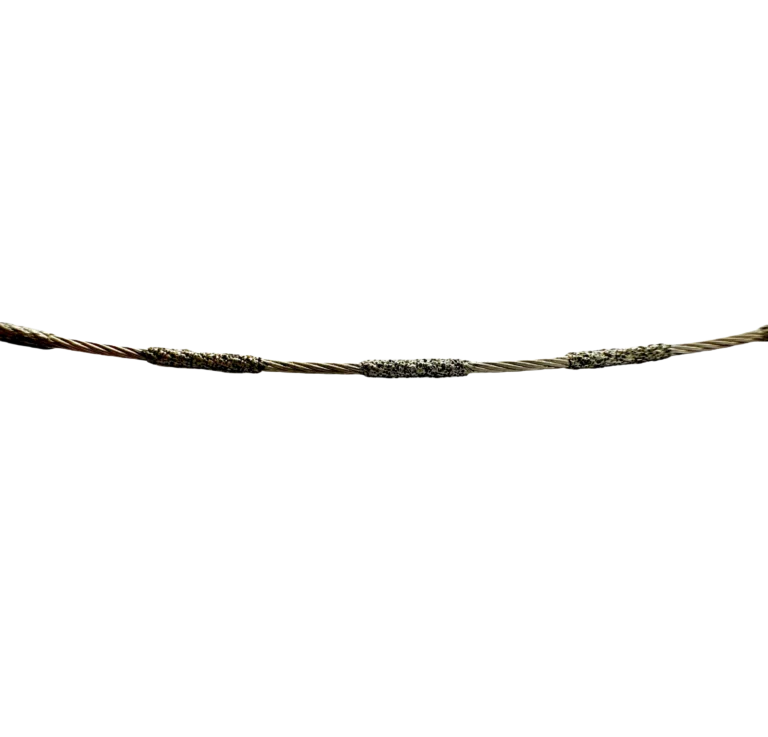

- Uses a Diamond Wire Saw for clean and smooth cutting

- Supports Minimal Material Loss Cutting and saves raw graphite

- The CNC control system makes the operation easy and repeatable

Why Choose a Trusted Manufacturer

A trusted Vertical Graphite Cutting Machine manufacturer offers more than machines. They offer support and experience. They understand real factory needs. They help choose the right machine size and type. Good manufacturers provide training and service support. Their machines work longer with fewer problems. This gives buyers peace of mind and better long-term value.

Choose a Vertical Graphite Cutting Machine manufacturer

Ready to improve how you cut graphite. Vimfun is a trusted company that makes strong and easy-to-use cutting machines. Our machines give clean cuts and waste less material. They are safe, stable, and made to last a long time. Many industries use our machines for EDM work and large graphite cutting. When you choose Vimfun, you get good quality, helpful support, and fair value for your money. Visit the website today to learn more. Let us help your factory work faster, cut better, and grow step by step with confidence.

Graphite cutting is getting better. Machines are faster, easier to use, and stronger. Good makers make these machines to work well for a long time.

FAQs

Why is precision important in graphite cutting?

Graphite can break easily, so cutting must be smooth and exact.

What is a Diamond Wire Saw?

It is a wire with a diamond coating that cuts graphite gently and reduces waste.

What is Minimal Material Loss Cutting?

It is a cutting method that wastes very little graphite.

What does the CNC Graphite Cutter do?

It allows the machine to cut shapes and sizes automatically with high accuracy.

What is special about the SV 60-60 machine?

It cuts large graphite blocks safely, saves material, and is easy to use with CNC.

Why choose a trusted manufacturer?

They give good machines, support, and long-lasting service.