Cắt những vật liệu cứng như than chì, gốm sứ và silicon có thể rất khó khăn. Những vật liệu này cực kỳ bền chắc, nhưng cũng có thể bị vỡ nếu không cẩn thận. Đó là lý do tại sao máy cắt thông minh ra đời. máy cắt dây kim cương thẳng đứng Nó rất tiện dụng. Nó giúp cắt các vật liệu này nhanh chóng, chính xác và an toàn.

Vimfun? Họ là lựa chọn hàng đầu cho máy cắt dây kim cương dùng để xử lý than chì và các vật liệu cứng khác. Họ tập trung vào việc sử dụng công nghệ tiên tiến, đảm bảo chất lượng và chế tạo máy móc phù hợp với nhu cầu của doanh nghiệp. Máy móc của họ giúp các công ty trên toàn thế giới cắt vật liệu nhanh hơn, sạch hơn và chính xác hơn.

Cái này thiết bị cắt đá chính xác Đây là giải pháp tuyệt vời cho các ngành công nghiệp như bán dẫn, pin lithium, hàng không vũ trụ và sản phẩm carbon. Nó giúp tiết kiệm thời gian, giảm thiểu lãng phí và đảm bảo mọi vết cắt đều giống nhau.

Máy cắt dây kim cương thẳng đứng siêu ngầu

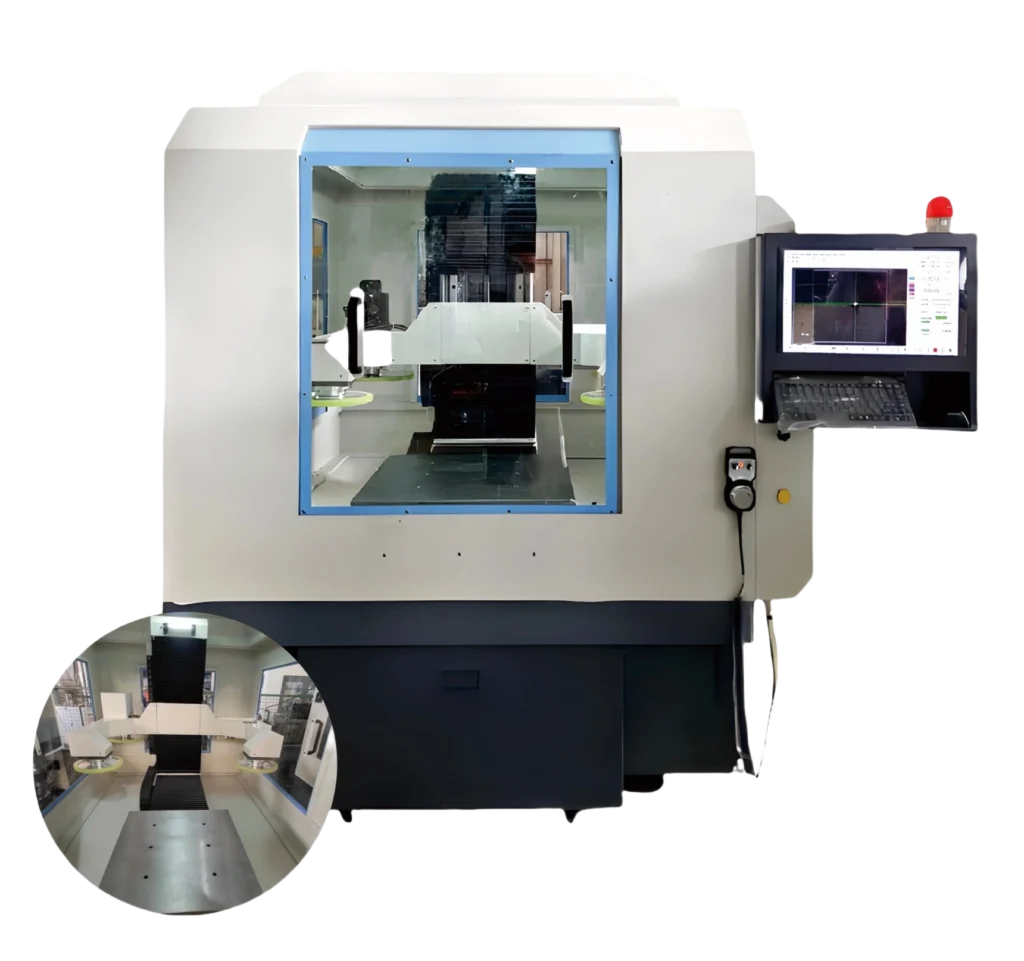

Máy cắt than chì thẳng đứng (SH 60-60Máy này được chế tạo để cắt các khối than chì cỡ trung bình và lớn một cách nhanh chóng và chính xác cao.

Nó rất phù hợp cho than chì dùng cho pin, khối EDM và các tấm than chì dùng trong khuôn đúc. Thêm vào đó, thiết kế thẳng đứng giúp tiết kiệm không gian và dễ dàng nạp liệu từ phía trước hoặc phía trên.

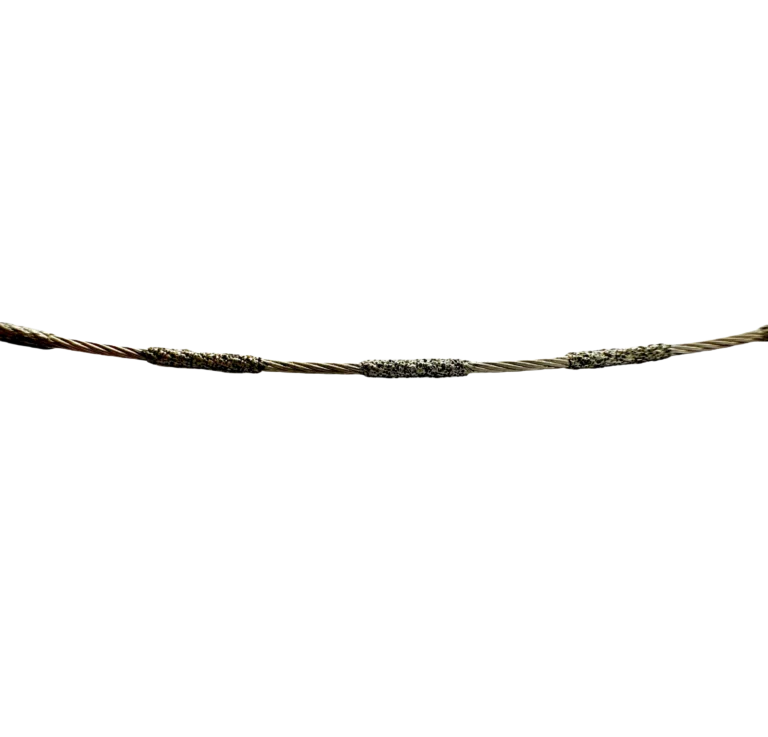

Các máy cưa dây kim cương tự động Nó sử dụng một loại dây kim cương vô tận. Nó giống như một vòng dây có gắn kim cương, di chuyển cực nhanh theo một hướng. Điều này tạo ra những đường cắt mịn, sạch và không lãng phí nhiều vật liệu. Nó không để lại những vết xước như khi dùng cưa dây thông thường và giữ cho bề mặt luôn phẳng mịn.

Với hệ thống điều khiển tự động CNC, máy SV 60-60 có thể cắt nhiều lần với độ dày chính xác. Hệ thống kẹp dọc giúp giữ cố định khối gỗ, giảm rung lắc và đảm bảo mỗi đường cắt đều chính xác. Máy có thể làm việc với các khối gỗ có kích thước lên đến 600mm × 600mm và cắt với độ chính xác ±0.05mm.

Tại sao sự chính xác lại quan trọng khi cắt những vật liệu cứng?

Độ chính xác tuyệt đối là vô cùng quan trọng khi cắt các vật liệu cứng. Ngay cả một sai sót nhỏ cũng có thể làm hỏng mọi thứ. Ví dụ, trong sản xuất chất bán dẫn, các lát than chì và silicon cần phải chính xác tuyệt đối. Nếu cạnh không đều hoặc độ dày không đúng, nó có thể gây ra những vấn đề lớn.

Sử dụng máy cắt dây kim cương thẳng đứng Đảm bảo các đường cắt được mịn và chính xác. Điều này giúp giảm thiểu các vết nứt và bề mặt không đều. Với các đường cắt chính xác, các công ty tiết kiệm vật liệu, giảm thiểu sai sót và tạo ra sản phẩm tốt hơn.

Nguyên lý hoạt động của máy cắt dây kim cương thẳng đứng

Các Công nghệ cắt lát tấm silicon Sử dụng một sợi dây mỏng được phủ các viên kim cương công nghiệp. Sợi dây này chuyển động liên tục theo một hướng. Các vật liệu như than chì hoặc silic được đặt trên một chiếc bàn chắc chắn.

Khi dây cắt di chuyển, nó nhẹ nhàng và đều đặn cắt xuyên qua vật liệu. Thiết kế thẳng đứng giúp máy ổn định, và hệ thống điều khiển CNC di chuyển bàn máy với độ chính xác cao. Hệ thống làm mát và máy hút bụi giữ cho khu vực cắt luôn sạch sẽ.

Những tính năng tuyệt vời và điều gì làm nên sự xuất sắc của giải pháp cắt của chúng tôi

Máy cắt dây kim cương thẳng đứng của Vimfun được tích hợp nhiều tính năng tuyệt vời. Máy có độ chính xác cao, đảm bảo bạn luôn có được bề mặt phẳng và độ dày chính xác mỗi lần sử dụng. hệ thống cắt dây tốc độ cao Có thể tạo ra những đường cắt thẳng hoặc những hình dạng phức tạp hơn một chút.

Máy có hệ thống giữ dây căng, giúp duy trì áp suất ổn định trong suốt quá trình làm việc dài. Khung máy chắc chắn giúp giảm rung lắc và tăng độ chính xác. Hệ thống làm mát và hút bụi giúp giữ cho khu vực làm việc luôn sạch sẽ.

Tự động hóa tiên tiến giúp cắt nhanh hơn và sạch hơn.

Tự động hóa giúp máy dễ sử dụng và hiệu quả. Hệ thống điều khiển CNC cho phép bạn thiết lập tốc độ, lực căng và đường cắt. Sau đó, máy sẽ tự động thực hiện công việc, giúp giảm thiểu sai sót và công sức.

Máy có thể thực hiện các thao tác cắt nhiều lát cùng lúc, giúp tăng tốc độ và năng suất. Hệ thống làm mát và hút bụi hoạt động cùng với hệ thống tự động hóa để giữ cho khu vực luôn sạch sẽ. Máy thậm chí còn có các cảm biến thông minh theo dõi hoạt động và dừng máy nếu có sự cố xảy ra.

Tốc độ, độ chính xác và khả năng tự động hóa này giúp các công ty đạt được kết quả nhanh chóng và chính xác mà không cần phải tốn nhiều công sức.

Vật liệu và ngành công nghiệp ưa chuộng cắt dây kim cương

Các máy cắt dây kim cương thẳng đứng Máy cắt này hoạt động rất tốt với nhiều loại vật liệu cứng. Nó có thể cắt than chì, silicon, gốm sứ, vật liệu composite carbon, sapphire và các bộ phận của pin lithium. Những vật liệu này rất khó cắt bằng các dụng cụ thông thường.

Các ngành công nghiệp sử dụng máy này bao gồm bán dẫn, hàng không vũ trụ, điện tử, lưu trữ năng lượng và sản xuất carbon. Các nhà sản xuất pin lithium dựa vào máy này để tạo ra các đường cắt chính xác như than chì. Các công ty hàng không vũ trụ và điện tử sử dụng nó để sản xuất các bộ phận bằng carbon và gốm sứ. Máy Vimfun cung cấp kết quả ổn định, chất lượng cao cho tất cả các ngành công nghiệp này.

Các cách sử dụng khác nhau của máy cắt dây kim cương

Cái này máy cắt dây kim cương thẳng đứng Nó thực sự rất đa năng. Trong các nhà máy bán dẫn, nó cắt các tấm silicon và điện cực than chì. Khi sản xuất pin lithium, nó cắt các khối than chì thành các tấm mỏng và đều. Nó cũng xử lý các vật liệu được sử dụng cho gốm sứ và sapphire trong ngành hàng không vũ trụ và điện tử.

Máy có thể tạo ra nhiều hình dạng khác nhau, không chỉ là những đường cắt thẳng. Điều này rất quan trọng đối với các bộ phận được chế tạo theo yêu cầu. Khi bạn có thể sử dụng một máy cho tất cả các loại vật liệu này, bạn sẽ tiết kiệm được tiền bạc và không gian. Máy Vimfun được chế tạo để sử dụng nhiều lần.

Các nút điều khiển dễ sử dụng và các tính năng an toàn.

Các máy cắt dây kim cương thẳng đứng Nó rất dễ sử dụng. Nó có màn hình cảm ứng để bạn nhập thông tin cần cắt, theo dõi quá trình và lưu cài đặt. Ngay cả khi bạn không có nhiều kinh nghiệm, bạn vẫn có thể sử dụng được.

An toàn cũng là một vấn đề rất quan trọng. máy cắt đá cẩm thạch và đá granit Máy có chức năng tự động tắt, bảo vệ quá tải và các nút bấm để dừng ngay lập tức nếu có sự cố. Hệ thống hút bụi và làm mát giúp bảo vệ cả người sử dụng và vật liệu. Máy hoạt động êm ái, ít rung động, tạo môi trường làm việc an toàn hơn.

Tại sao nên chọn chúng tôi cho nhu cầu cắt dây kim cương của bạn?

Vimfun là nhà sản xuất máy cắt dây kim cương thẳng đứng đáng tin cậy. Chúng tôi chú trọng công nghệ, độ chính xác và thiết kế máy móc dựa trên cách thức sử dụng. Máy móc của chúng tôi giúp các ngành công nghiệp trên toàn thế giới cắt vật liệu nhanh hơn, sạch hơn và chính xác hơn.

Của chúng tôi giải pháp cắt vật liệu bán dẫn Máy móc của chúng tôi được chế tạo để bền bỉ và dễ bảo trì. Mỗi máy đều trải qua các bài kiểm tra để đảm bảo chất lượng và an toàn. Chúng cũng giúp khách hàng tận dụng tối đa các lợi ích của máy móc. Chọn Vimfun nghĩa là bạn đang sở hữu công nghệ tiên tiến giúp tăng năng suất, giảm thiểu lãng phí và mang lại kết quả đáng tin cậy.

Tóm lại

Máy cắt dây kim cương thẳng đứng thông minh là thiết bị không thể thiếu trong các nhà máy hiện nay. Nó kết hợp tốc độ, độ chính xác, tự động hóa và an toàn để mang lại cho bạn những kết quả tuyệt vời. Vimfun Máy móc giúp việc cắt than chì, silicon, gốm sứ và các vật liệu cứng khác trở nên đơn giản và đáng tin cậy hơn.

Từ chất bán dẫn đến pin lithium, hàng không vũ trụ và các sản phẩm carbon, lĩnh vực này hiệu quả của quy trình cắt dây kim cương Mang lại những đường cắt sạch sẽ, chính xác và ổn định mọi lúc. Dễ điều khiển, có hệ thống an toàn tốt và sẽ không bị hỏng.

Với công nghệ của Vimfun, những vật liệu trước đây khó cắt giờ đây trở nên dễ dàng. Tất cả là để sử dụng nó nhằm tạo ra những sản phẩm tốt hơn và những điều mới mẻ.

Câu hỏi thường gặp

Nó có thể cắt được những gì?

Than chì, silic, gốm sứ, sapphire và vật liệu composite carbon.

Máy này có phải là máy tự động không?

Đúng vậy, nó được điều khiển bằng CNC và hoạt động tự động.

Độ chính xác của việc cắt như thế nào?

Nó cực kỳ chính xác, mượt mà và phẳng.

Nó có thể xử lý các bộ phận lớn hoặc phức tạp không?

Đúng vậy, nó có thể xử lý các khối lớn và các đường cắt thẳng hoặc phức tạp.

Ai sản xuất chiếc máy này?

Vimfun chuyên sản xuất máy cắt dây kim cương dùng cho các vật liệu khó cắt.